Strengthening method for fillet part of crankshaft and stengthening device therefor

A technology for strengthening devices and rounding corners, applied in metal processing equipment and other directions, can solve problems such as inability to obtain effects, and achieve the effect of reducing tensile residual stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

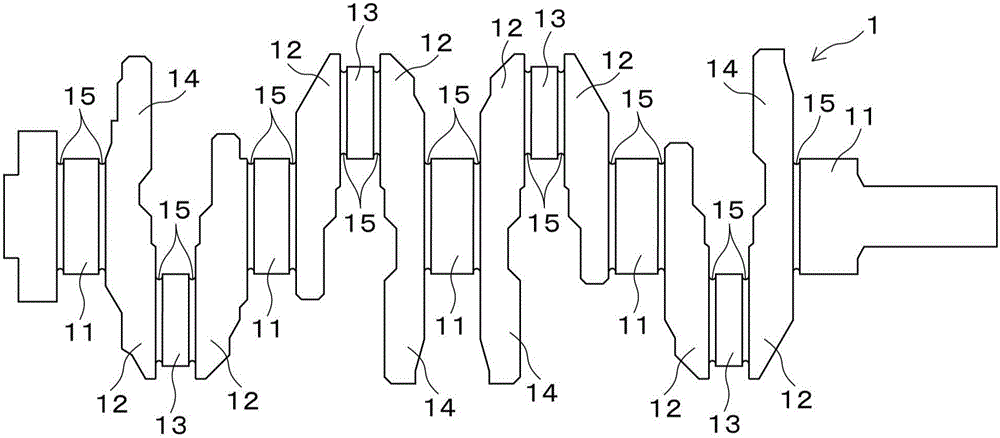

[0025] Hereinafter, one embodiment of the present invention will be described with reference to the drawings. figure 1 It is a side view showing the crankshaft 1 strengthened in this embodiment. The crankshaft 1 is formed by hot forging, and a crank arm 12 protruding radially is formed on a journal pin 11 as a rotating shaft, and a crank pin 13 is bridged at the ends of a pair of crank arms 12. A balance weight 14 is formed at the other end of one of the arms 12 . At both corners of each of the journal pins 11 and the crank pin 13 , rounded corners 15 formed of grooves having a substantially semicircular cross-section are formed.

