Electronic component detection method and device

An electronic component and detection method technology, which is applied in the field of electronic component detection and device, can solve the problems of high cost, time-consuming assembly cost, complexity, etc., and achieve the effects of being less prone to failure, saving costs, and simplifying space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

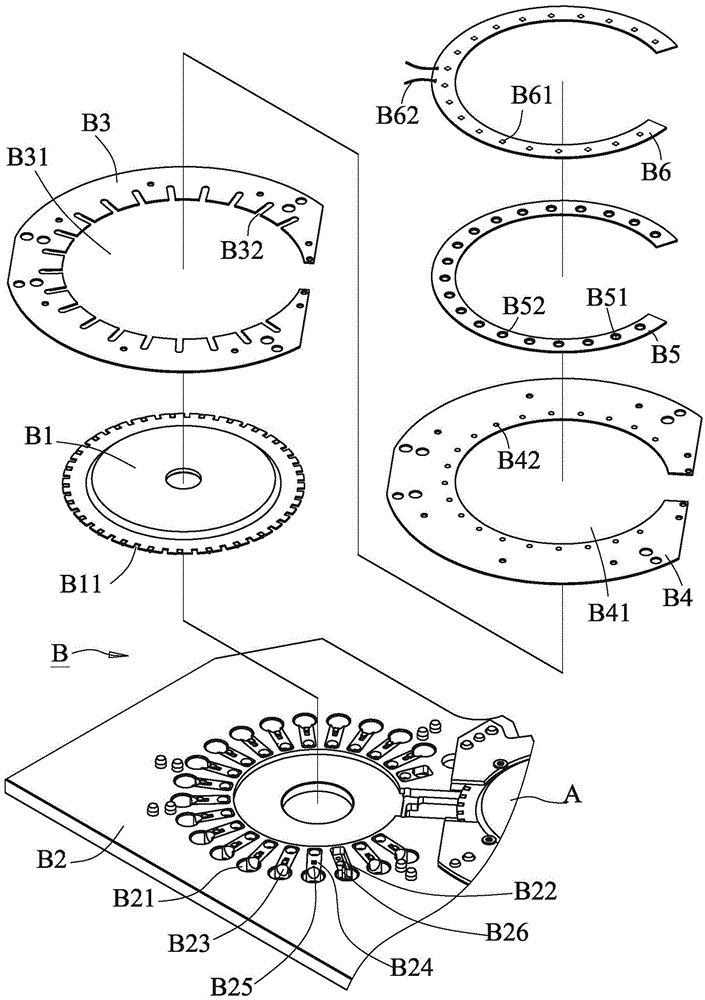

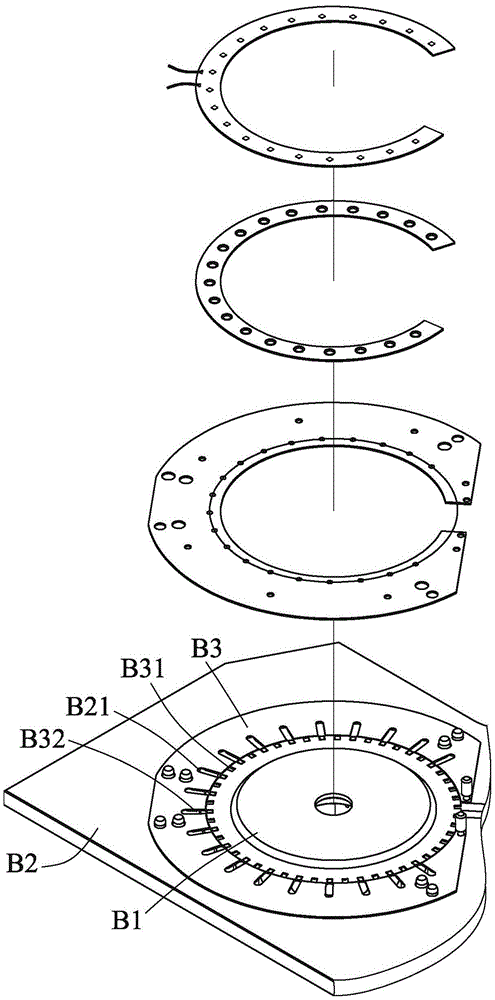

[0039] see figure 1 , 2 , the electronic component testing method and device of the embodiment of the present invention uses the test plate A as shown in the figure to carry the test component intermittently in the rotating flow path. After going through the procedures of multiple testing stations, according to the detected physical characteristics, It is illustrated by the classification mechanism B of the turntable B1 similar to the aforementioned measuring disk A, which has a circumferential arrangement of equally spaced concave loading slots B11, wherein:

