An automatic feeding color testing machine and its use method

An automatic feeding and color testing machine technology, applied in the field of color testing machines, can solve the problems of difficulty in simulating multiple additions, time-consuming and labor costs, and uncontrollable amount of release, saving manpower and time, reducing labor Errors, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

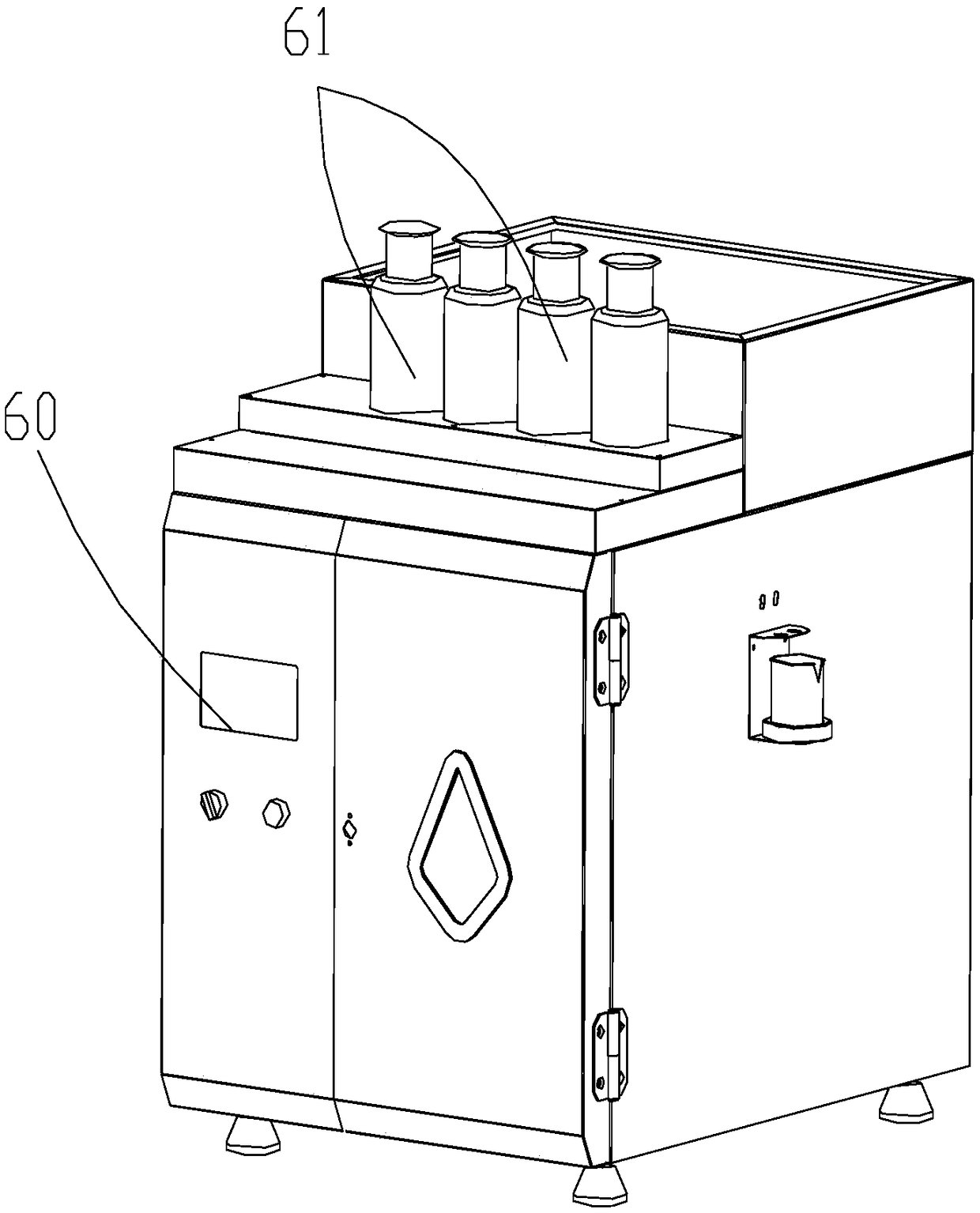

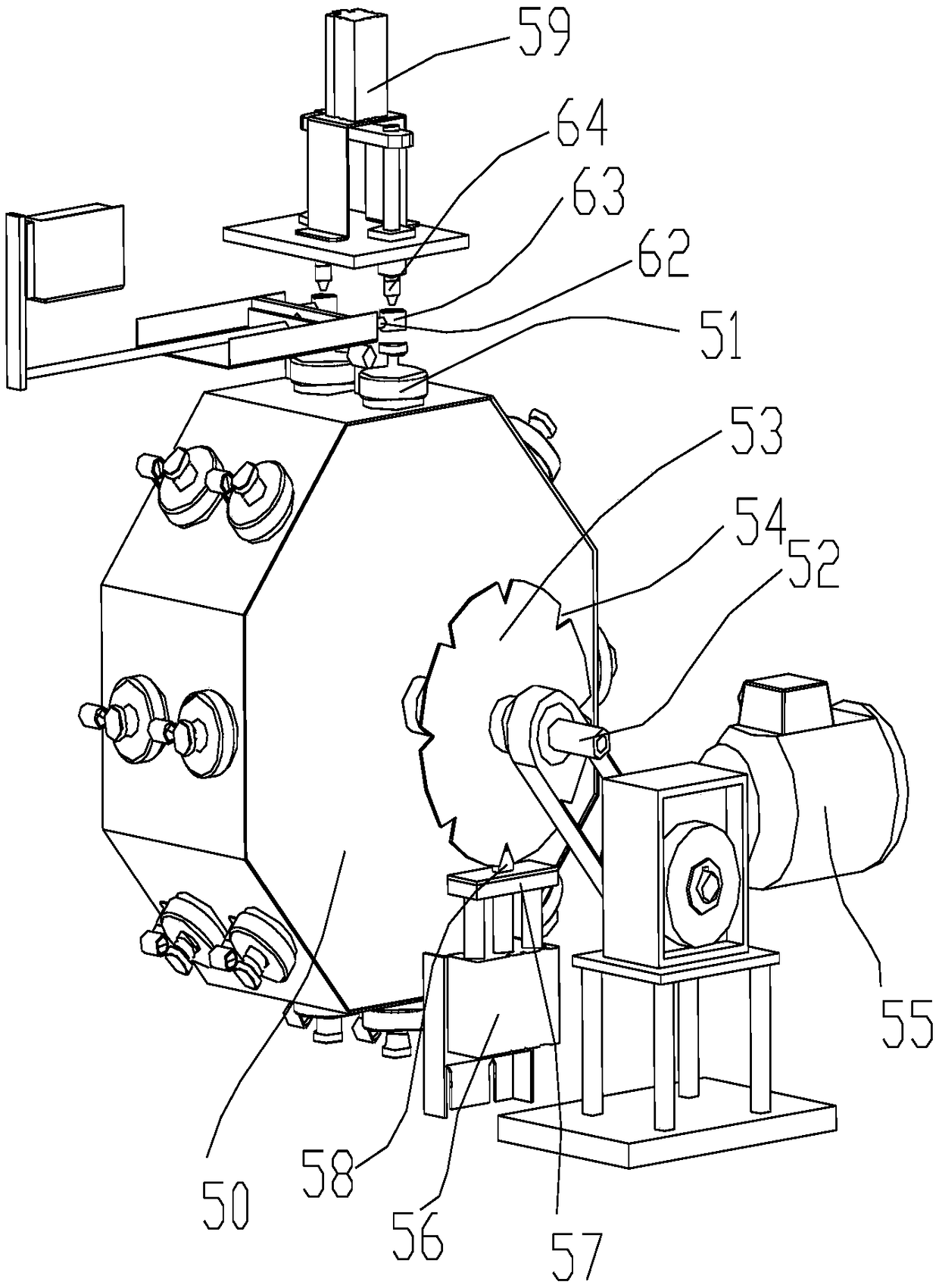