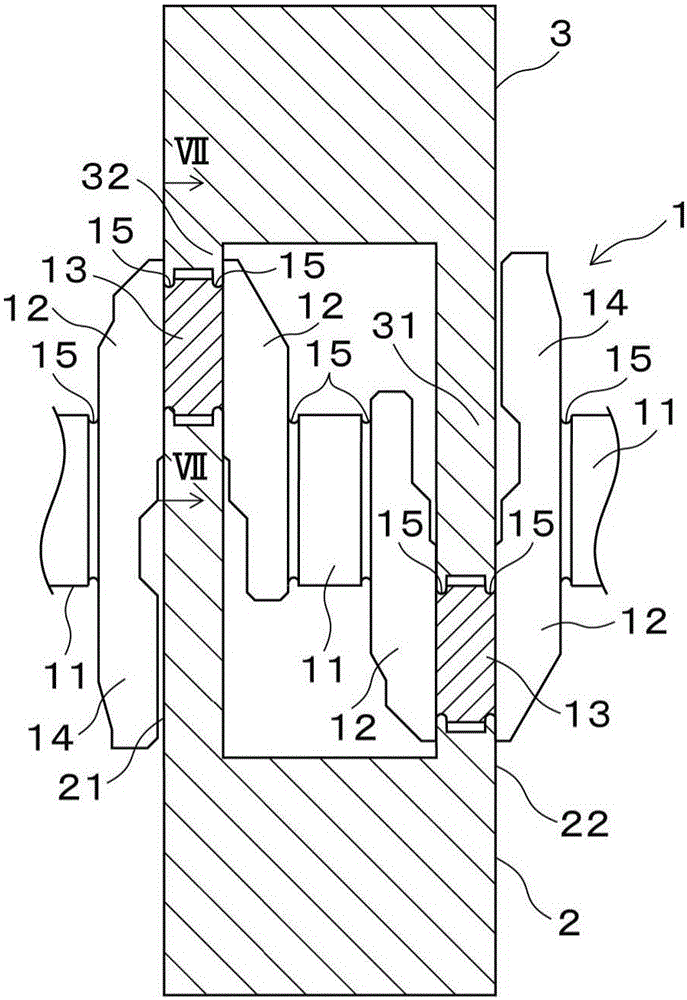

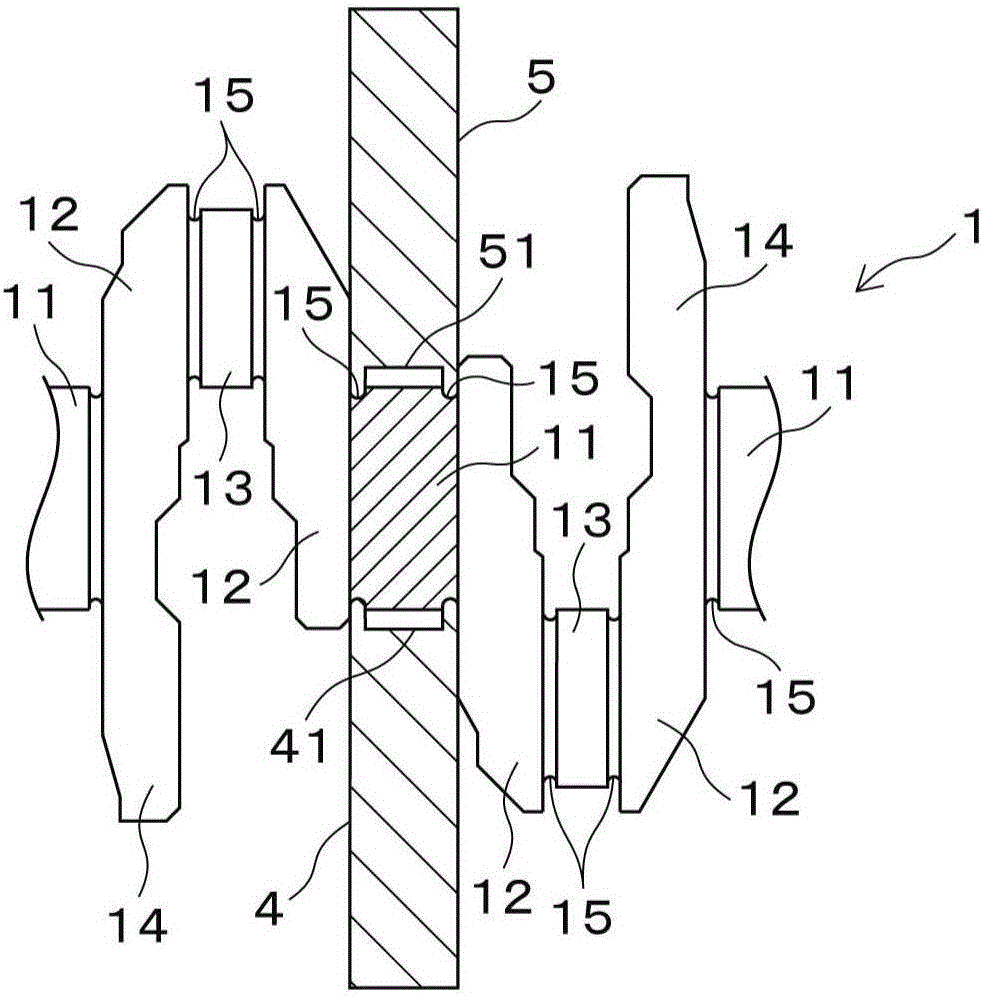

[0026] figure 2 It shows a state in which the fillet portion 15 of the crank pin 13 is plastically worked by the lower die 2 and the upper die 3 , and the crankshaft 1 is placed on the lower die 2 so that the crank pin 13 faces the vertical direction. A long first lower punch 21 extending upward is provided on one side of the lower die 2 . In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com