A beam-membrane structure high-voltage electrostatic field sensor chip based on the pressure-sensitive principle

A high-voltage electrostatic field and sensor chip technology, applied in electrostatic field measurement and other directions, can solve problems such as low frequency or low electrostatic field sensitivity, inability to achieve mass production, sensor supply, etc., to improve measurement sensitivity and increase the stress concentration in sensitive areas. effect, single low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

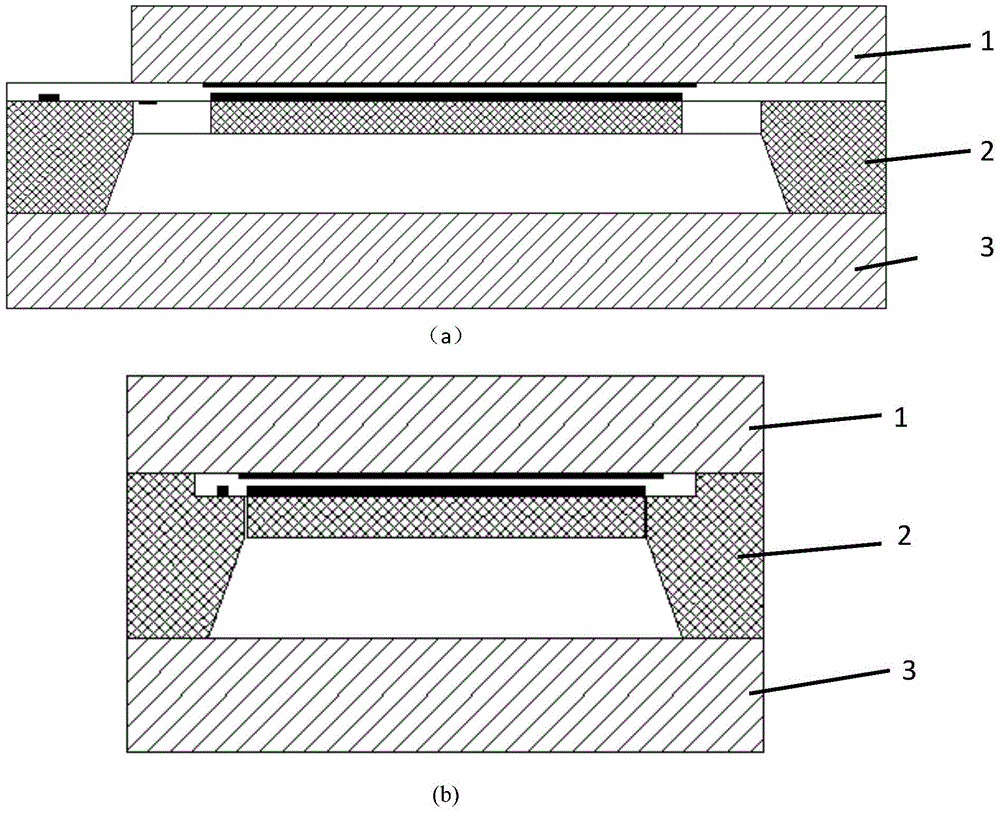

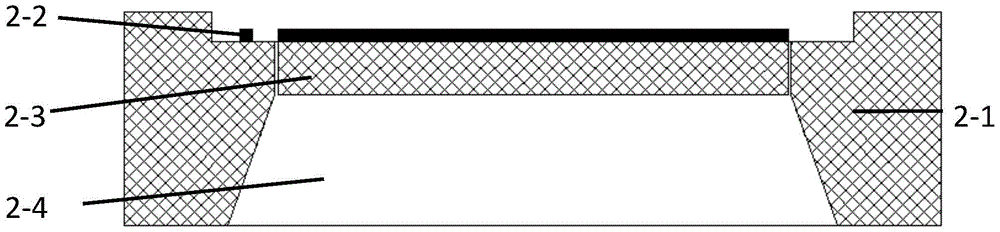

[0022] refer to figure 1 , a beam film structure high-voltage electrostatic field sensor chip based on the principle of pressure sensitivity, comprising a base 3, a silicon structure layer 2 is arranged on the base 3, an upper pole plate 1 is arranged on the silicon structure layer 2; the upper surface of the base 3 The lower surface of the silicon structure layer 2 is connected by anodic bonding, and the upper surface of the silicon structural layer 2 is connected with the lower surface of the upper plate 1 by anodic bonding.

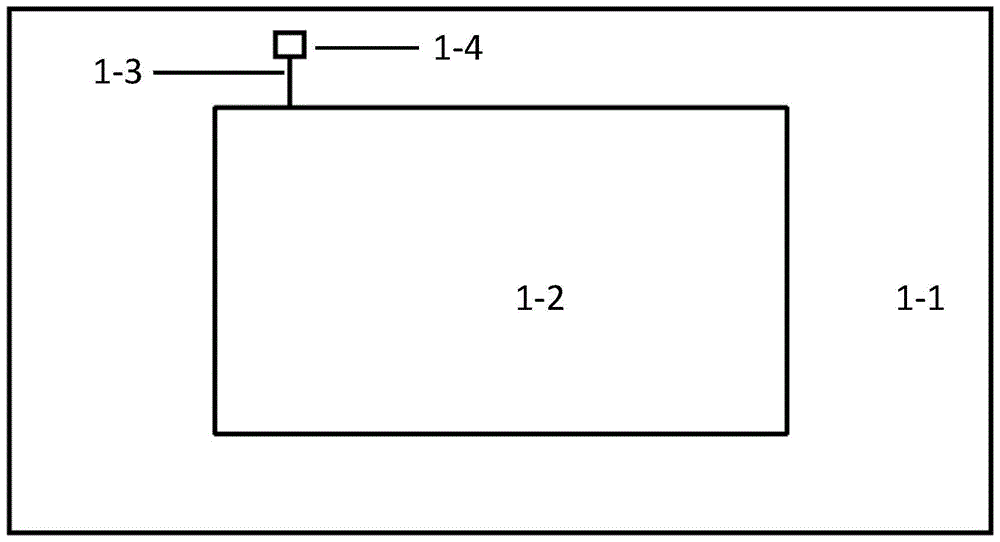

[0023] refer to figure 2 , the upper plate 1 is an electrode formed by depositing metal on the glass plate 1-1, and a rectangular fixed metal film electrode 1-2 is arranged in the middle area of the lower surface of the glass plate 1-1, and the fixed metal film electrode 1-2 is A first electrode connection pad 1-4 is arranged beside the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com