Surface aerator with vertical motor for sewage treatment system

A sewage treatment system, surface aerator technology, applied in water/sludge/sewage treatment, water aeration, sustainable biological treatment, etc., can solve the problem of not being able to effectively prevent rainwater from intruding into the motor end

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

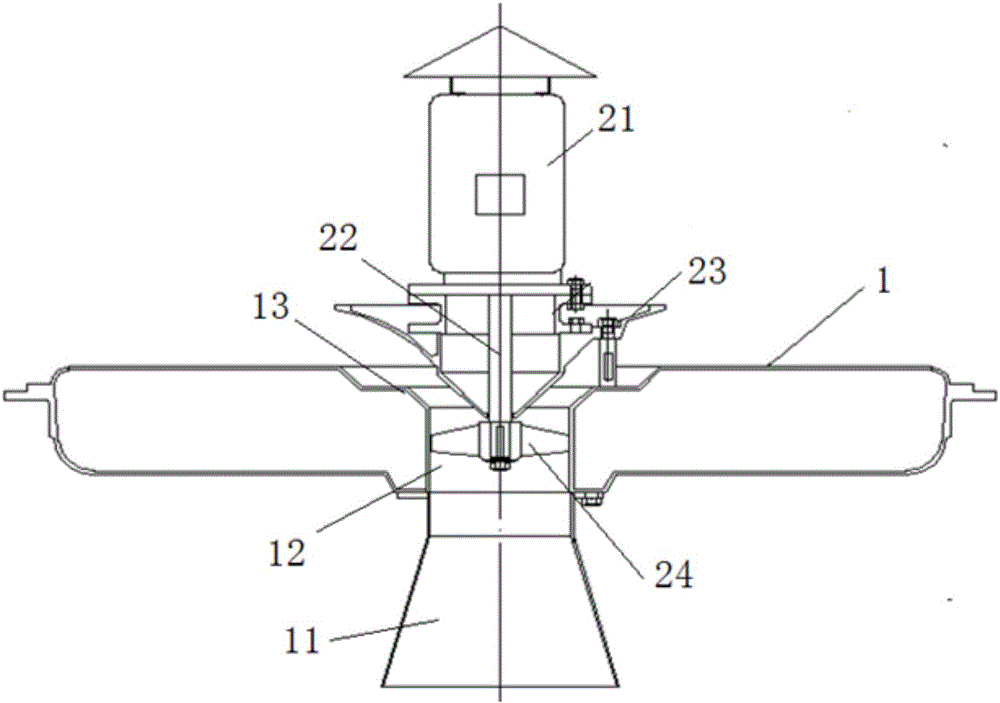

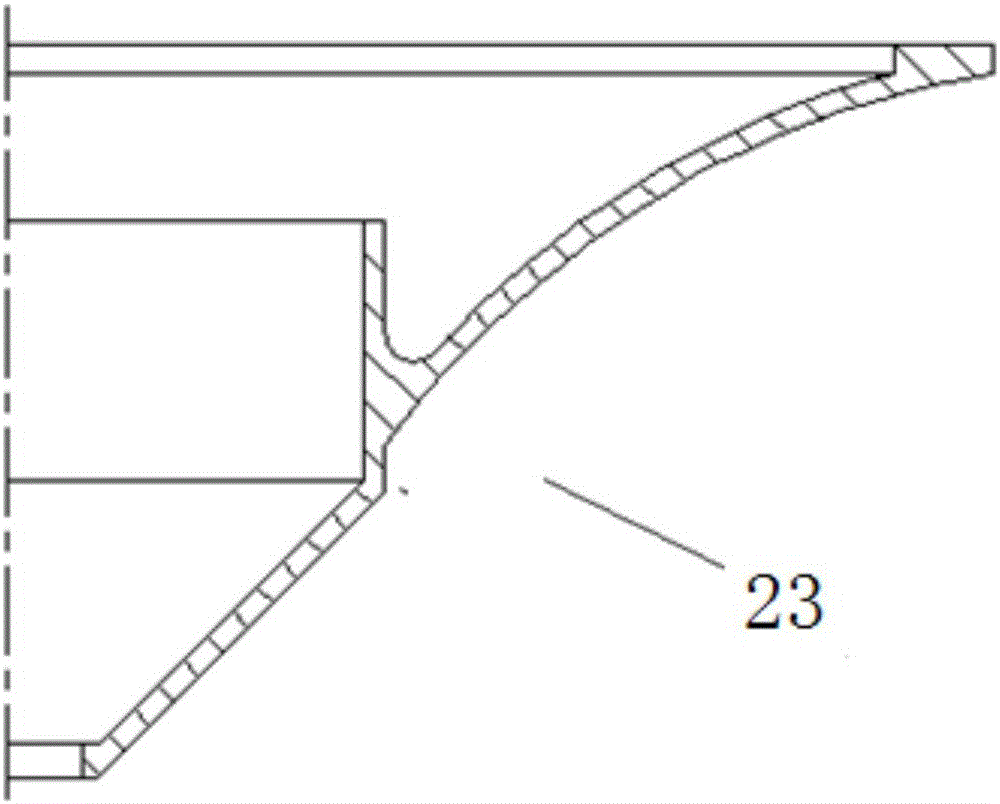

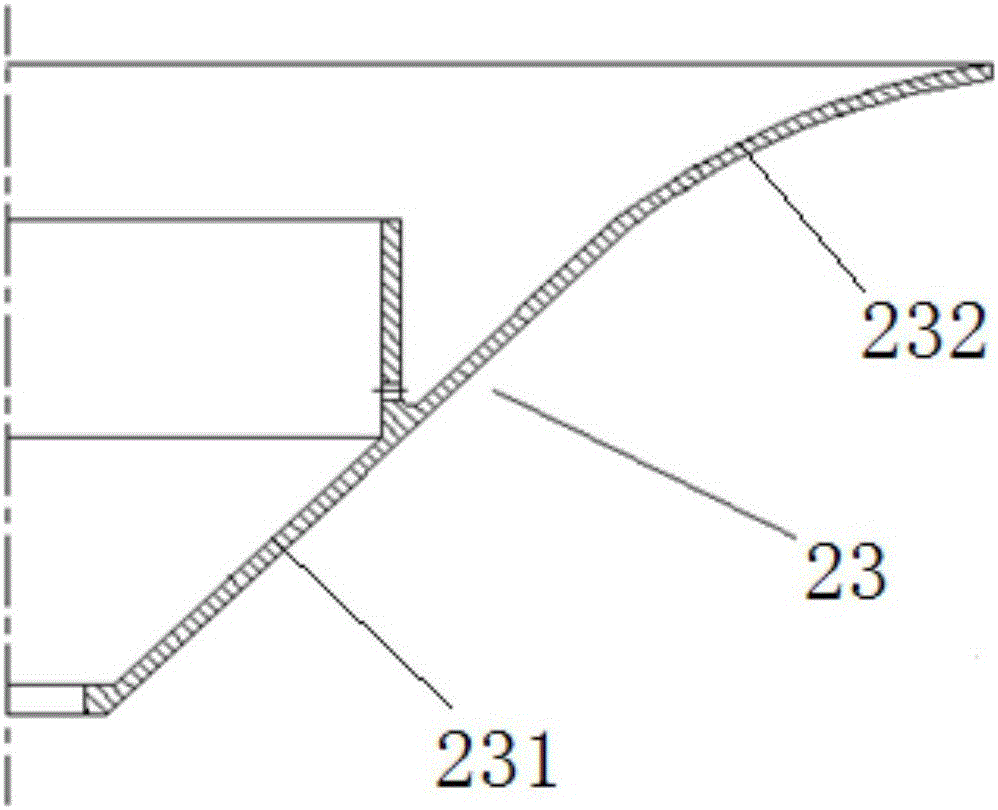

[0024] Example 1, such as figure 1 As shown, a surface aerator includes a buoy 1, a motor 21 installed on the buoy 1, and an axial flow impeller 24. The horizontal center of the buoy is provided with a water absorption channel 12 connected up and down. A water inlet 11 communicated with the water absorption channel 12 is provided, a water outlet 13 communicated with the water absorption channel 12 is provided on the upper part of the buoy, the motor 21 is arranged above the water outlet 13 and vertically arranged, and the output shaft of the motor is placed downward and The pump shaft 22 is connected, and the motor 21 is provided with a shroud 23 surrounding the pump shaft 22. The shroud 23 is set corresponding to the water outlet 13. The bottom of the pump shaft 22 is exposed from the shroud 23 and extends into the water-absorbing The channel 12 is also equipped with the above-mentioned axial flow impeller 24 .

[0025] In the water suction channel 12, the motor 21 drives t...

Embodiment 2

[0035] Embodiment 2, in order to make the rainproof cover 3 not only play the role of heat dissipation of the motor but also play the role of rainproof. Such as Figure 6 As shown, the present invention is provided with an annular ventilation ring 32 between the rain shield cap 31 and the end cover 25 , and the motor end cover 25 is fixed to the motor body by screws 251 . The ventilation ring 32 has ventilation openings 321 distributed along the circumferential direction, and an annular rain-shielding ring 33 is provided on the inner peripheral side of the ventilation ring. The ventilation ring 32 is used to realize ventilation and heat dissipation of the motor, while the rain-shielding ring 33 can effectively prevent rainwater from intruding into the motor.

[0036] Such as Figure 7 As shown, the ventilation ring 32 is in the shape of a rectangular strip after being unfolded, and the ventilation opening 321 is a rectangular notch provided at the bottom of the ventilation r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com