Sound wave leakage positioning method based on same-side sensor arrangement

A positioning method and sensor technology, which can be used in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., and can solve problems such as long response time, low safety, and increased danger.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

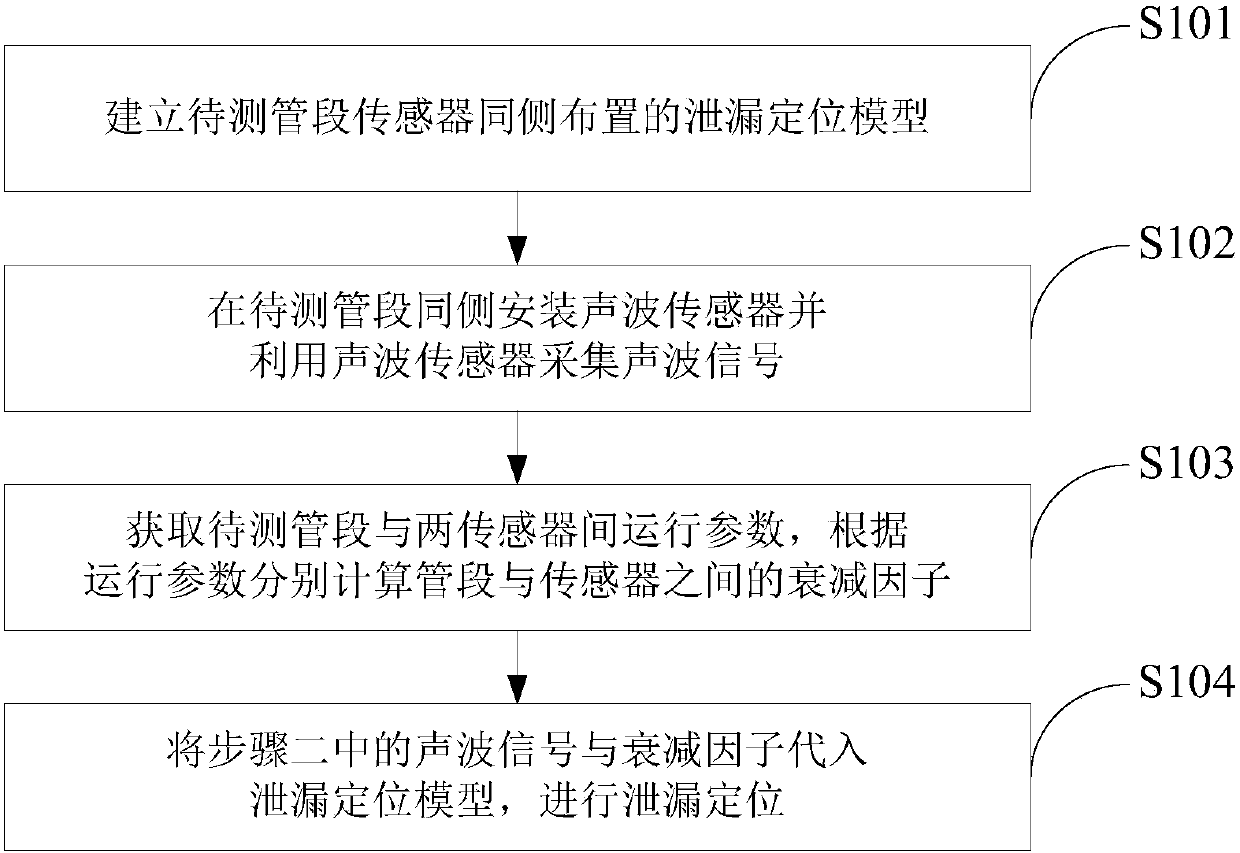

[0035] Such as figure 1 As shown, the acoustic leakage localization method based on the sensor arrangement on the same side includes the following steps:

[0036] Step S101: Establish a leak location model with sensors arranged on the same side of the pipe section to be tested;

[0037] Step S102: installing an acoustic wave sensor on the same side of the pipe section to be tested and using the acoustic wave sensor to collect acoustic signals;

[0038] Step S103: Obtain the operating parameters between the pipe section to be tested and the two sensors, and calculate the attenuation factors between the pipe section and the sensors according to the operating parameters;

[0039] Step S104: Substitute the acoustic wave signal and attenuation factor in step 2 into the leak location model to perform leak location.

