A machine tool with a spindle turning tool holder

A turning tool holder and spindle technology, which is applied to metal processing mechanical parts, large fixed members, metal processing equipment, etc., can solve the problems of difficult high-speed rotation of the cutter head, large X-direction travel of the machine base, and large investment in site area. Achieve the effect of increasing the utilization rate of the cloth knife, improving the indexing and positioning accuracy, and reducing the time for changing the knife

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

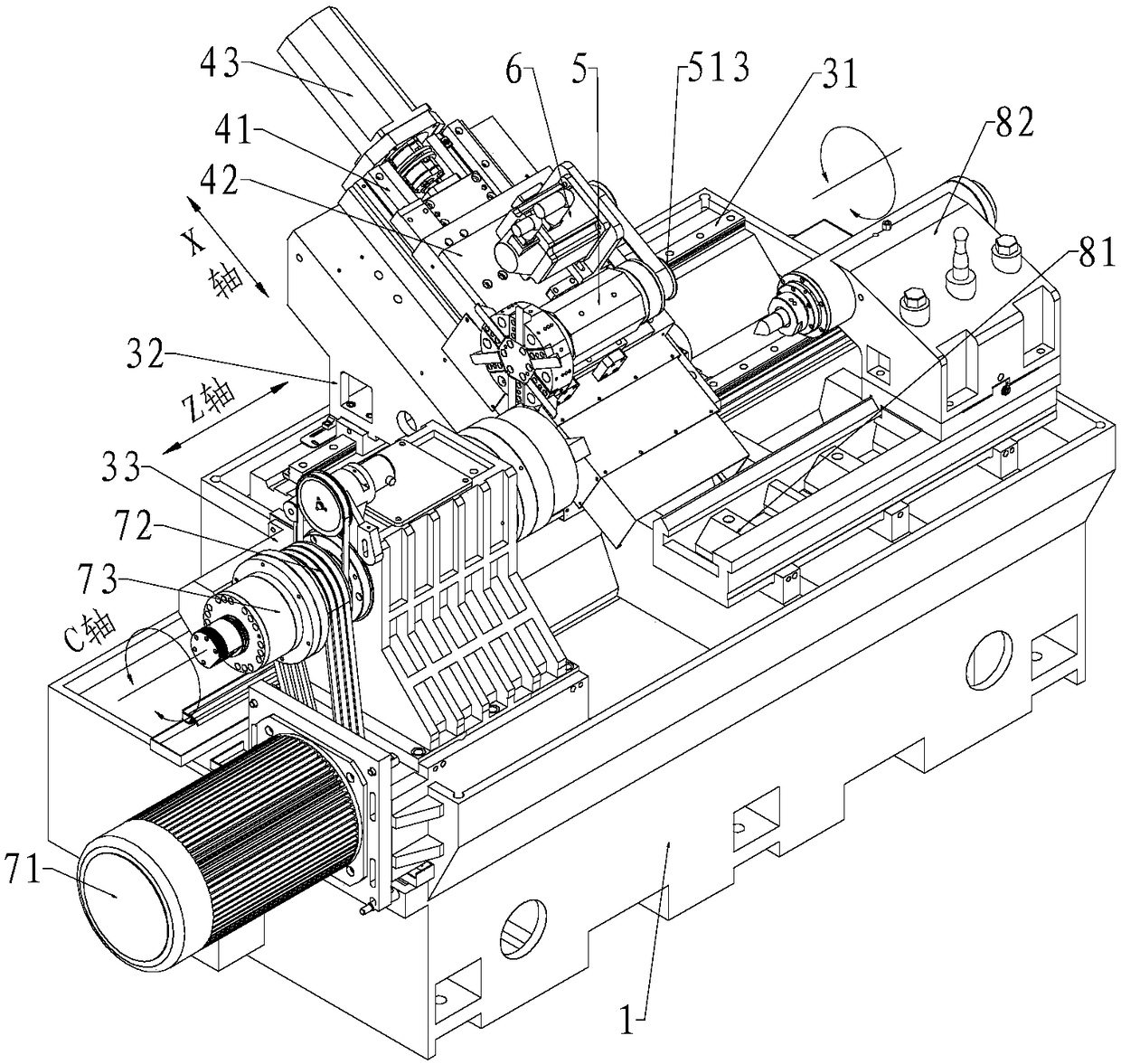

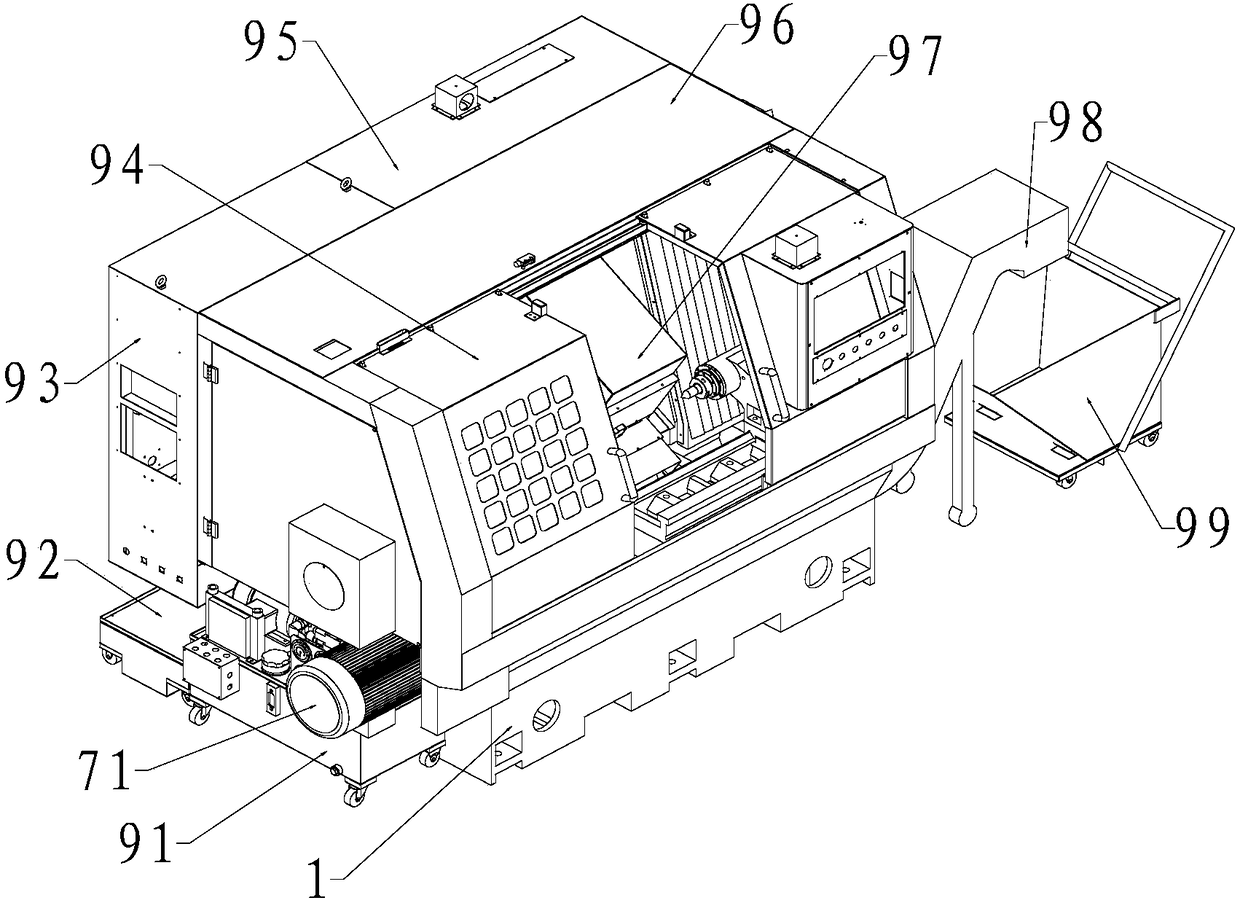

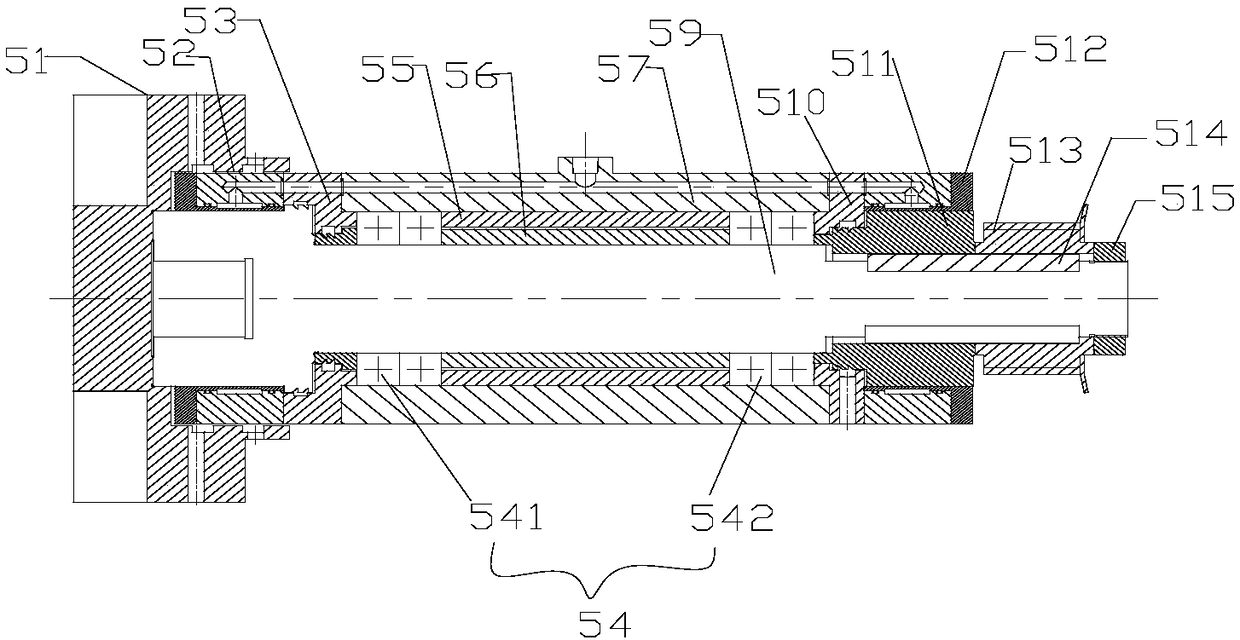

[0039] refer to Figure 1-Figure 5 , a machine tool with a spindle turning tool post described in this embodiment, including a machine base 1, a Z-guiding rail 31, an inclined bed 32, a Z-directing motor 33, an X-guiding rail 41, an X To the slide plate 