High-performance aluminum alloy bridge stand

An aluminum alloy, high-performance technology, applied in the direction of electrical components, etc., can solve the problem of poor dust-proof and heat-dissipating performance of the bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

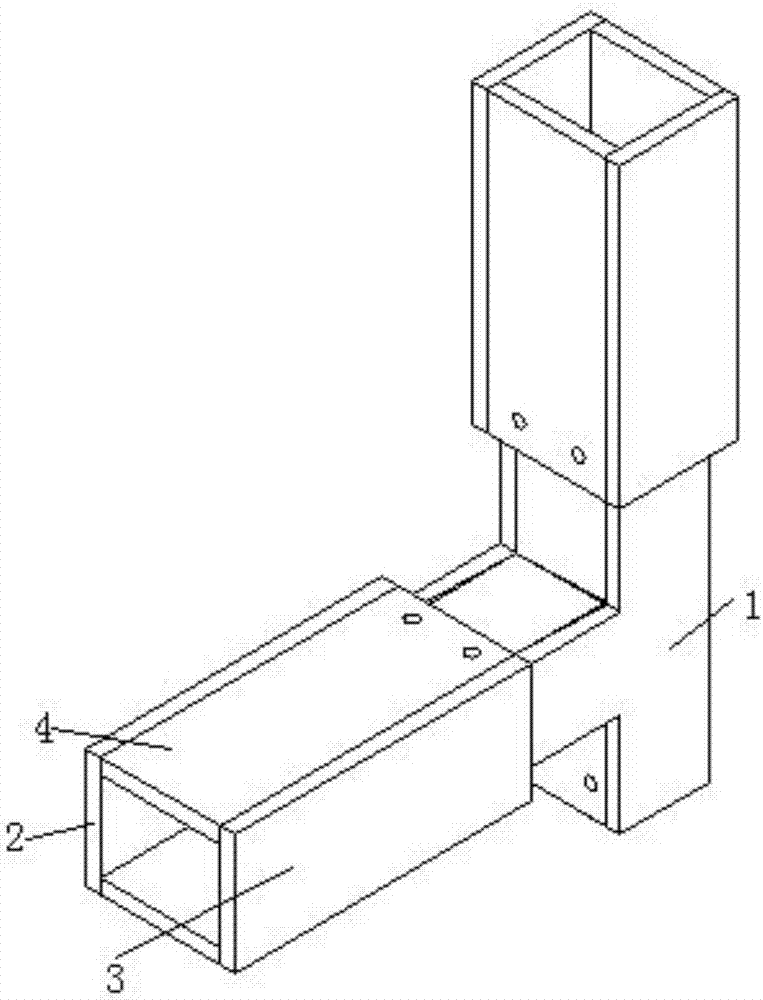

[0034] As shown in the figure, a high-performance aluminum alloy bridge includes two bridge bodies and bridge connectors;

[0035] The bridge connecting piece includes a connecting piece bottom plate, a connecting piece side plate, a connecting piece top plate and a terminal head. The connecting piece side plate is arranged between the connecting piece top plate and the connecting piece bottom plate, and the connecting piece top plate and the connecting piece bottom plate are connected to each other. The side plates of the connecting piece are symmetrical, and the bottom plate of the connecting piece and the top plate of the connecting piece are both "T"-shaped structures. The connecting piece side plate includes the first test board, the second test board, the third test board, the fourth test board and the fifth test board. A first connecting end, a second connecting end and a third connecting end are formed between the bottom plate of the connecting piece, the side plate of the...

