Novel building material cutting device

A cutting device and new building material technology, applied in metal processing and other directions, can solve problems such as damage to pipes, increase cutting processing costs, and reduce the performance of cutting devices, so as to avoid damage, improve performance and scope of application, and ensure cutting accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

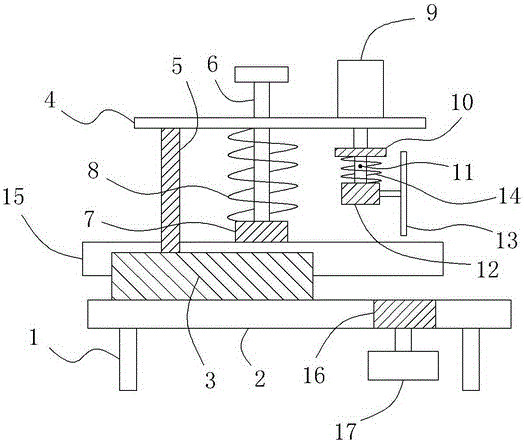

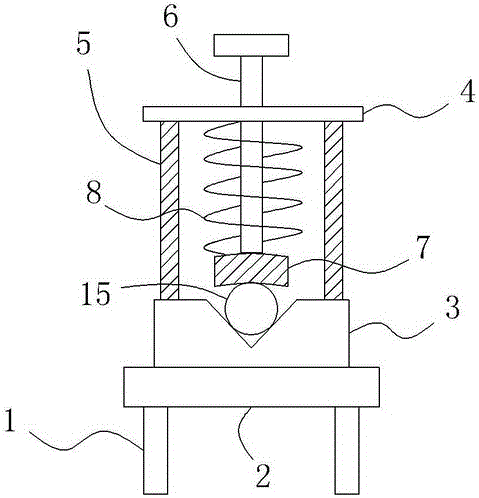

[0013] like figure 1 and figure 2 As shown, a new type of building material cutting device includes a bracket 1 and a base 2 located on the bracket 1. On the left side of the top of the base 2, a support 3 extending left and right in the horizontal direction is provided. On the top plane of the support 3 There is also a V-shaped groove extending along the length direction of the support 3, a top plate 4 is also provided above the support 3, and at least one is also connected between the bottom end of the top plate 4 and the top end of the support 3. The vertically arranged strut 5 also has a sliding hole (not shown in the figure) on the top plate 4, and a vertically arranged pressing rod 6 is embedded in the sliding hole, and at the same time, a top of the pressing rod 6 is provided with The handle is provided with a pressure plate 7 at the bottom of the pressure rod 6, and a first coil spring 8 is also sleeved on the pressure rod 6 below the top plate 4; a hydraulic cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com