Automatic determination method of in-service tubing and casing defects based on real-time driving of well logging big data

An automatic determination and big data technology, applied in surveying, earthmoving, wellbore/well components, etc., can solve problems such as the inability to realize automatic determination of defect types, and achieve further development, high degree of automation, and good real-time performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0113] The wall thickness, inner diameter and outer diameter information of an in-service oil well casing at a depth of 2000m was measured, and the minimum wall thickness threshold of the casing made of this material is 0.220m.

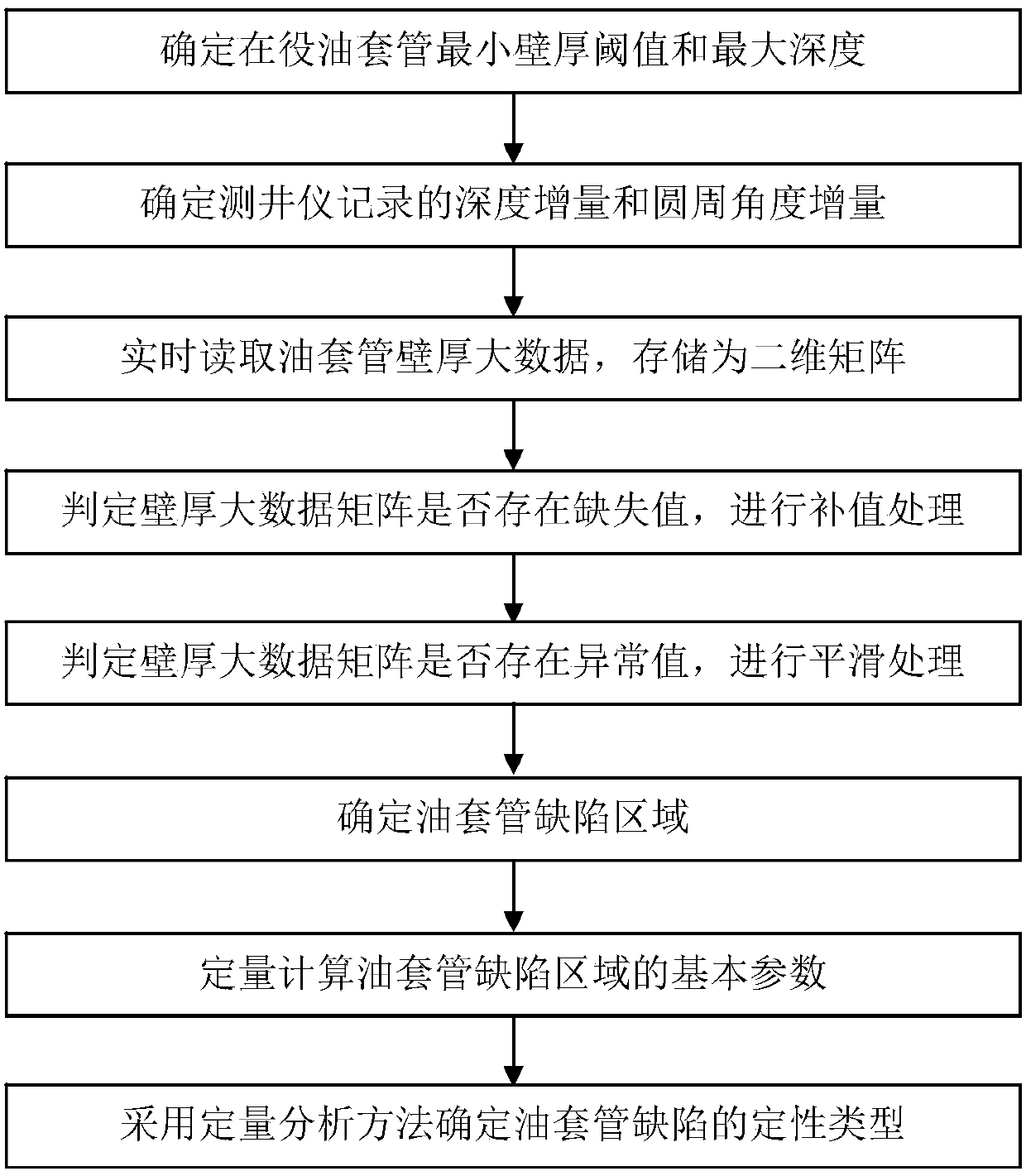

[0114] Step 1: Determine the minimum wall thickness threshold D of oil casing in service 1 = 0.22 and maximum depth H = 2000;

[0115] Step 2, determining the depth increment ΔH=0.125 and the circumferential angle increment ΔA=5° recorded by the logging tool;

[0116] Step 3: According to the condition of the logging tool, read out the big data of the wall thickness of the tubing and casing in real time, and store it as a two-dimensional matrix D; the number of rows of the wall thickness matrix N=16000, columns Number M=72;

[0117] Step 4, traverse the large data matrix D of the wall thickness of oil and casing in the order from top to bottom (i=1,2,...,N) from left to right (j=1,2,...,M), and find that in D Defaults exist at angles of 15° to 50° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com