Controls for grain preparation equipment

A control device and grain technology, applied in grain processing, agriculture, application, etc., can solve the problems of not being able to know the abnormal occurrence status and maintenance status, time spent, fault recovery time and long repair time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] Embodiments of the present invention will be described with reference to the drawings. In addition, the present invention is not limited by these embodiments, and the present invention can be implemented in various forms without changing the gist of the invention.

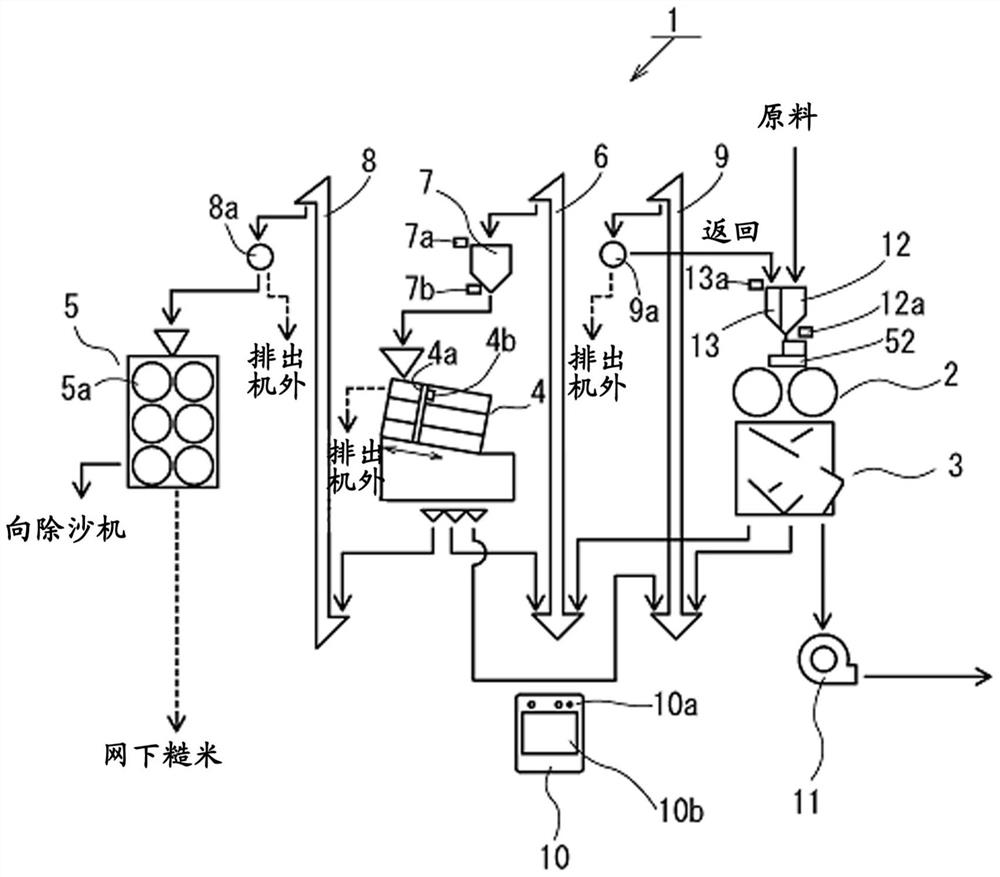

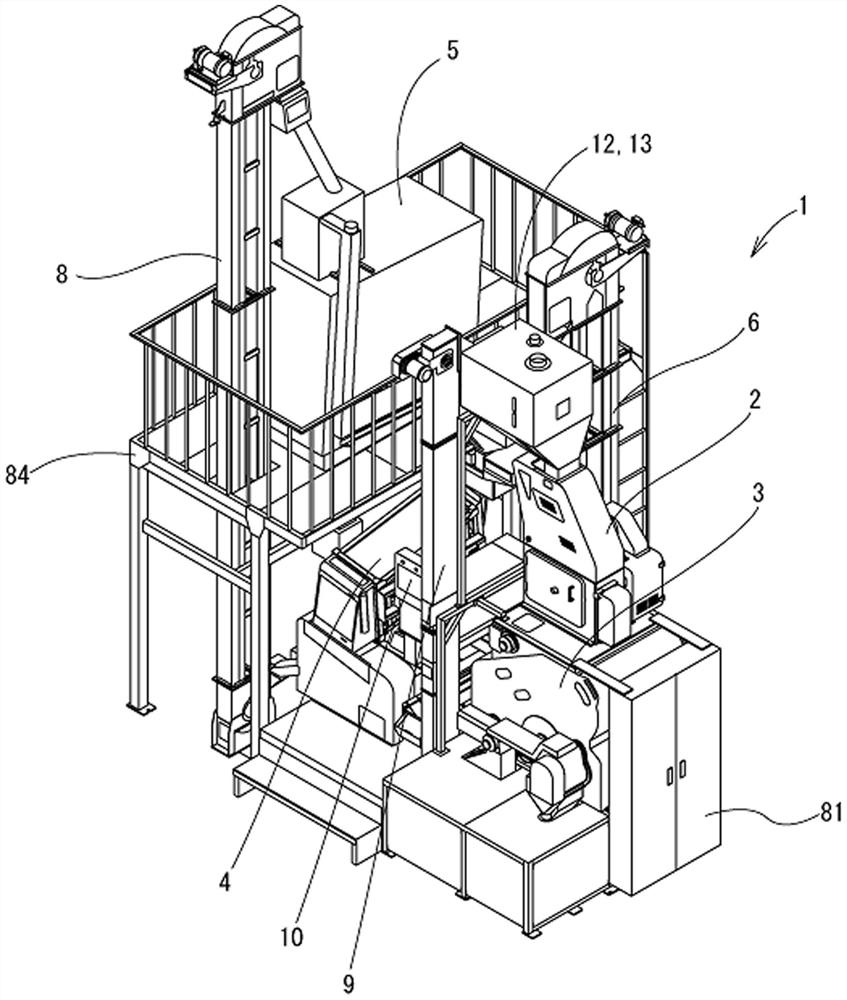

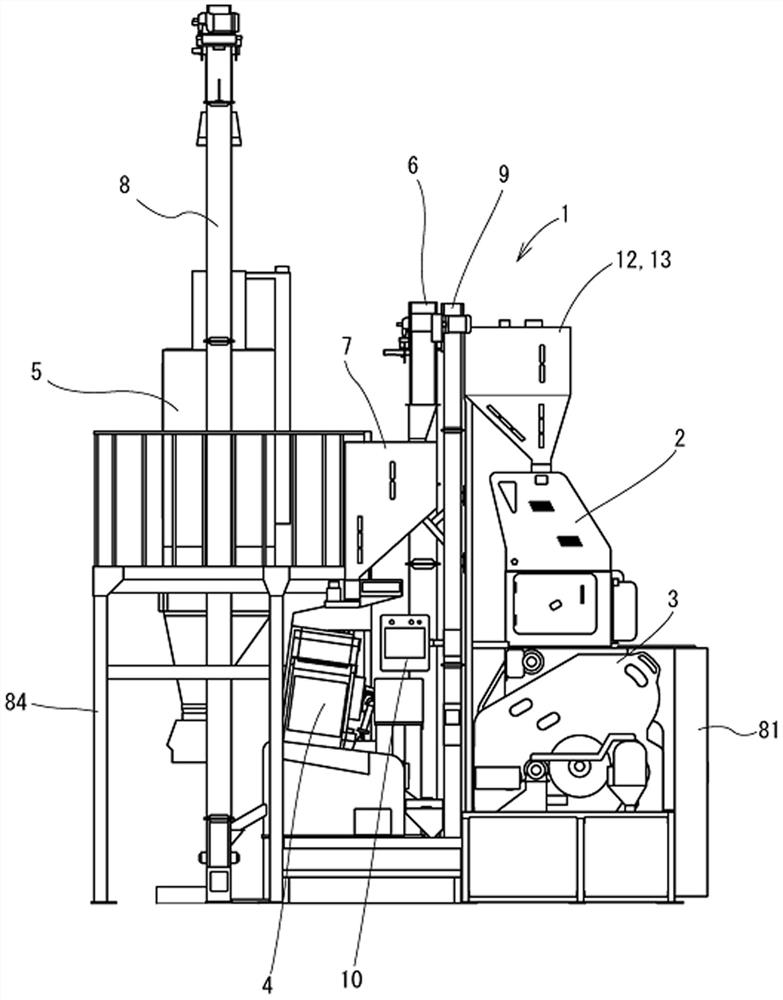

[0037] Embodiments of the present invention will be described with reference to the drawings. figure 1 is a flowchart showing the processing procedure of the grain preparation equipment of the present invention, figure 2 is a perspective view showing the overall appearance of the grain preparation facility, image 3 is its front view.

[0038] Such as Figure 1 to Figure 3 As shown, the grain preparation equipment 1 of the present invention has the following parts as main parts: a paddy hulling section 2 composed of a pair of rubber rollers; Sorted winnowing part 3; the shaking sorting part 4 that separates the mixed rice after wind sorting into paddy, brown rice and mixed rice by shaking and sorting ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com