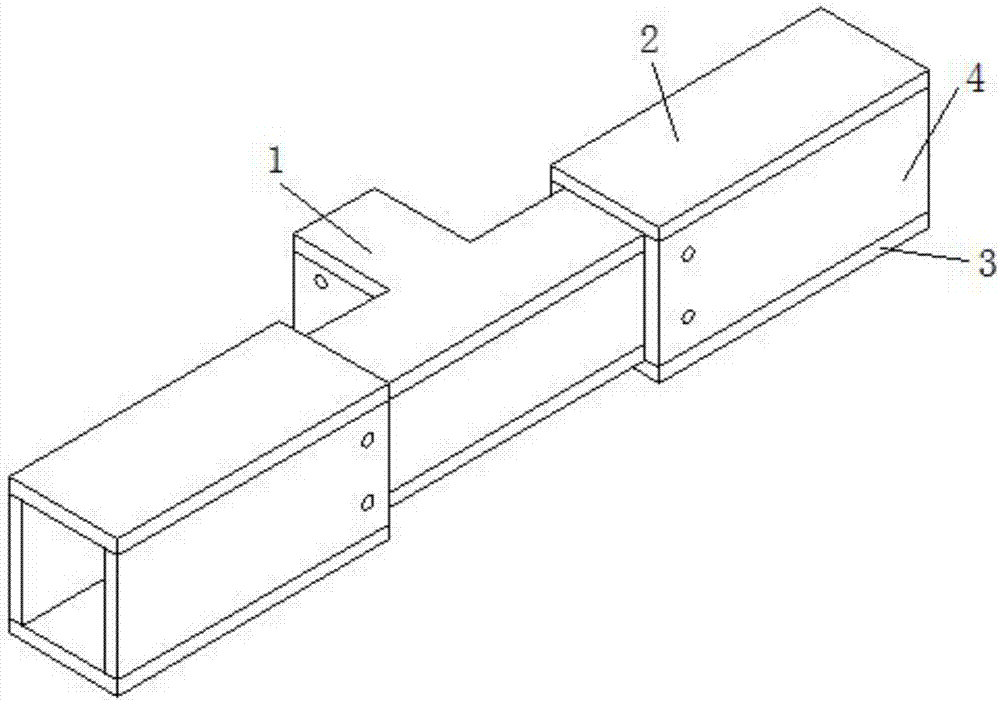

Embodiment 2

[0043] As shown in the figure, a bridge connector for a bridge frame. The difference from Embodiment 1 is that the terminal head is set at the second connection end through the first connector; the two bridge bodies are set at the second connection end through the second connector. A connecting end and a third connecting end, and the second connecting member is a second bolt and a second nut.

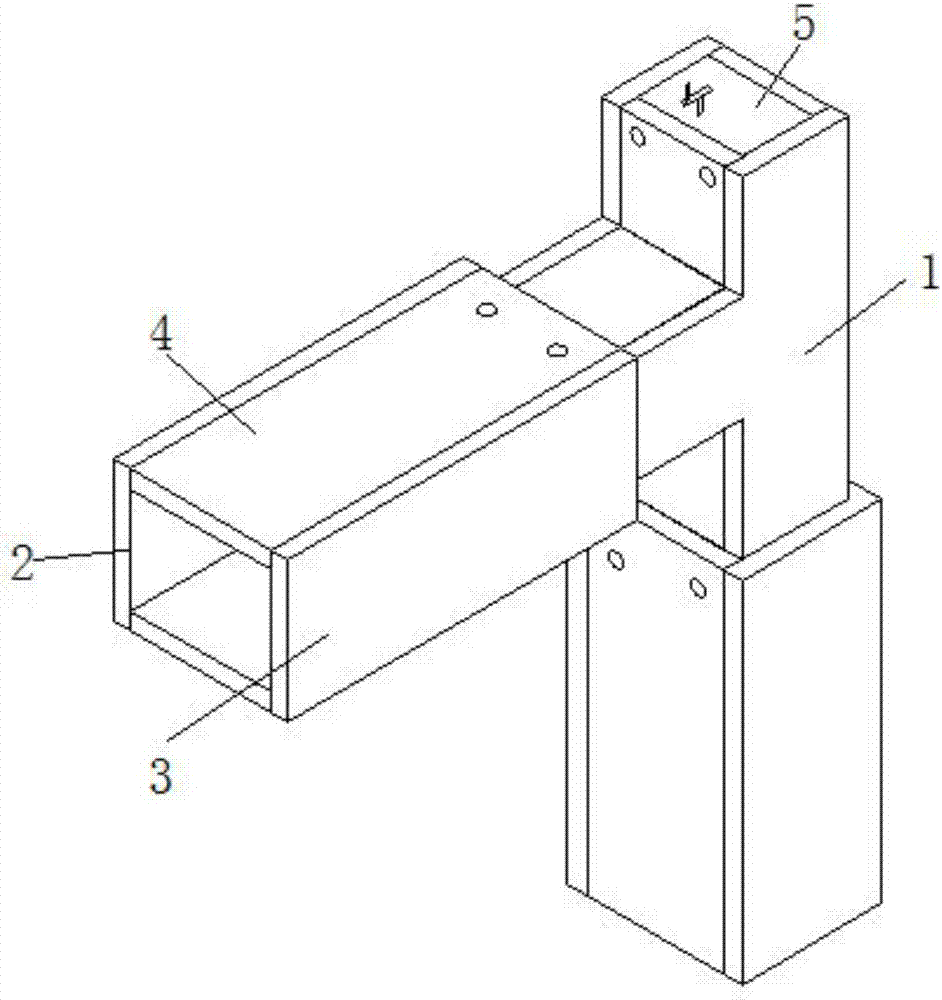

Embodiment 3

[0045] As shown in the figure, a bridge connector for a bridge frame. The difference from Embodiment 1 is that the terminal head is set at the third connecting end through the first connector; the two bridge bodies are set at the second connector through the second connector. A connecting end and a second connecting end, and the second connecting member is a second bolt and a second nut.

[0046] The invention can control the rotation of the turntable through a hand crank. When the vents on the turntable coincide with the vents on the first sealing plate, ventilation and heat dissipation can be realized. When the vents on the turntable coincide with the vents on the first sealing plate When staggered, it can be sealed and dustproof, and the position of the terminal head is optional, which can play a role of straight or curved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com