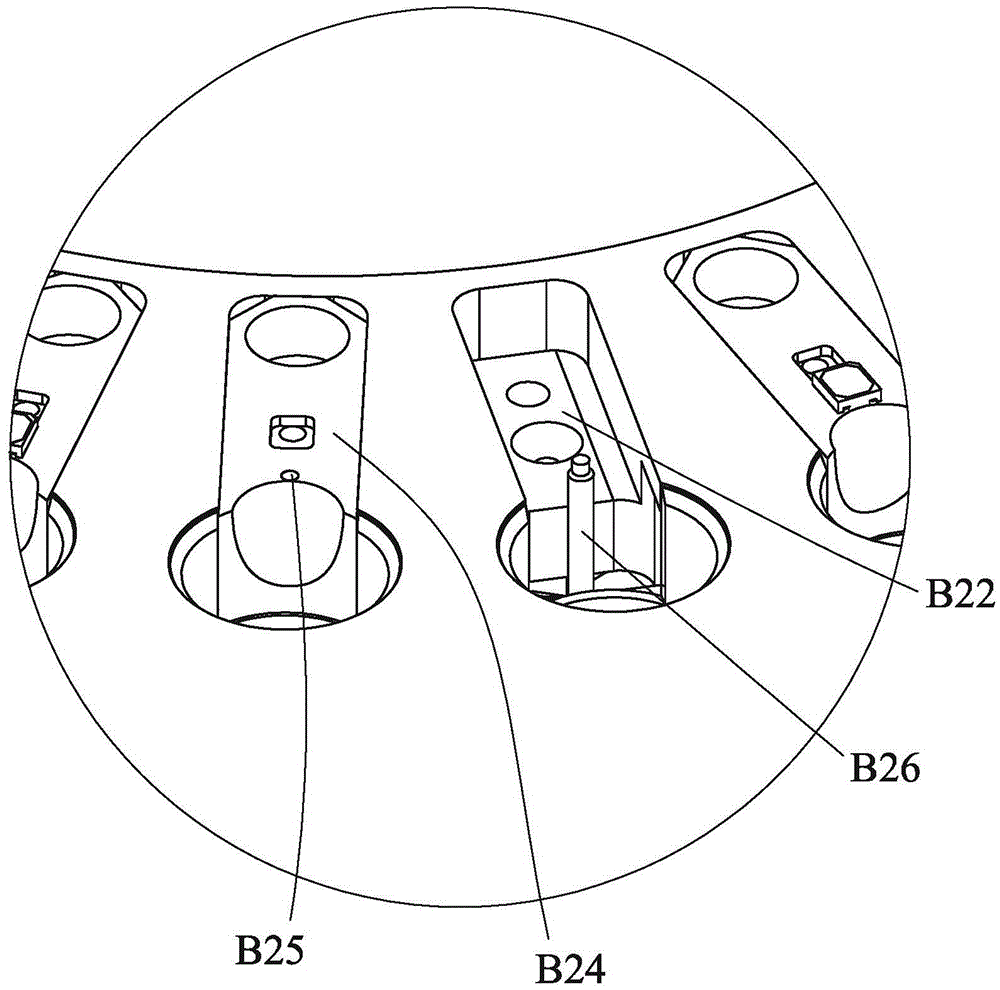

[0040] The sorting mechanism B is provided with a plurality of discharge outlets B21 which are respectively connected to discharge pipes (not shown in the figure) in a ring row on the machine table B2; Groove B22 is used to accommodate the block B24 that forms a part of the arc concave part B23 of the discharge port; each block B24 is provided with a detection hole B25 near the arc concave part B23, which is located be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com