Heating structure of scraper mechanism of compounding machine

A technology of heating structure and compound machine, which is applied in the direction of coating, liquid coating device on the surface, etc. It can solve the problems of uneven heating, glue seepage, and uneven coating of hot melt adhesive on the surface of the cutter body and rubber baffle. , to achieve the effect of diversification of heating methods, meeting production needs, and good heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

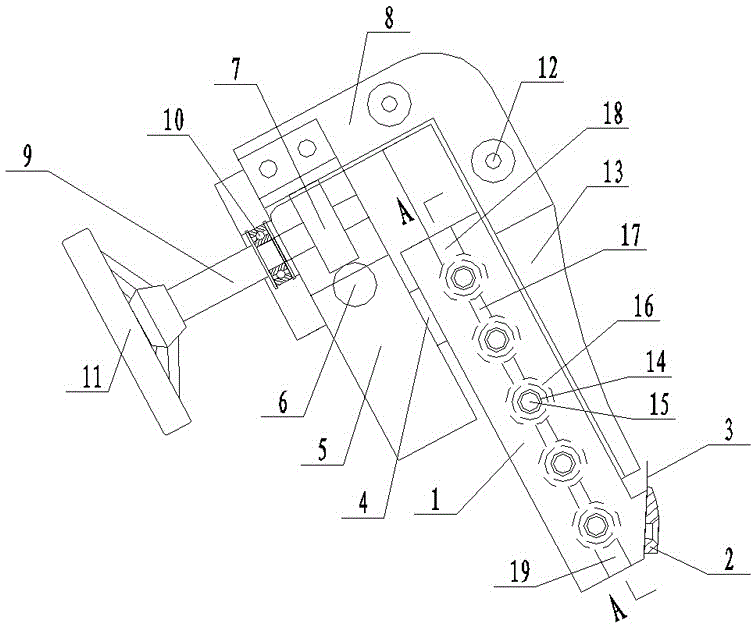

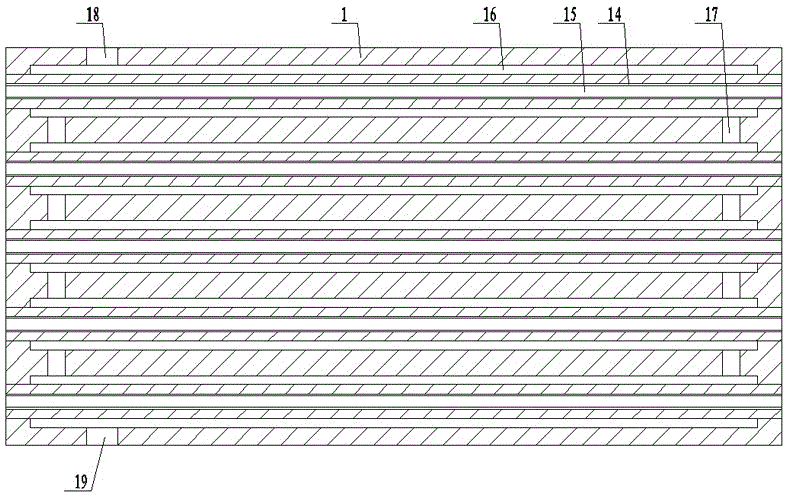

[0010] like figure 1 , figure 2 As shown, the heating structure of the composite machine blade mechanism includes: a steel plate cutter body 1, a blade 3 is fixedly arranged at the lower end of the steel plate cutter body 1 through a pressure knife plate 2, and a pin is passed at the upper end of the steel plate cutter body 1 4 is connected with a rack and pinion plate 5, and a rack 6 and a gear 7 cooperating with the rack 6 are arranged in the rack and pinion plate 5, and the upper end of the steel plate cutter body 1 and the rack and pinion plate 5 is arranged There is a sliding steel frame 8, and the connecting rod 9 is arranged in the sliding steel frame 8 through the bearing seat 10. One end of the connecting rod 9 extends into the rack and pinion plate 5 and is connected with the gear 7. The other end of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com