Method and device for controlling piston cooling system

A piston cooling and cooling system technology, applied in liquid cooling, engine cooling, engine components, etc., can solve problems such as unreasonable injection, achieve precise control, save emissions and fuel consumption, and increase warm-up speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings. It is only intended to describe the specific implementation of the present invention in detail, and does not impose any limitation on the present invention, and the scope of protection of the present invention shall be determined by the claims.

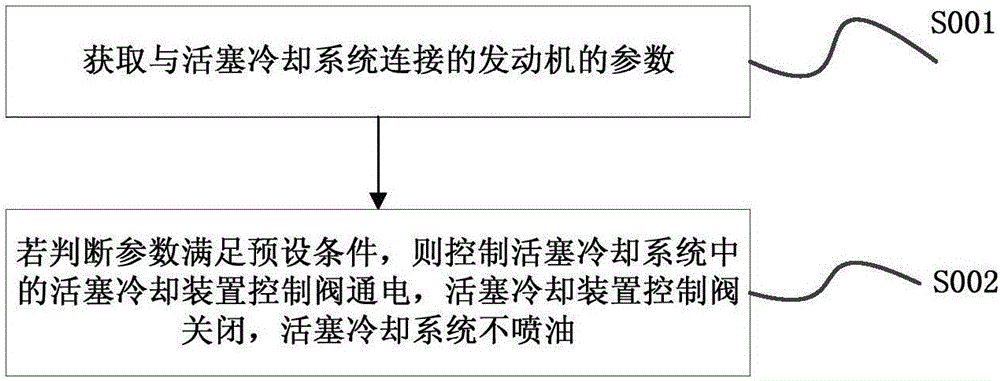

[0034] refer to figure 1 , the present invention proposes a method for controlling a piston cooling system, comprising:

[0035] The obtaining step S001 includes: obtaining parameters of the engine connected to the piston cooling system;

[0036] The judging step S002 includes: if the judging parameter satisfies the preset condition, then controlling the control valve of the piston cooling device in the piston cooling system to be energized, the control valve of the piston cooling device to be closed, and the piston cooling system not to spray oil.

[0037] In the obtaining step S001, first obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com