Operation mechanism for teaching robot tongs

A technology for teaching robots and operating mechanisms, applied in the field of robot teaching, can solve the problems of difficult basic principles, mechanical assembly, and inability to observe the transmission of the transmission unit, and achieve the effect of good application prospects, simple components, and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings of the specification. The following embodiments are only used to illustrate the technical solutions of the present invention more clearly, and cannot be used to limit the protection scope of the present invention.

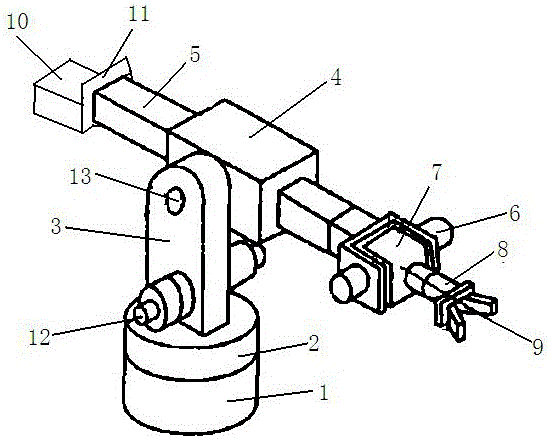

[0017] Such as figure 1 As shown, the gripper operating mechanism of the teaching robot of the present invention includes a round table base 1, a rotating round table 2 is installed on the upper part of the round table base, and a supporting plate 3 is installed on the upper part of the rotating round table 2, the supporting plate 3 A movable joint seat 4 is provided on one side of the movable joint seat 4, the movable joint seat 4 is fixed on one side of the support plate 3 through a rotary joint 13, and a horizontally arranged movable arm 5 is embedded in the movable joint seat 4, the movable arm 5 A U-shaped connecting piece is hinged on the front end of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com