Self-moving temporary support device beside gob-side entry retaining

A temporary support and self-moving technology, which is applied in mine roof support, mining equipment, earthwork drilling and mining, etc., can solve the problems that the support cannot be too long, the overall rigidity is small, and cannot be adapted, so as to protect the safety of operators and support Good stability, good blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

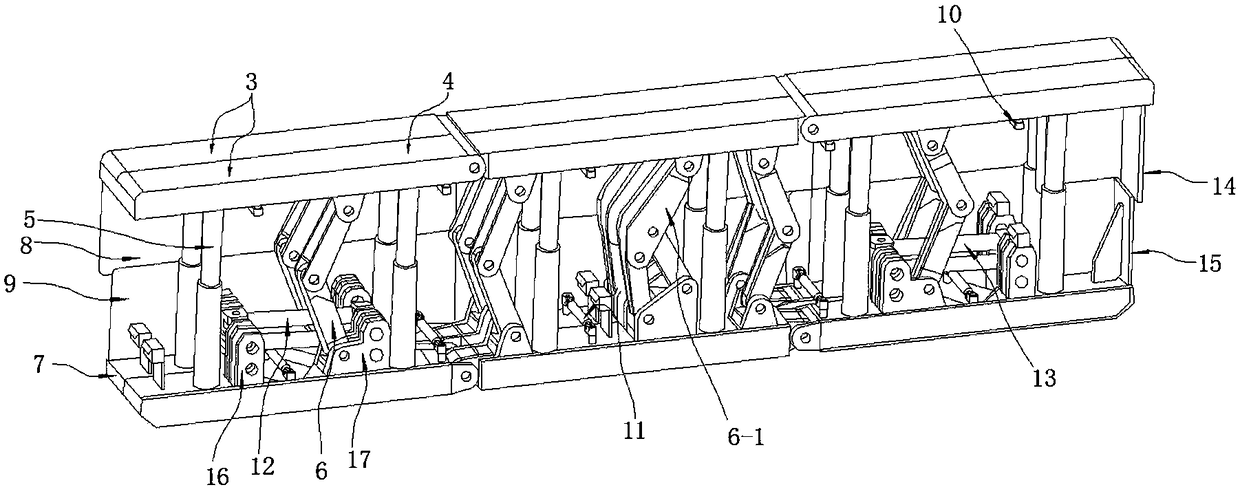

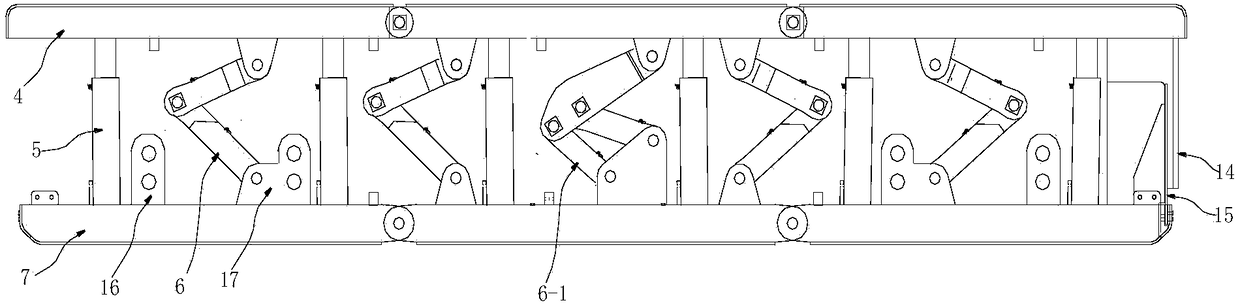

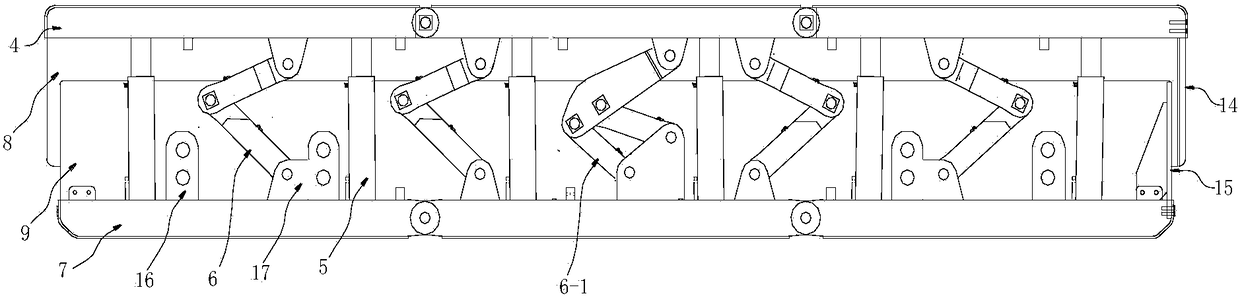

[0027] The invention provides a self-moving temporary support device beside the gob-side entry retaining, such as Figure 1 to Figure 5 As shown, the self-moving temporary support device beside the gob-side entry retaining includes an electro-hydraulic control system, and is characterized in that it includes two rows of support bodies connected side by side by oil cylinders, and the first row of support bodies 1 is close to the gob-side entryway 20 On one side, the second row of support bodies 2 is close to the side of the gob. Each row of support bodies includes three support units 3 connected in sequence. Each support unit 3 includes a top beam 4, and the top beam 4 passes through a hydraulic column 5 and a single pendulum The rod 6 is connected to the base 7, wherein the second row of bracket units 3 of each row of bracket bodies is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com