Manufacturing method of 7000 series aluminum alloy member

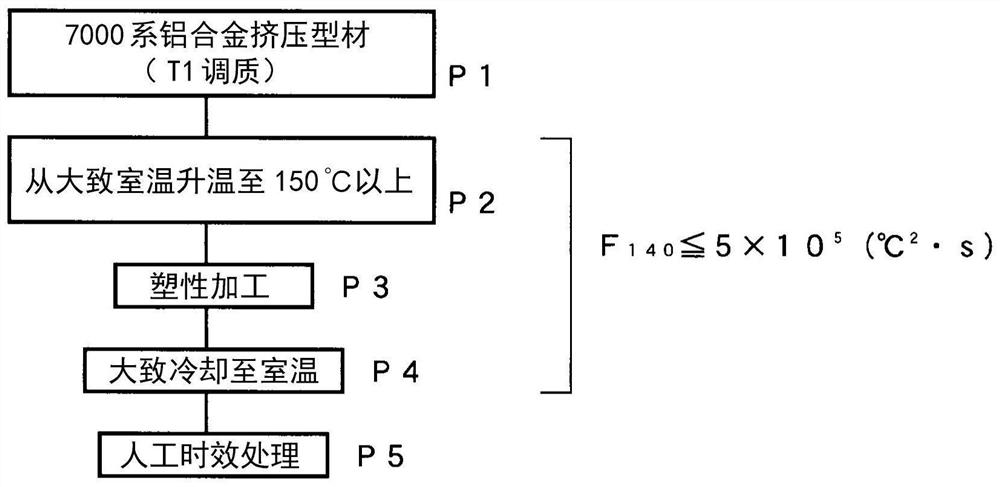

A manufacturing method and aluminum alloy technology, which is applied in the manufacturing field of 7000 series aluminum alloy components, can solve problems such as complex procedures, achieve low cost, reduce tensile residual stress, and prevent cracks from occurring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