42, the X-direction motor 43, the spindle turning tool rest 5 and the spindle turning tool rest driving motor 6; the upper surface of the inclined bed 32 is an inclined surface, and the inclined bed 32 is installed on the Z guide rail 31, and is guided by Z Drive the inclined bed 32 to the motor 33 to slide on the Z guide rail 31; the X guide rail 41 is installed on the inclined bed 32, the X slide plate 42 is installed on the X guide rail 41, and the X direction is driven by the X direction motor 43. The slide plate 42 slides on the X-guiding rail 41; the spindle turning tool rest 5 is installed on the X-direction sliding plate 42 of the inclined bed 32, and the spindle turning tool rest 5 is driven to rotate by the spindle tu...

Embodiment 2

[0056] The difference between this embodiment and Embodiment 1 is that a hydraulic oil inlet is provided on the upper surface of the box body 57, and an oil pipeline is installed inside the box body 57. The oil inlet of the hydraulic oil is connected to the oil pipeline, and the oil pipeline is connected to the front Both the holding brake 52 and the oil inlet pipeline 516 of the rear holding brake 512 are connected. The hydraulic oil enters the oil inlet pipeline 516 from the oil inlet of the box body 57, and then reaches the annular hydraulic chamber 519 to make the diaphragm 520 in the brake assembly produce elastic deformation, and then use the elastic deformation of the diaphragm 520 to make the brake assembly move along the The inner hole of the diaphragm 520 embraces the main shaft 59 and the locking spacer 511 in a circumferential direction, thereby realizing accurate positioning.

Embodiment 3

[0058] The characteristic of this embodiment is that: the Z-direction guide rail and the Z-direction motor are not arranged on the base. The inclined bed is fixedly installed on the machine base; others are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com