Improved structure of stator iron core

A stator core and improved structure technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit static parts, etc., can solve the problems of low work efficiency, unavailable winding method, high production cost, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

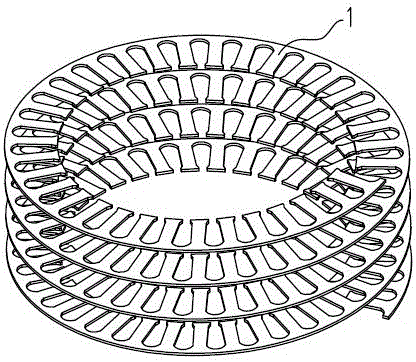

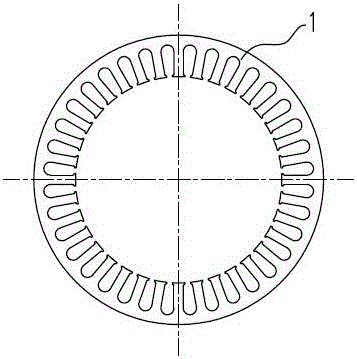

[0025] Such as Figure 11-12 As shown, the stator core is divided into a trough-shaped part body 1 and a yoke part body 2. The above two parts are respectively wound into a helical circle by a winding method and then arranged and formed. The formed yoke part body 2 is sleeved in the groove The outer ring of the shaped part body 1 is integrated to form a whole iron core.

[0026] Such as Figure 2-4 As shown, the trough part body 1 of the present invention is axially wound into a circular and spiral loose semi-finished product with a predetermined number of turns, and then through the first finishing, welding, rivets or self-fastening are used to sort it into an integrated form.

[0027] Such as Figure 5-7 As shown, the body 2 of the yoke portion of the present invention is axially wound into a circular and spiral loose semi-finished product with a predetermined num...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com