Conductive laminate, method of manufacturing conductive laminate, touch panel, and touch switch

A technology of conductive laminates and manufacturing methods, which is applied in the direction of cable/conductor manufacturing, conductive layers on insulating carriers, carbon-silicon compound conductors, etc., can solve the problems of reducing the conductivity of conductive laminates, and achieve transparent conductivity and humidity resistance Excellent effect of dependence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0123] The preparation method of the CNT dispersion liquid used in the present invention is not particularly limited, for example, it can be carried out in the following steps. Since the processing time at the time of dispersion can be shortened, it is preferable to prepare a dispersion containing CNT in a concentration range of 0.003 to 0.15% by mass in a dispersion medium, and then dilute it to a predetermined concentration. In the present invention, the mass ratio of the dispersion medium to the CNT (that is, the mass of the dispersion medium when the mass of the CNT is 1) is preferably 10 or less. If it is the above-mentioned preferable range, it will be easy to disperse uniformly, and on the other hand, there will be little influence of electroconductivity fall. The mass ratio of the dispersion medium to CNT is more preferably 0.5-9, still more preferably 1-6, particularly preferably 2-3.

[0124] As the dispersion means when preparing the CNT dispersion liquid, the use ...

Embodiment

[0186] Hereinafter, based on an Example, the manufacturing method of the electroconductive laminated body of this invention and the electroconductive laminated body of this invention is demonstrated concretely. However, the present invention is not limited to the following examples.

[0187]

[0188] (1) Light absorbance of the conductive laminate

[0189] About the electroconductive laminated body which sampled 5 cm x 10 cm, it measured using the ultraviolet-visible-infrared spectrophotometer UV-3150 by Shimadzu Corporation. Light was incident vertically from the side of the conductive laminate on which the conductive layer was formed, the total light transmittance and relative reflectance at 550 nm were measured, and the absorbance was calculated using the following formula to obtain the absorbance of the conductive laminate.

[0190] Absorbance (550nm) = 100 - total light transmittance (550nm) - relative reflectance (550nm).

[0191] (2) Surface resistance value of cond...

manufacture example

[0268] (2) CNT aggregate production example: Synthesis of CNT aggregates

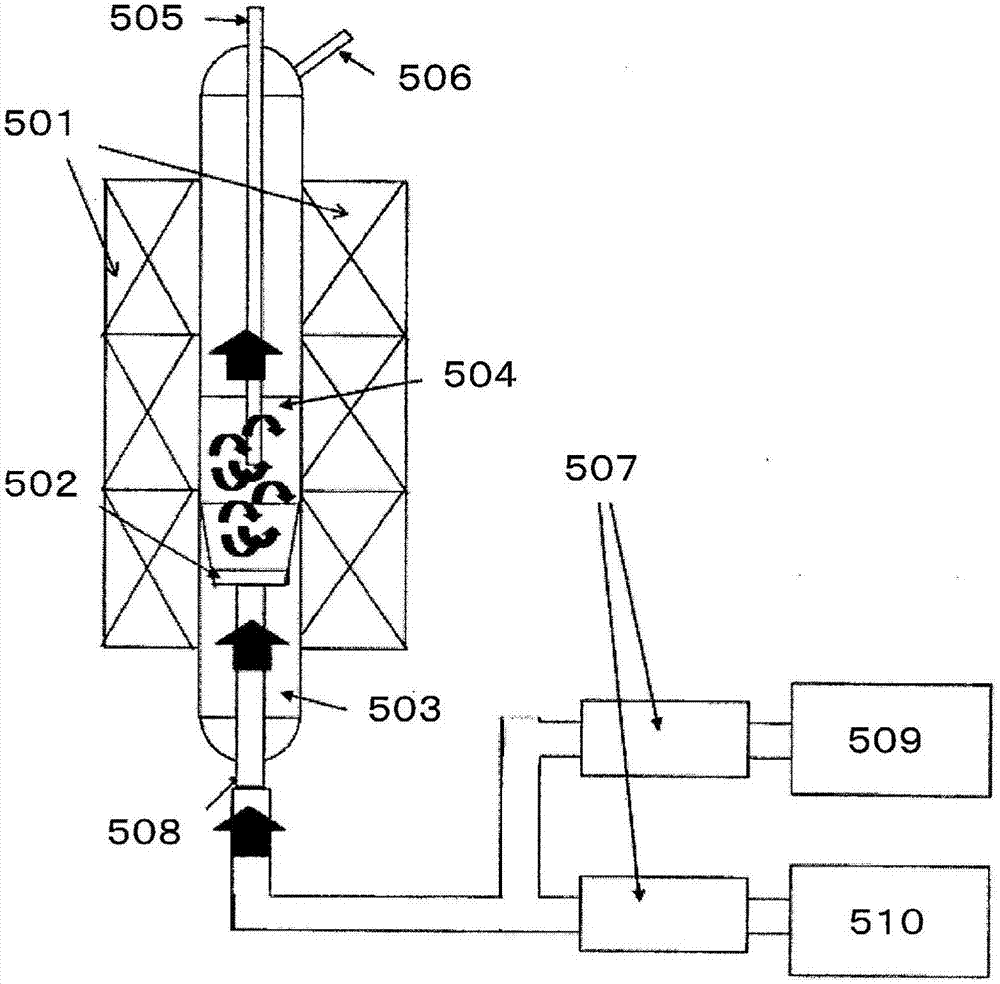

[0269] use figure 1 The shown setup performs the synthesis of CNTs. The reactor 503 is a cylindrical quartz tube with an inner diameter of 75 mm and a length of 1,100 mm. A quartz sintered plate 502 is provided in the center, a mixed gas introduction pipe 508 serving as an inert gas and source gas supply line is provided in the lower part of the quartz tube, and an exhaust gas pipe 506 is provided in the upper part. Furthermore, three electric furnaces 501 are provided as heaters surrounding the circumference of the reactor so that the reactor can be kept at an arbitrary temperature. In addition, a thermocouple 505 is provided to detect the temperature in the reaction tube.

[0270] The catalyst layer 504 was formed by weighing 132 g of the solid catalyst prepared in the catalyst preparation example and introducing it onto the quartz sintered plate at the center of the reactor arranged in the vertica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com