Laser 3D printing platform for sand mold making with heated sand box

A 3D printing and heating technology, used in modeling tables, additive processing, etc., can solve the problems of prolonging the production cycle of parts, affecting equipment progress, increasing equipment costs, etc., and achieving the effect of less temperature loss, constant temperature and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

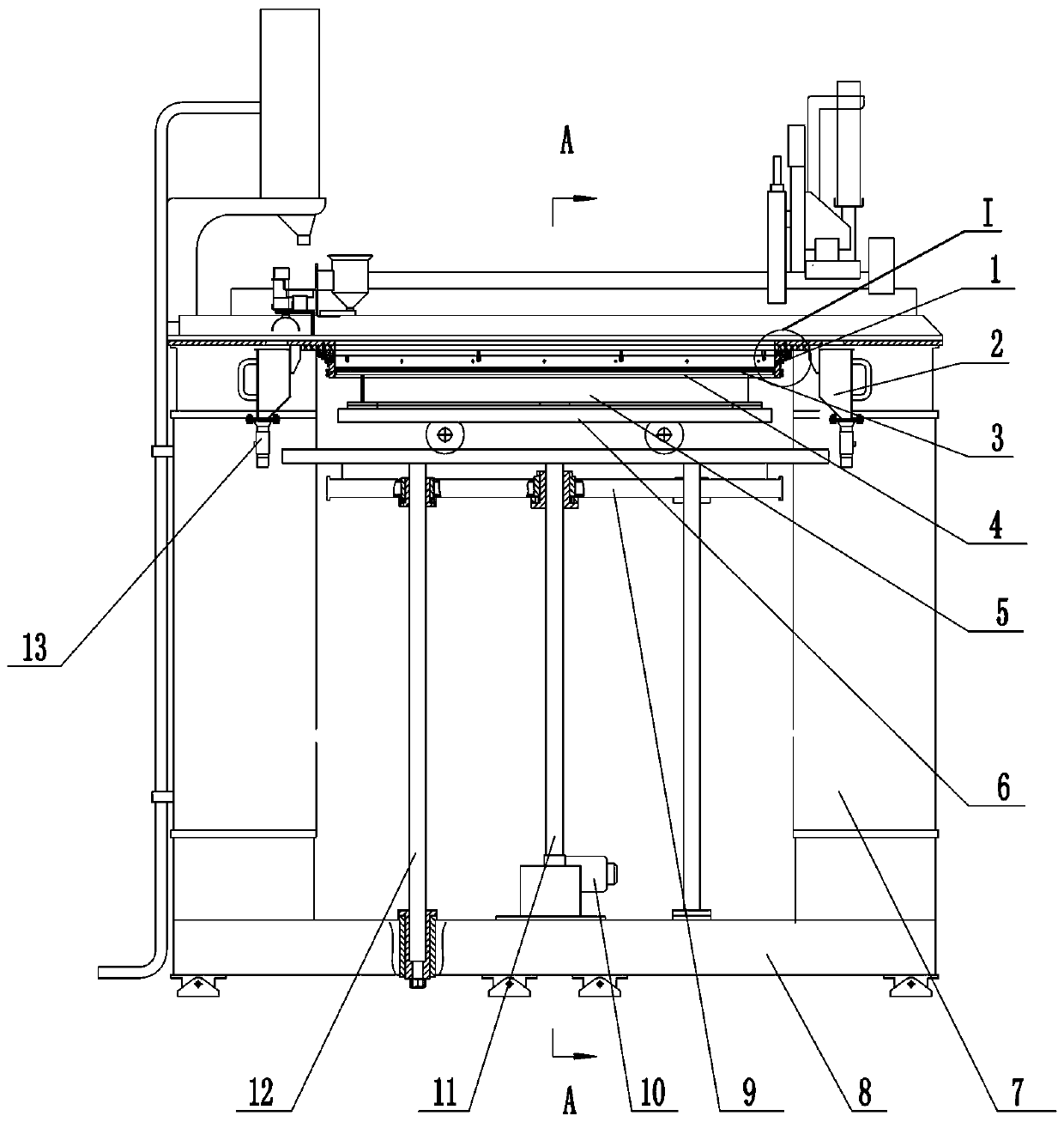

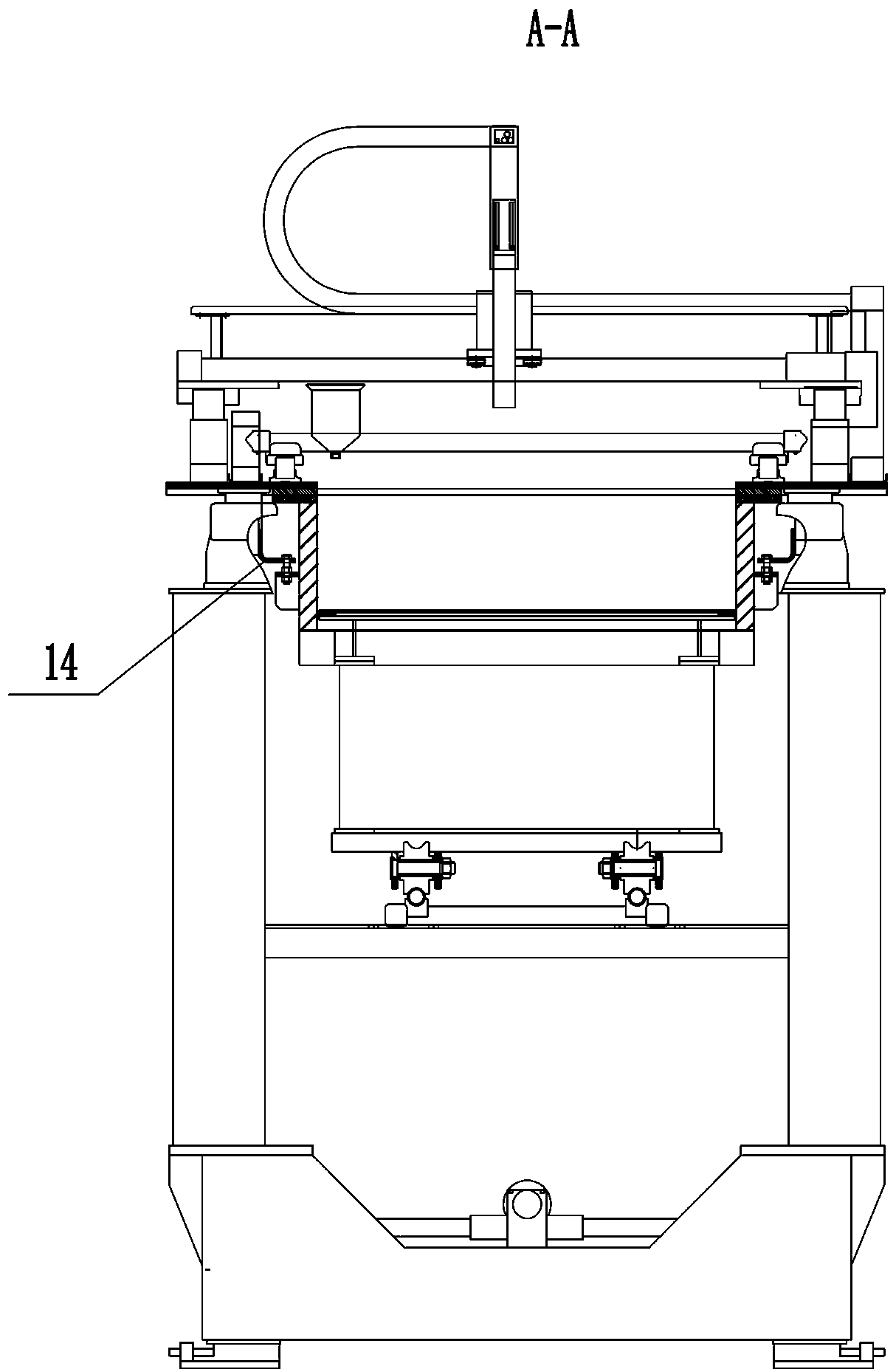

