Pressure casting injector

A technology of injection device and plunger head, applied in the field of injection device for die casting, can solve problems such as casting wrinkles, and achieve the effect of suppressing casting wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

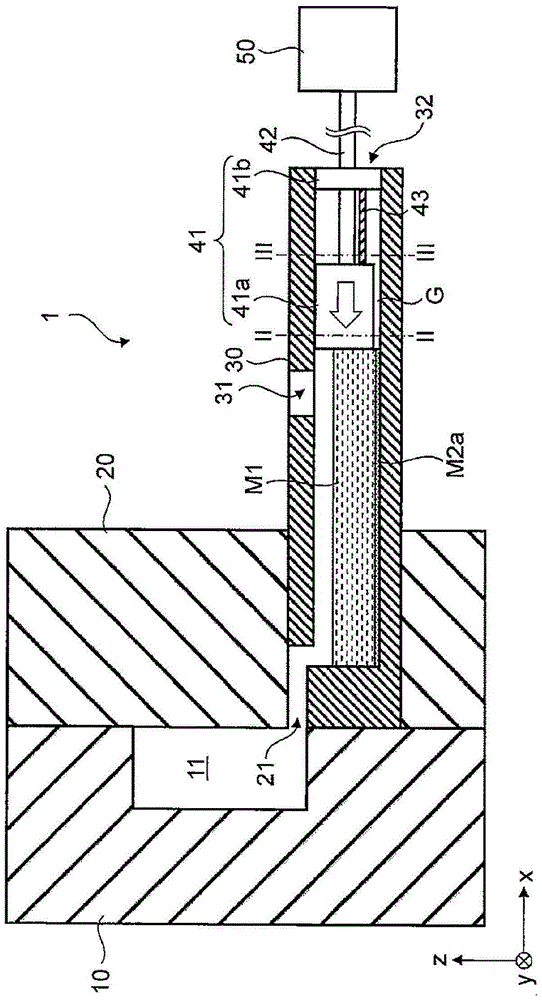

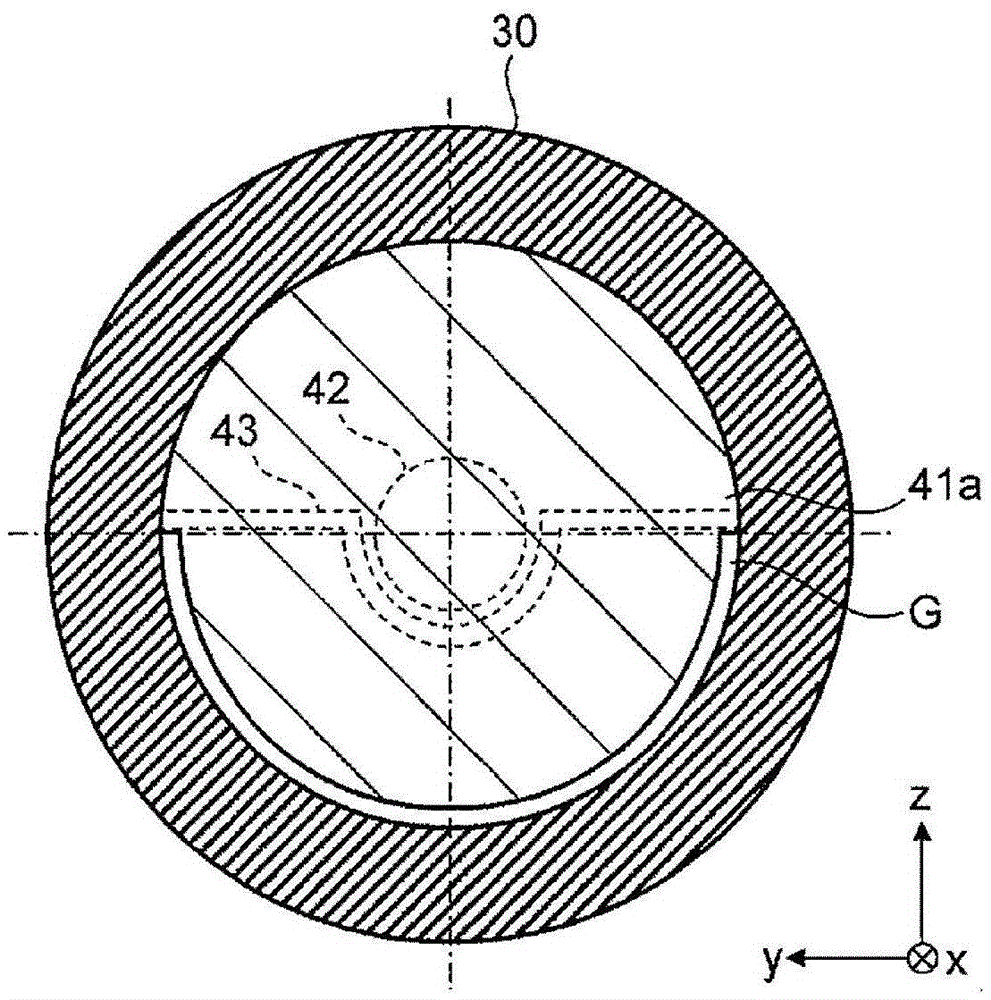

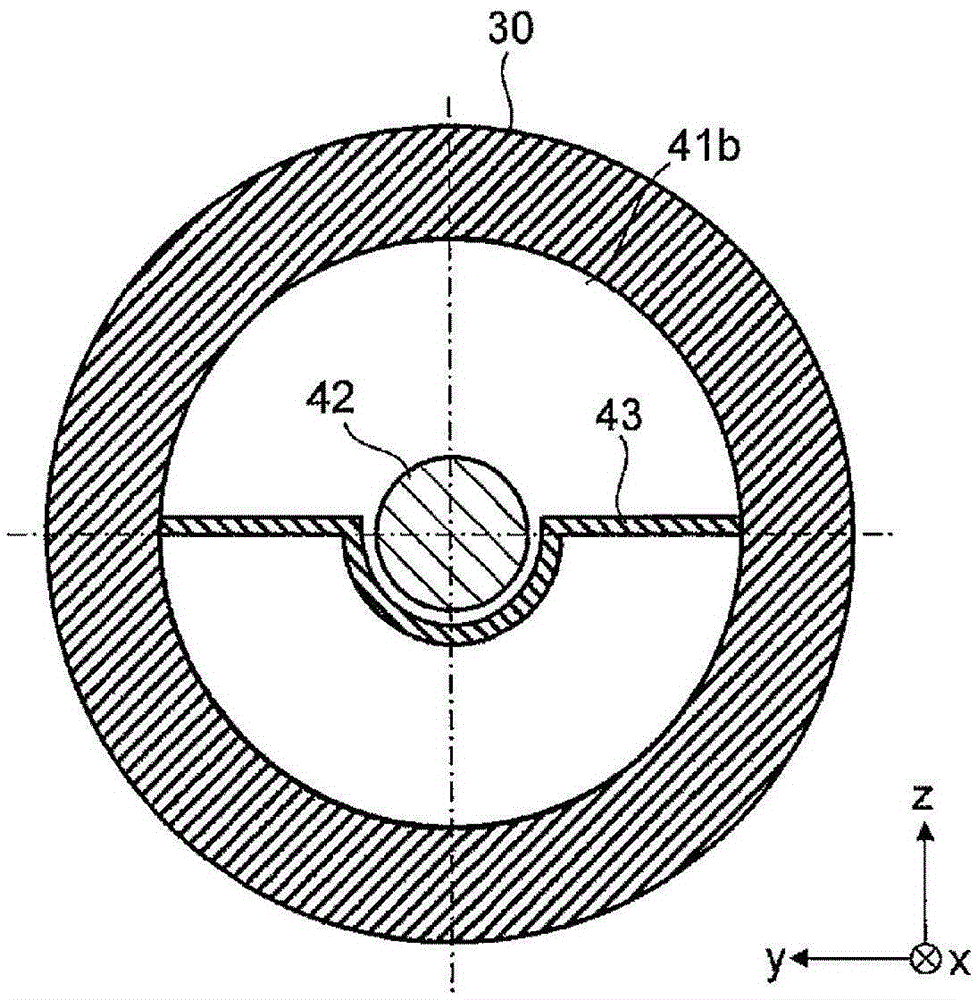

[0029] First, refer to figure 1 , a die casting apparatus using the injection apparatus according to the first embodiment of the present invention will be described. figure 1 It is a schematic cross-sectional view of a die casting apparatus using the injection apparatus according to the first embodiment of the present invention. like figure 1 As shown, the die casting apparatus includes a movable mold 10 , a fixed mold 20 , and an injection device 1 . Here, the injection device 1 according to the first embodiment of the present invention is an injection device for die casting, and includes a plunger sleeve 30 , a plunger head 41 , a plunger rod 42 , a protection plate 43 , and a drive source 50 .

[0030] Also, of course, figure 1 The right-handed xyz coordinates shown are used to facilitate the description of the positional relationship of the constituent elements. figure 1 The xy plane in the y plane constitutes the horizontal plane, and the z-axis direction is the verti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com