Circulating water aquaculture system

A technology of circulating aquaculture and water inlet pipes, which is applied in fish farming, soilless cultivation, animal husbandry, etc., can solve the problems of poor improvement of water body, influence of aquatic product output, poor bait dispersion, etc., and achieve structural Simple, good anti-rust effect, avoid waste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

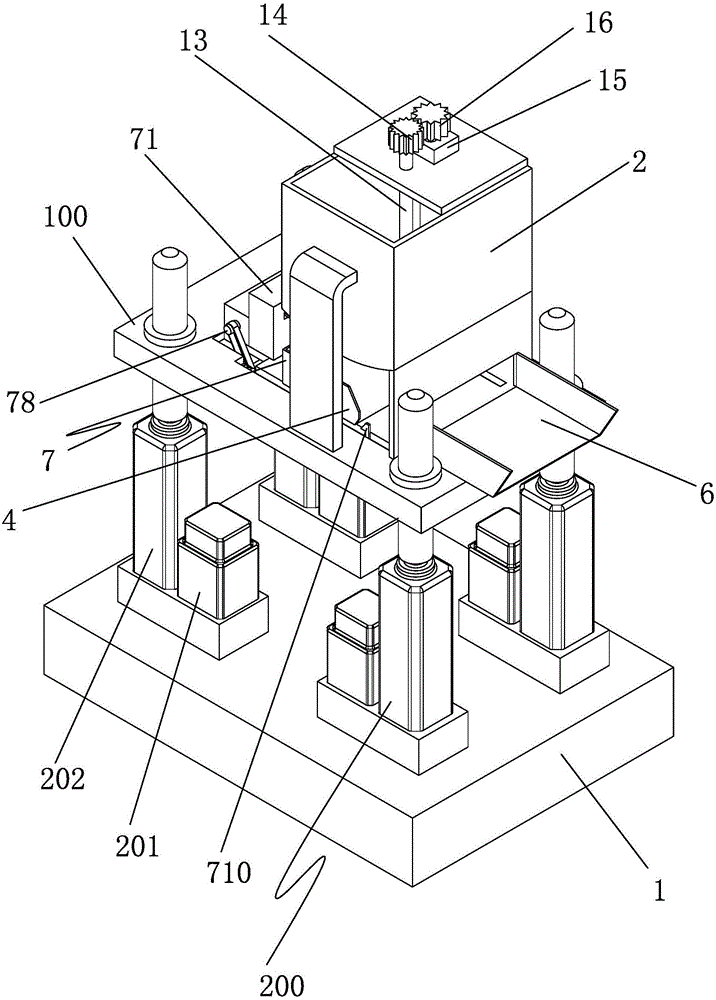

[0046] In the first embodiment of the lifting mechanism 200 in the present invention, the lifting mechanism 200 includes an electric cylinder 201 arranged on the floating platform 1, and the four electric cylinders 201 are respectively arranged under the four corners of the installation platform 100, The screw shaft 202 of the electric cylinder 201 is connected with the installation platform 100 .

[0047] In the second embodiment of the lifting mechanism 200 in the present invention, the lifting mechanism 200 includes four cylinders arranged on the floating platform 1, and the four cylinders are respectively arranged under the four corners of the installation platform 100. The cylinder shaft of the air cylinder is connected with the mounting platform 100 .

[0048] The invention is provided with a dial mechanism, which can effectively ensure the smooth feeding of materials in the storage tank. In the present invention, the ejection device can eject the materials in the feedi...

Embodiment 4

[0076] Example 4 - Corrosion Resistant Coating

[0077] Corrosion-resistant coatings include the following components by weight percentage:

[0078]

[0079] Preparation method: Mix fluorinated acrylate and coal tar pitch evenly, stir and heat to 45°C, stir for 10 minutes, add nepheline powder and zinc citrate, heat to 120°C, stir for 3 hours, cool to 50°C, add other components , stirred and kept for 1 hour, ultrasonically dispersed for 10 minutes, and ground to a fineness of <60 μm in a conical grinder.

Embodiment 5

[0080] Example 5 - Corrosion Resistant Coating

[0081] Corrosion-resistant coatings include the following components by weight percentage:

[0082]

[0083]

[0084]Preparation method: Mix fluorinated acrylate and coal tar pitch evenly, stir and heat to 60°C, stir for 60 minutes, add nepheline powder and zinc citrate, heat to 145°C, stir for 5 hours, cool to 60°C, add other components , stirred and kept for 2 hours, ultrasonically dispersed for 25 minutes, and ground to a fineness of <60 μm in a conical grinder.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com