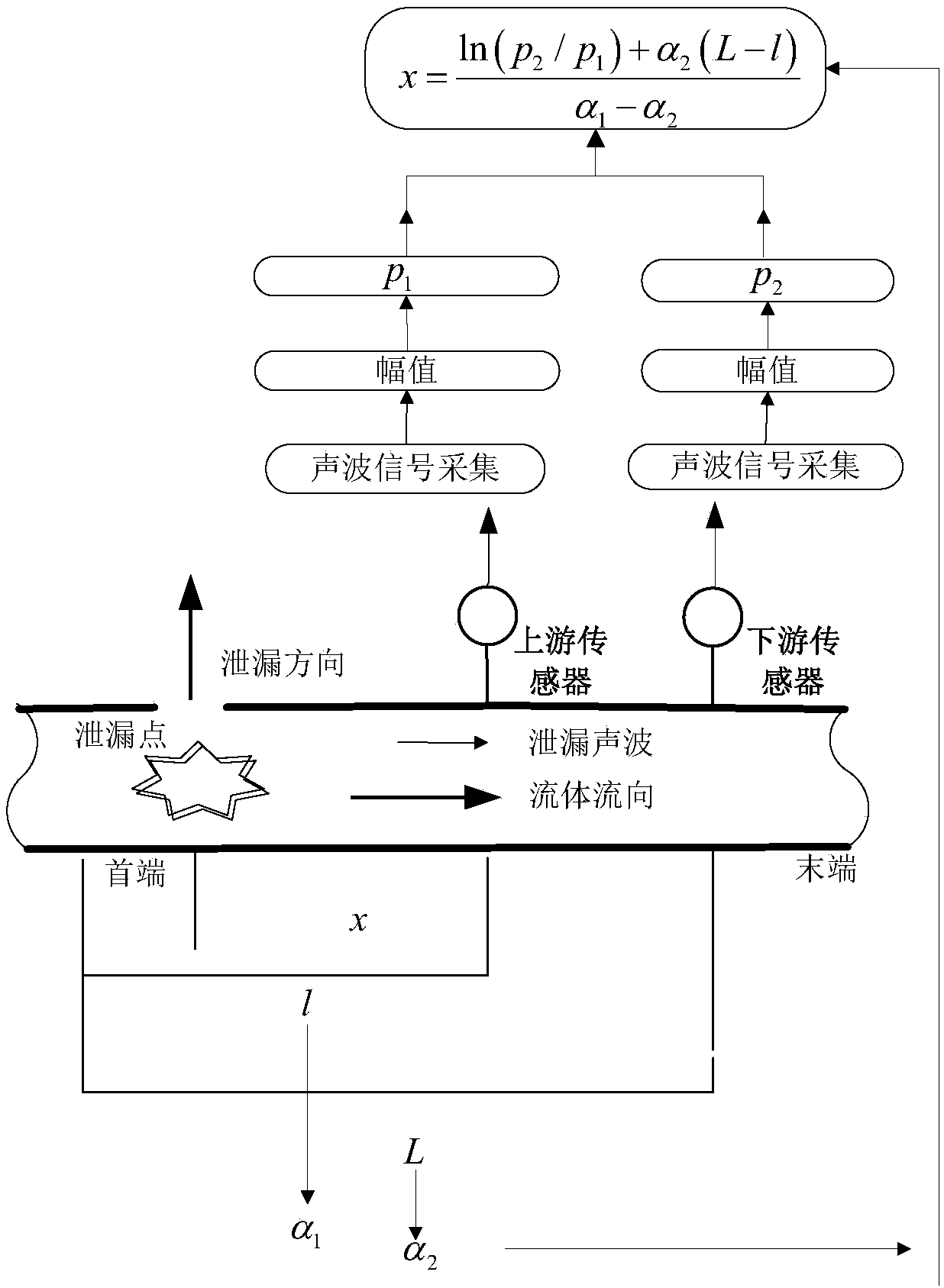

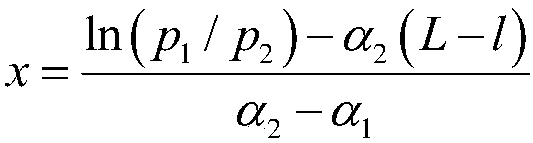

[0040] Such as figure 2 As shown, bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com