Micro pressure sensor chip and preparation method thereof

A micro-pressure sensor and chip technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, instruments, microstructure technology, etc., can solve the problem of susceptibility to the influence of parasitic capacitance, increase of sensor nonlinearity, and increase of signal processing Difficulty and other issues, to achieve the effect of easy processing, good linearity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

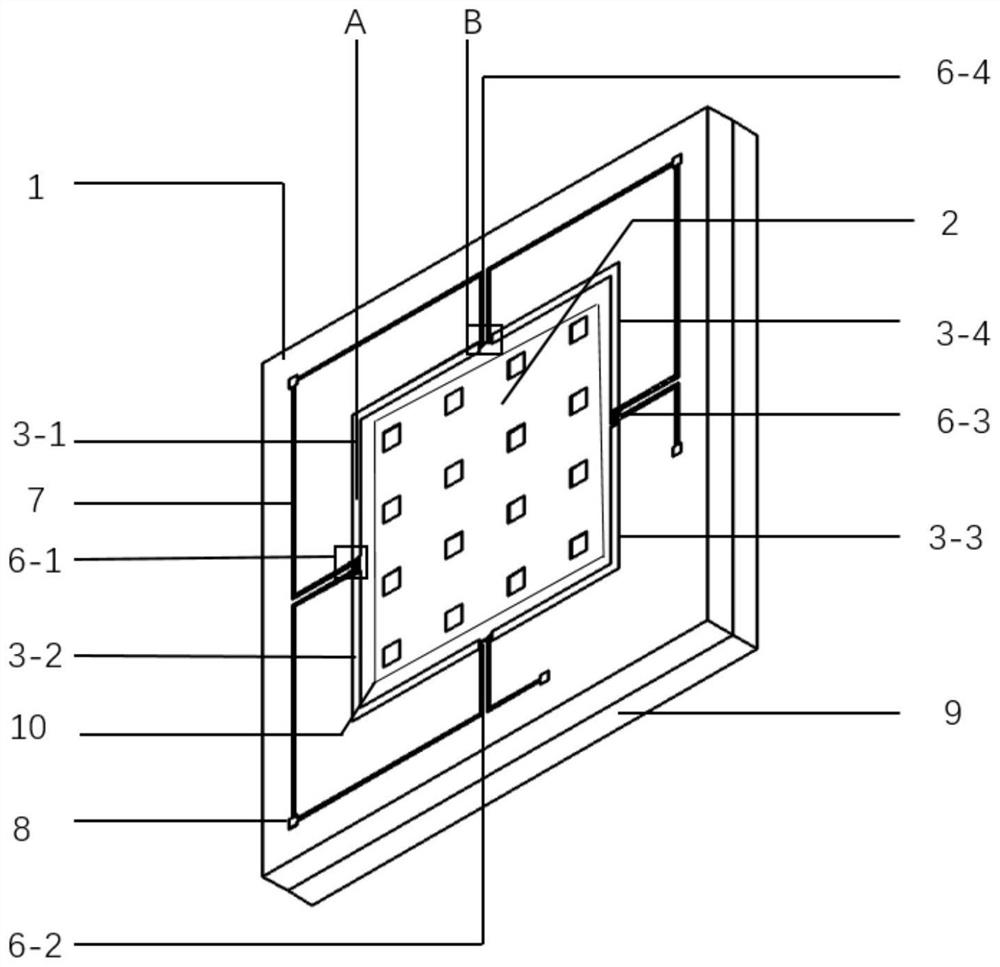

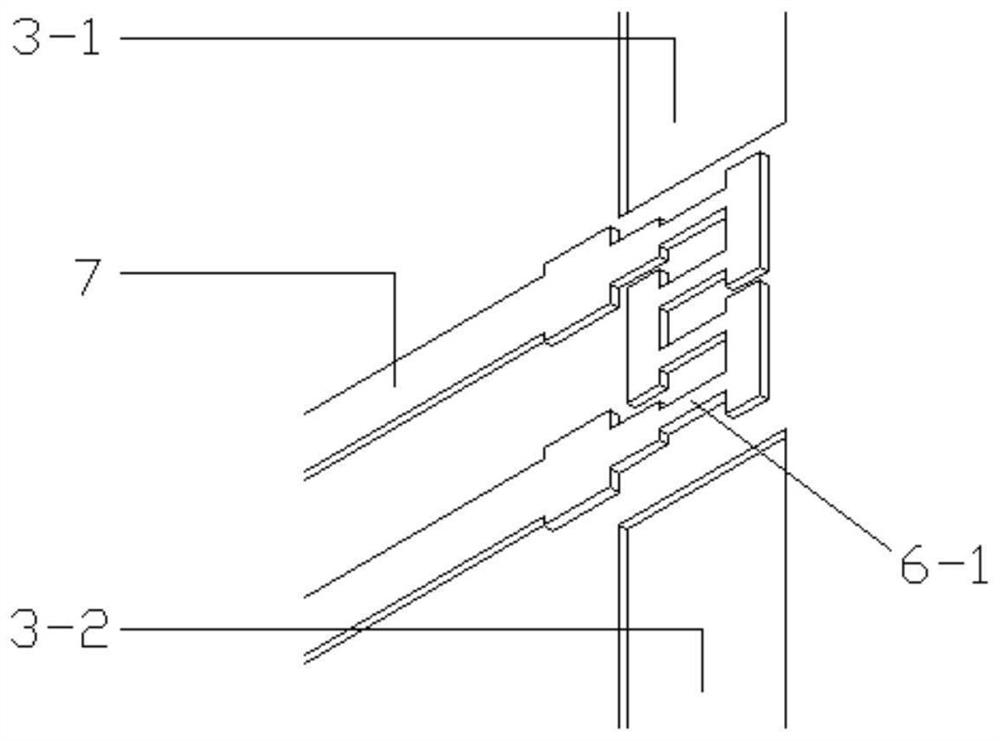

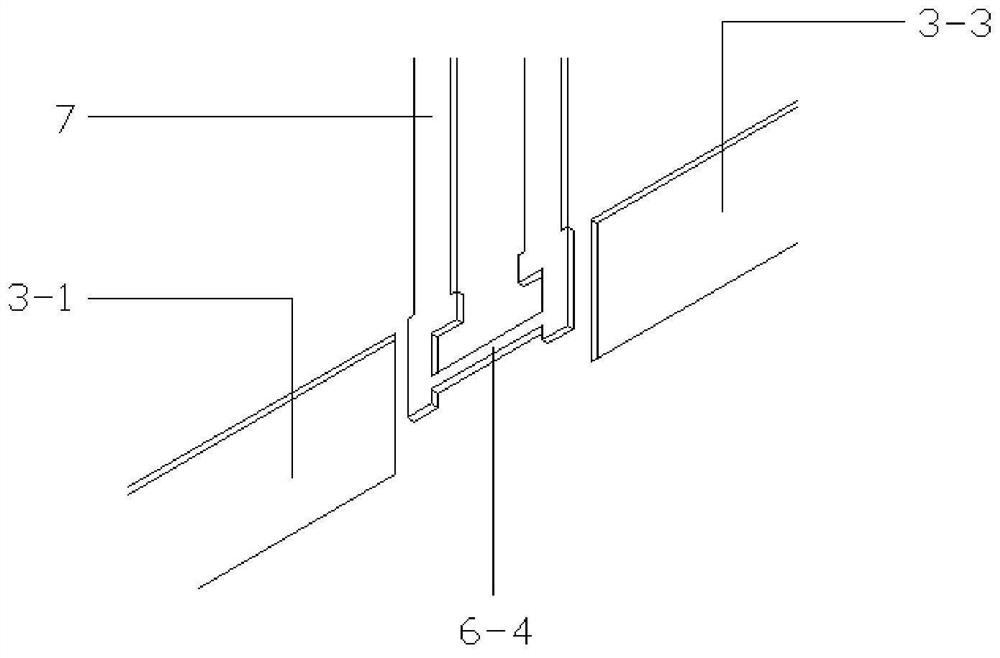

[0045] In order to make the purpose and technical solutions of the present invention clearer and easier to understand. Below in conjunction with the accompanying drawings and examples,

[0050] The depth of the stress adjustment grooves in the array 10 is 20% to 80% of the thickness of the stress film 2 . The first stress concentration groove to the first

[0062] 7) Referring to FIG. 7g, the back surface of the substrate 1 is bonded to the top surface 11 of the anti-overload glass 9 to obtain a micro-pressure sensor chip.

[0064] FIG. 8 is a schematic diagram of the cross-sectional structure relationship of the present invention in an unloaded state. Referring to Figure 9, the sensor is at a slight pressure P

[0074] 7. Chip shape: 5mm×5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sensitivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com