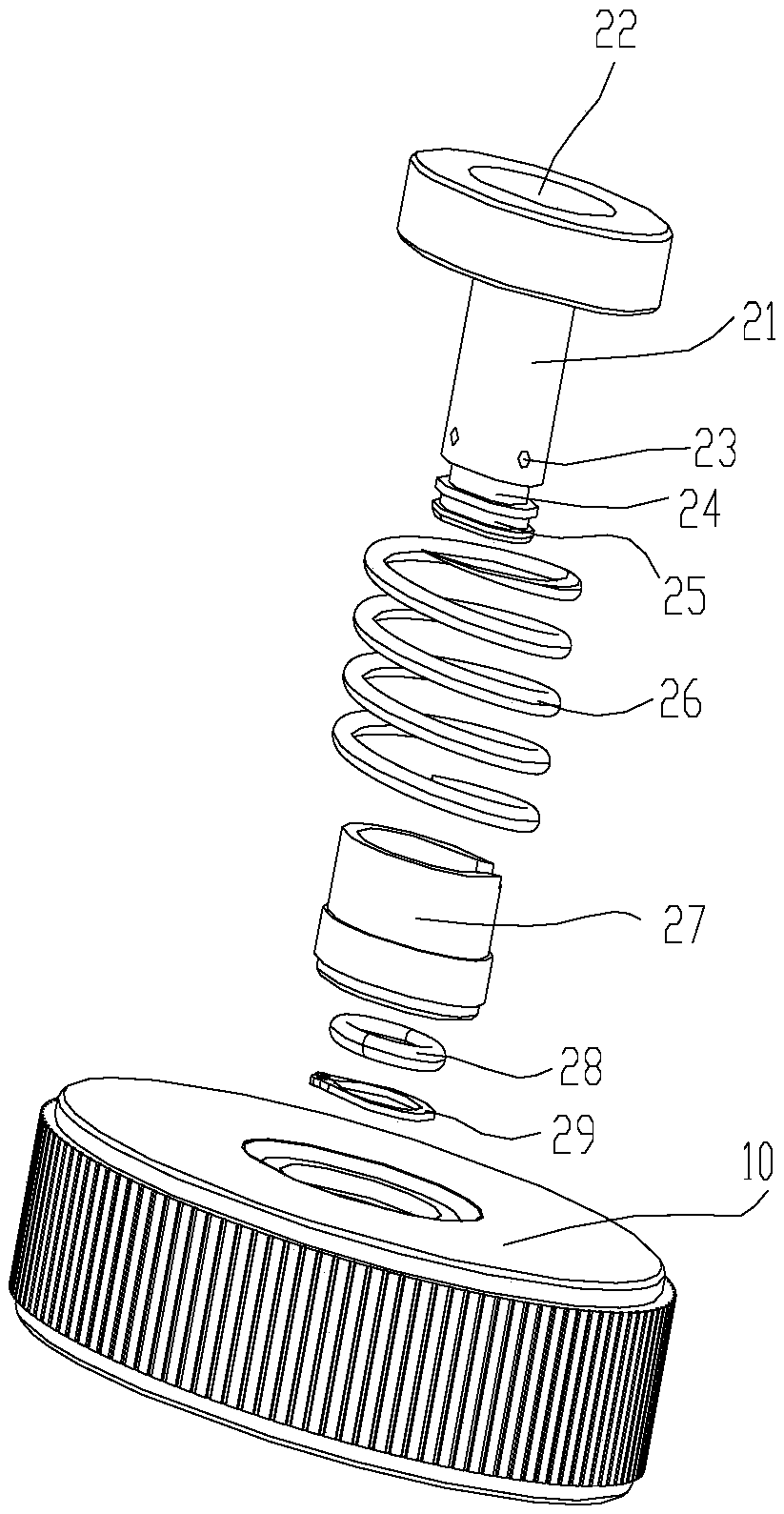

[0044] like Figure 1-7 As shown, an automatic feeding color testing machine includes a housing, a rotating mechanism, a dyeing cup 51, an auxiliary agent adding mechanism and a data processor; The auxiliary agent adding mechanism and the data processor are both arranged in the accommodating cavity. like figure 2 As shown, the rotating mechanism includes a rotating cage 50 and a power mechanism for driving the rotating cage 50 to rotate; the rotating cage 50 is a three-dimensional member formed by regular N-gon stretching, so that the rotating cage is formed with N side walls ; The side wall of the tumbler 50 is provided with at least one inwardly recessed holding tank; the dyeing cup 51 is arranged in the holding tank; as Figure 3-7 As shown, the dyeing cup 51 includes a cup cover, an injection cup and a cup body 46; the cup cover includes a movab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com