Static-pressure spindle

A static pressure spindle and rotating shaft technology, applied in the direction of bearings, shafts and bearings, mechanical equipment, etc., can solve the problems of precision and stiffness, and cannot promote thrust bearings, etc., to achieve large radial bearing capacity, uniform heating temperature distribution, The effect of little wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

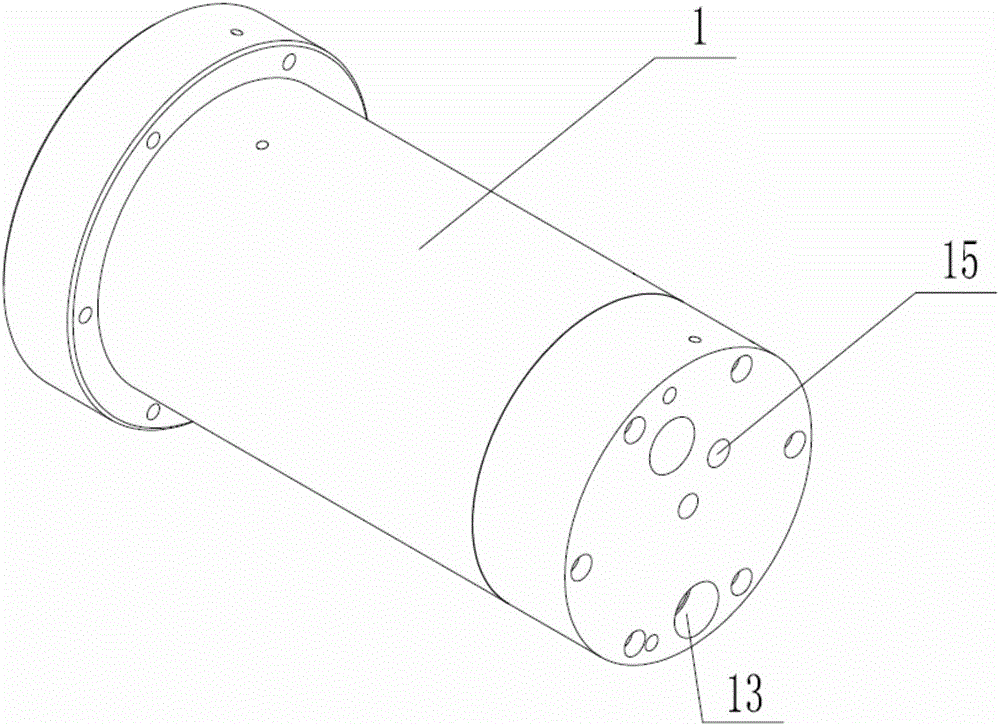

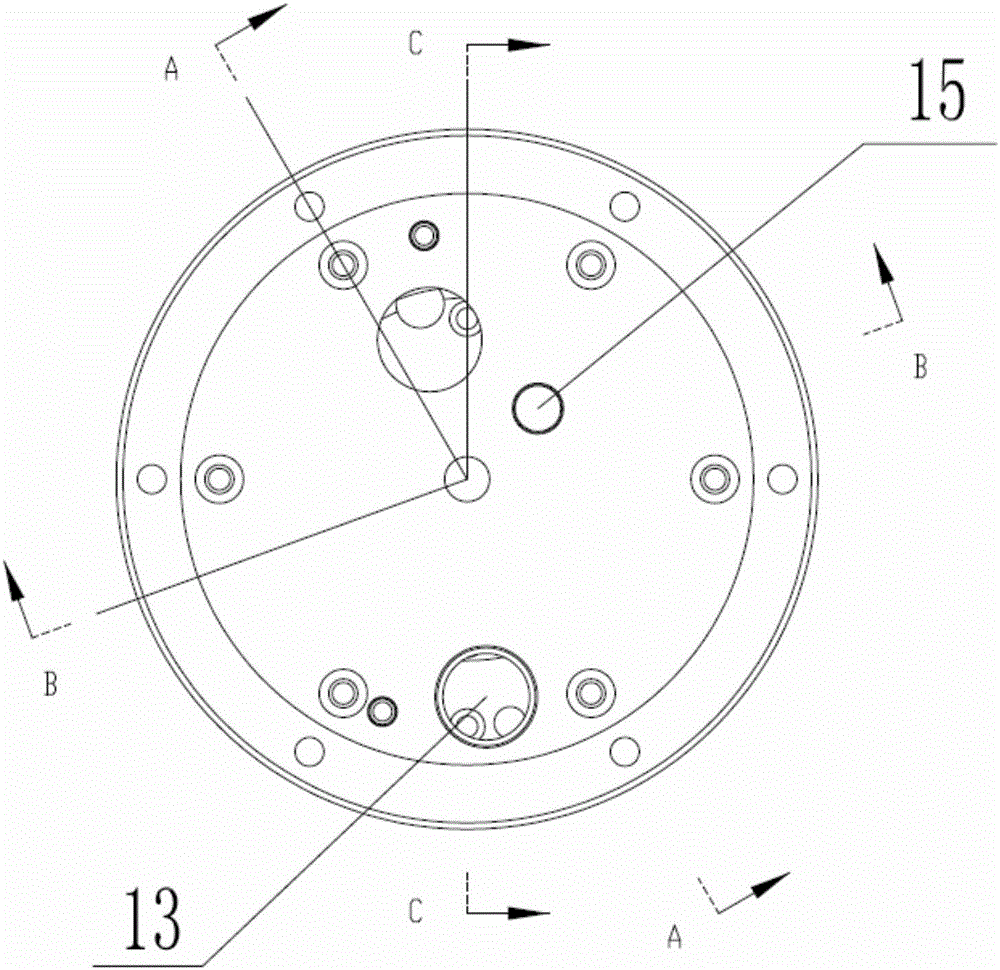

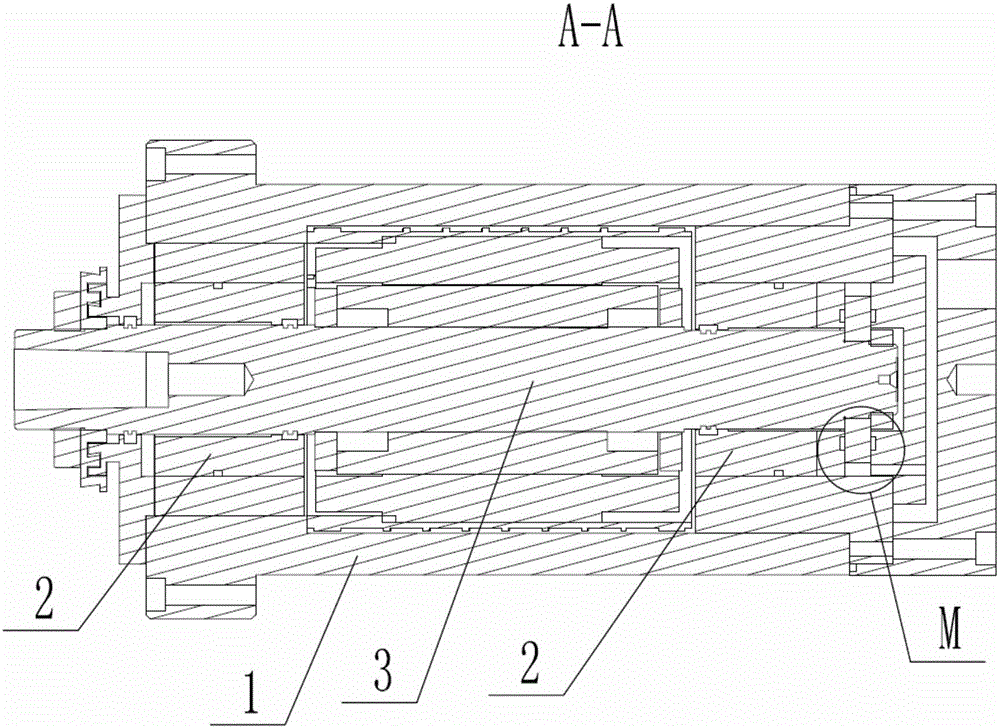

[0032] The present invention provides a static pressure spindle, which includes a housing 1 and a rotating shaft 3 that is rotatably fitted in the housing 1 through a radial bearing 2. The housing 1 is provided with a thrust bearing for restricting the movement of the rotating shaft 3 in the axial direction. It is characterized in that the thrust bearing includes a first subcomponent 5 and a second subcomponent 6 that exert an axial balance force on the shoulder 4 of the rotating shaft 3, and the first subcomponent 5 and the second subcomponent 6 are near the shoulder The end faces of 4 are respectively provided with working oil grooves 7, and each working oil groove 7 cooperates with the end surface of the corresponding shoulder 4 to form a main oil chamber, and the first sub-component 5 and the second sub-component 6 are respectively provided ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap