Quality analysis device and quality analysis method

A quality analysis and quality technology, applied in the direction of comprehensive factory control, program control, electrical program control, etc., can solve problems such as ambiguity, and achieve the effect of easy bad conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

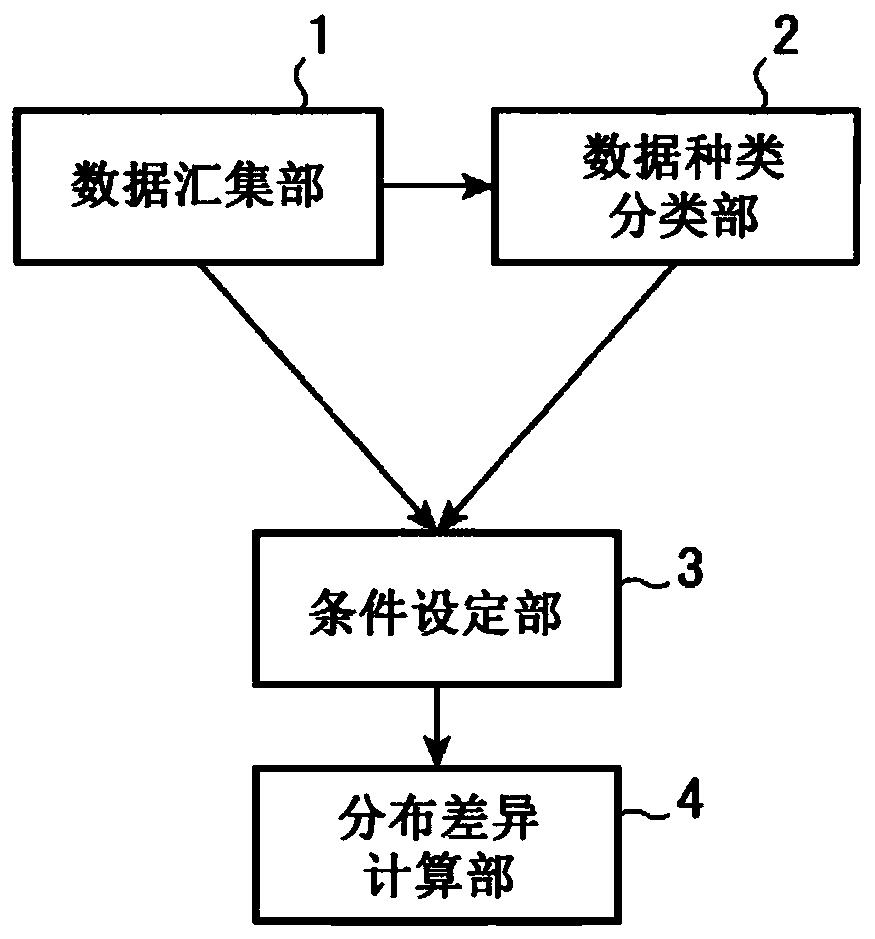

[0029] figure 1 It is a configuration diagram of the quality analyzer according to the present embodiment.

[0030] The quality analysis device according to this embodiment includes a data collection unit 1 , a data type classification unit 2 , a condition setting unit 3 , and a distribution difference calculation unit 4 . The data collection unit 1 is a processing unit that acquires quality data and device information data. The data type classification unit 2 is a processing unit that classifies the quality data and device information data acquired by the data collection unit 1 according to a set predetermined rule. The condition setting unit 3 is for the data acquired by the data collection unit 1 or the data classified by the data type classification unit 2, for the data items to be aggregated, the reference conditions representing the basic conditions for quality analysis, and the standard conditions representing the quality analysis. A processing unit that sets comparis...

Embodiment approach 2

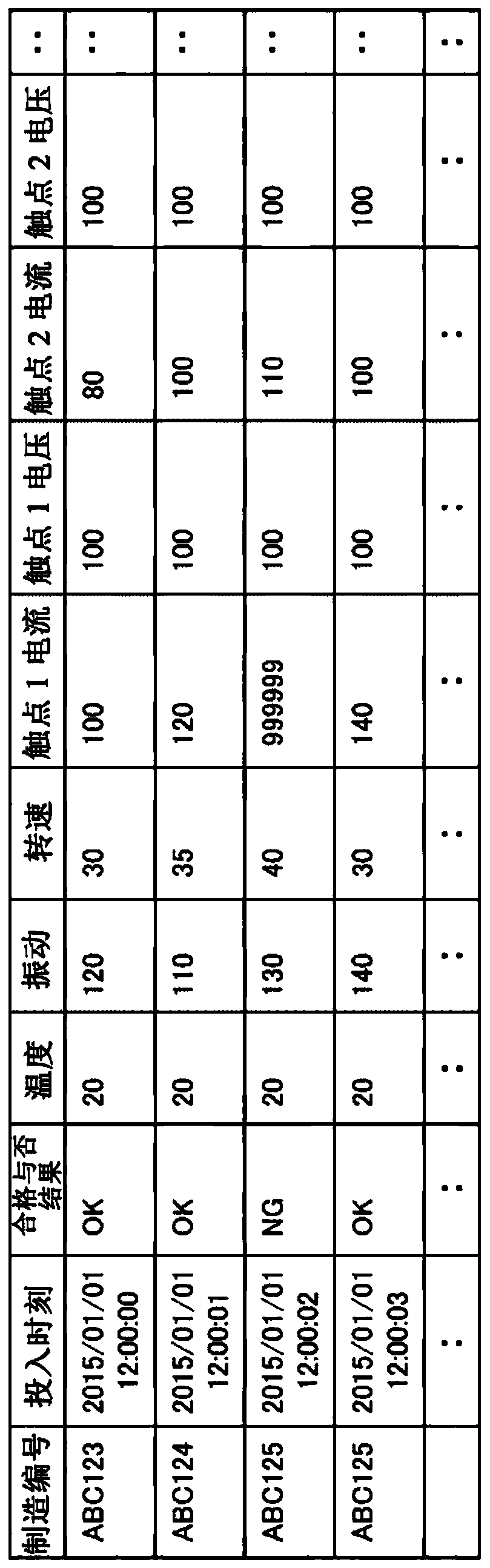

[0079] In Embodiment 2, event data is also included as the data obtained by the data collection unit 1, and the relationship between the value of the data item obtained in Embodiment 1 and the event data is obtained, wherein the event data represents , about the device, what kind of event happened.

[0080] That is, the data item with a high degree of deviation between the reference condition and the comparison condition extracted by the distribution difference calculation unit 4 is only a phenomenon that is statistically obtained from the quality data and the device information data and has a high possibility of failure ( Hereinafter, these are referred to as factor candidates). Therefore, in the second embodiment, the event data confirmed by experts in the past is correlated with the value obtained by collecting the change of OK / NG of the factor candidate and the statistic. Accordingly, it is possible to obtain a result equivalent to a result reflecting an expert's opinion....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com