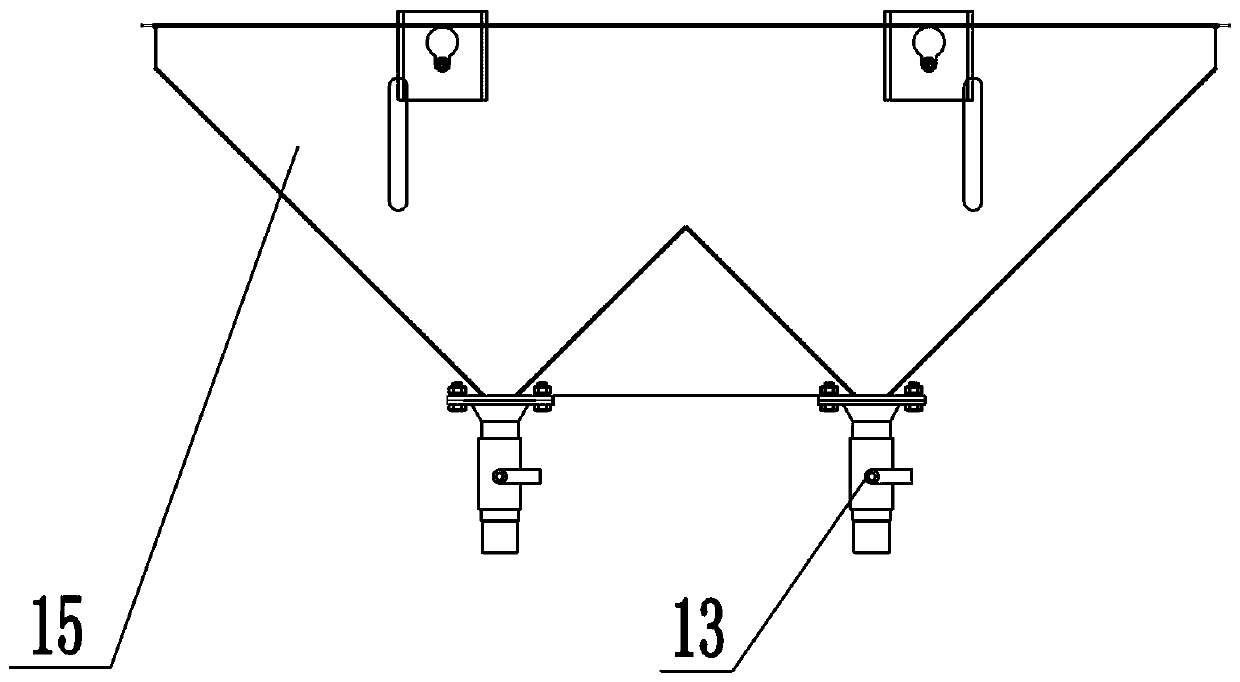

[0024] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as figure 1 , 2 , 3 and 4, the laser 3D printing platform for sand molding with a heated sand box of the present invention is characterized in that it includes a base 8, a column 7 arranged around the base 8, and a suspension frame 14 arranged on the top of the column 7 , the lifting system arranged on the base 8, the shifting system arranged above the lifting system, the sanding platform 3 arranged on the shifting system, surrounded by the sanding platform 3 and located in the printing area The upper heating flask 1 is set on the collecting box 2 on the side plate of the heating flask 1, and the top of the heating flask 1 is fixedly connected with the suspension frame 14 by bolts,

[0026] Described lifting system comprises lifting platform 9, and the lifting device that is connected with this lifting platform 9, des...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com