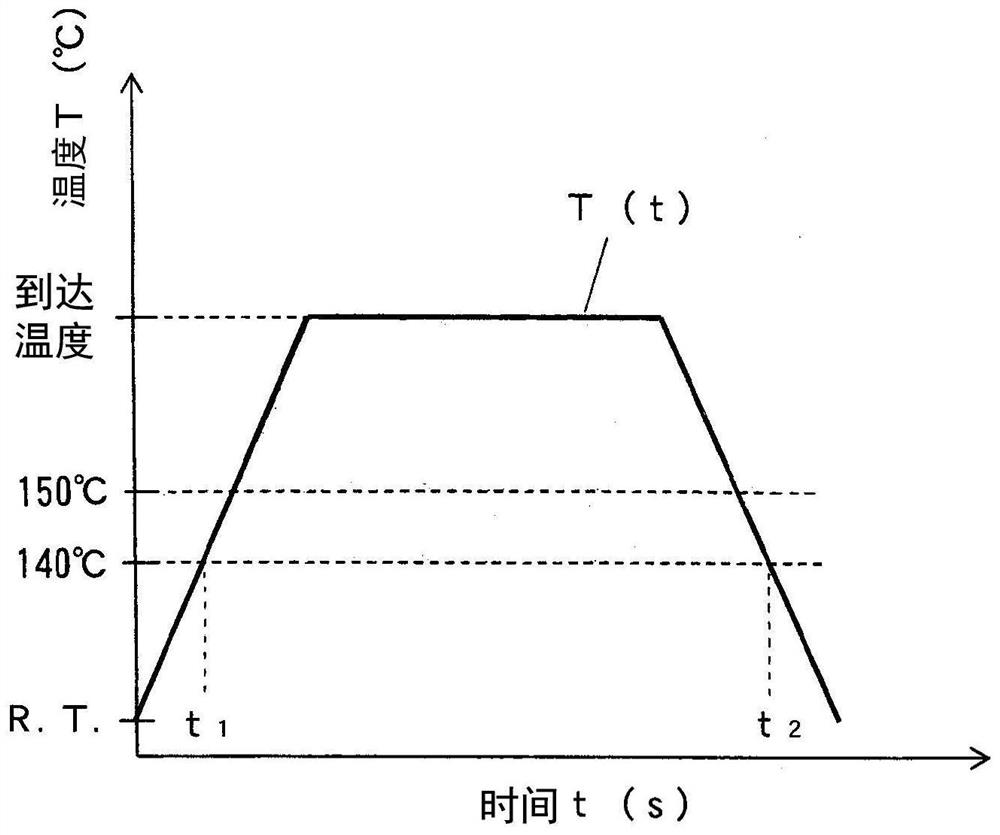

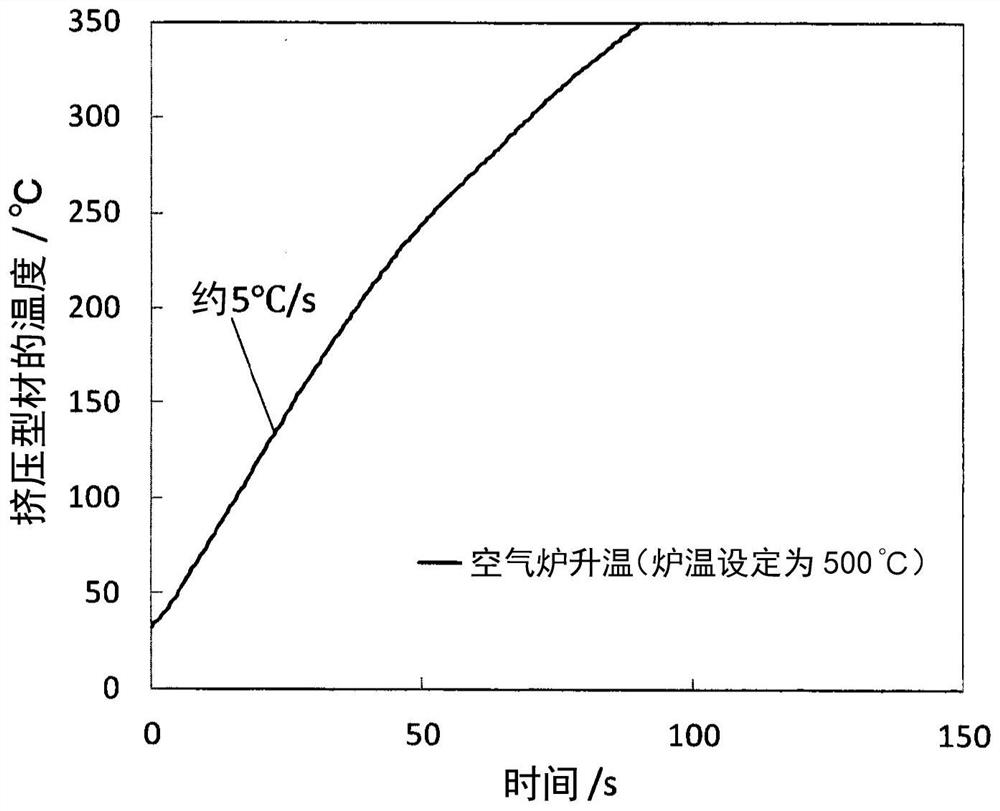

[0054] The 7000-series aluminum alloy extruded profile of T1 tuning was warmed from room temperature, so that the temperature was changed, and plastic processing (temperature processing) was performed at the reach temperature, and the temperature conditions of the crack occurred were investigated. In the 7000 series aluminum alloy, Mg: 1.4% by mass, Zn: 6.5% by mass, Cu: 0.15% by mass, Zr: 0.15% by mass, Cr: 0.03% by mass, Ti: 0.025% by mass, margin by Al and impurities constitute. The extruded profile is composed of: a rectangular profile having a cross section of about 50 mm × width of about 150 mm, has a pair of flanges having two hollow portions of 2 to 4 mm, a length of 150 mm; and an equal interval 3 pair of 3 lengths of a sheet of about 50 mm. This extruded profile is used, for example, as a raw material as a bumper reinforcement.

[0055] The extruded profile is disconnected to a certain length in the extrusion direction, and a test material for a temperature history and a...

Embodiment 2

[0061] For the 7000-series aluminum alloy extruded profiles of T1 injection, plastic processing is performed on various temperatures above room temperature, investigating the relationship between plastic processing temperature and stretchive residual stress. The composition of the 7000 series aluminum alloy was the same as that of Example 1. The extruded profile is a profile for, for example, a raw material used as a door anti-collision beam. Figure 5A As shown, a pair of flanges parallel to each other and a pair of web connecting the pair of flanges, the height is 35 mm, the flange and the web are perpendicular to each other. A flange (thin wall side flange) in a pair of flanges, a wall thickness of 2.2 mm, a width of about 34 mm, another flange (thick-walled side flange), a wall thickness of 5.6 mm, width of 40 mm. Further, the web thickness of the web is 2 mm, and the length is 27.2 mm.

[0062] The extruded profile is cut vertically to a certain length in the extrusion directi...

Embodiment 3

[0076] A 7000-series aluminum alloy extruded profile of the same T1 tem under Example 1 was used to form a JIS13B test piece (No. 1 to 23) from the longitudinal direction of the extrusion in the longitudinal direction. The test piece had a thickness of 3 mm. Among them, the test piece of No. 1 to 20 is warmed from the room temperature, so that the temperature reaches the temperature, the reach temperature holds a predetermined time, followed by cooling at various cooling speeds to room temperature, and performs aging treatment, measuring mechanical properties.

[0077] The arrival temperature of the test sheets of NO.1 to 20 is 150 ° C, 200 ° C, 250 ° C, 275 ° C, and the temperature rise of the reach temperature to maintain the reachable temperature of the oil bath (150 ° C, 200 ° C) or nitrogen stove (250 ° C, 275 ° C). Any of the reaching temperature is 30s, 60s, 90s, 150s, 180s, and the cooling method is natural empty or cold. From the cooling rate of the arrival temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com