Device and method for on-site accurate testing of heat conductivity of energy-saving thermal insulation materials

A thermal insulation material and thermal conductivity technology, which is applied in the field of thermal characteristic testing of energy-saving thermal insulation materials, can solve the problem of affecting the measurement accuracy, inability to realize on-site in-situ testing of energy-saving and thermal insulation materials, and inability of detectors to achieve on-site in-situ testing, etc. problem, to achieve the effect of ensuring accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0039] The invention provides a device and method for accurately testing the thermal conductivity of an energy-saving and heat-insulating material on site.

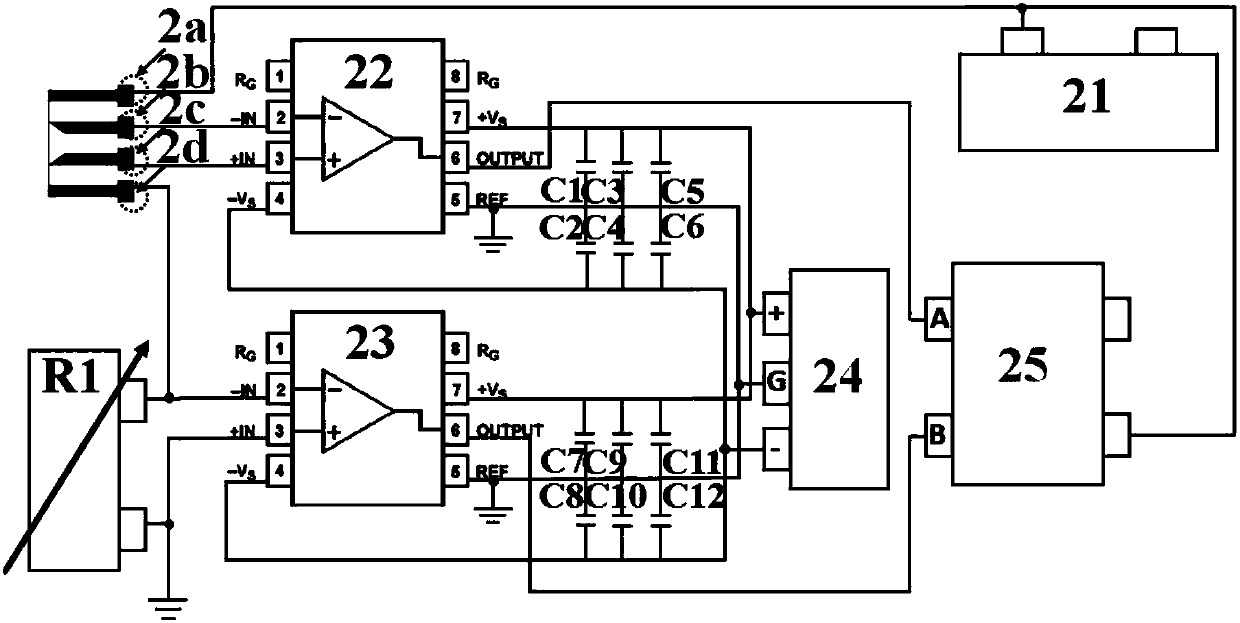

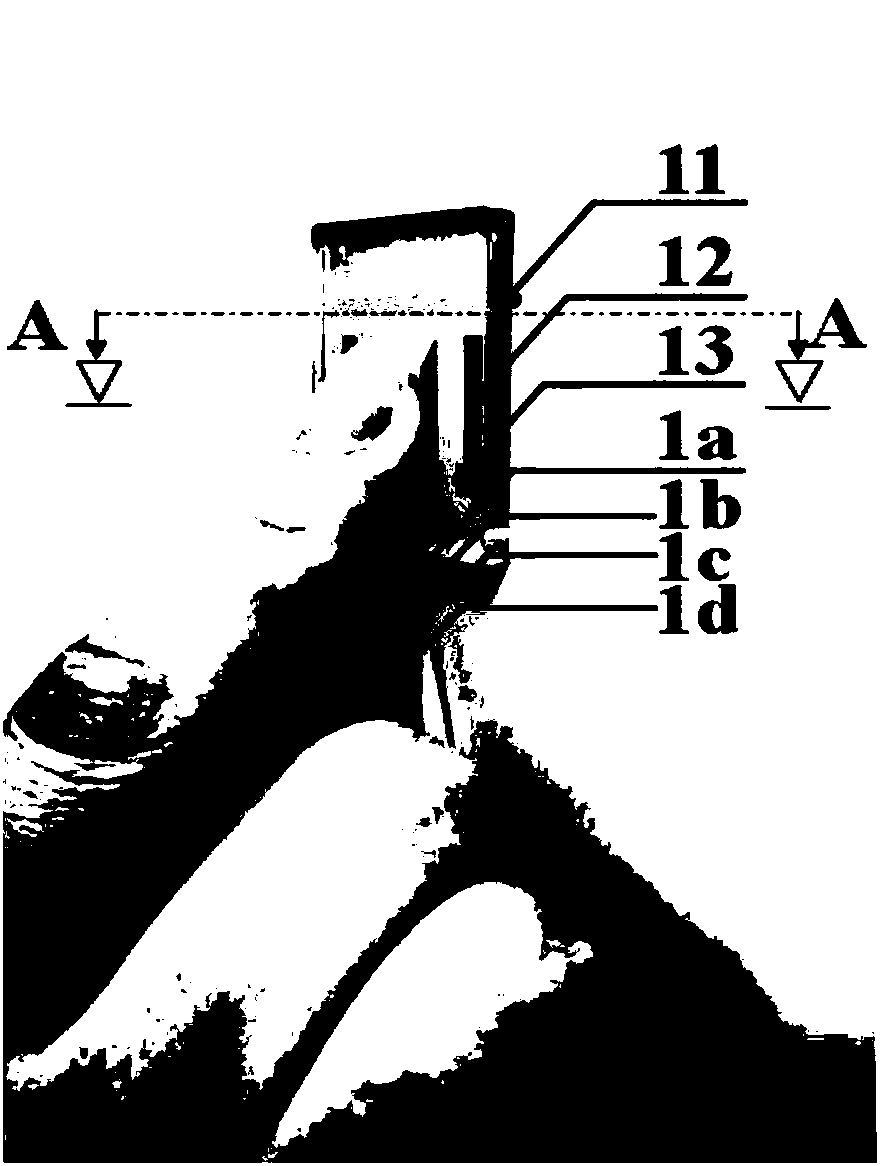

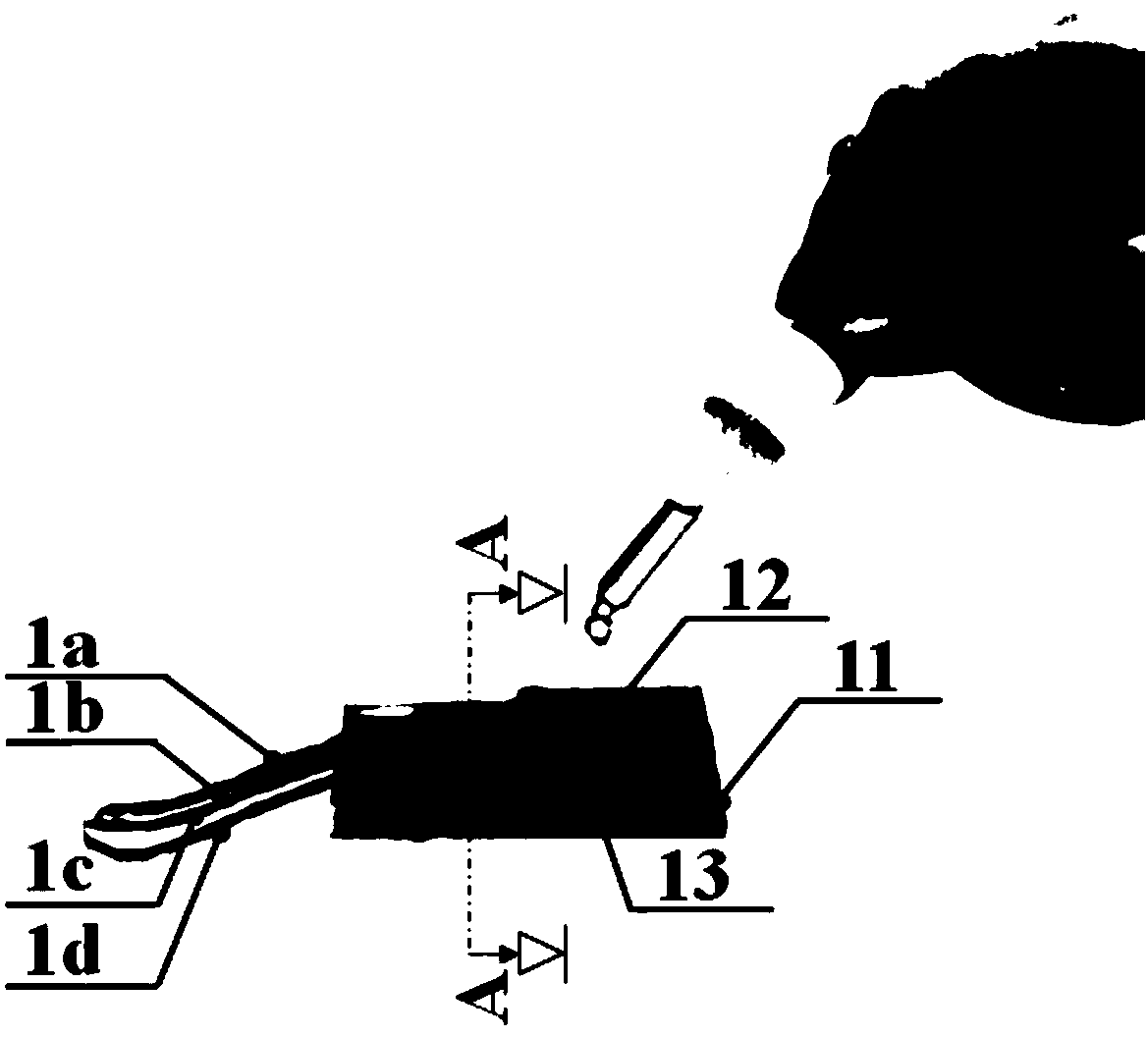

[0040] Firstly, the invention provides a device for accurately testing the thermal conductivity of energy-saving and heat-insulating materials on site. figure 1 It is a schematic diagram of an on-site test device for thermal conductivity of energy-saving and heat-insulating materials according to an embodiment of the present invention. figure 2 for figure 1 Schematic diagram of the structure of the self-adaptive thermal response detector in the test setup shown. image 3 for figure 1 The operation diagram of the self-adaptive thermal response detector for testing liquid or powder energy-saving a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com