A filling compaction device

A technology of compaction device and road roller, which is applied in the directions of roads, road repair, roads, etc., to achieve the effect of improving turning radius, good off-road performance and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

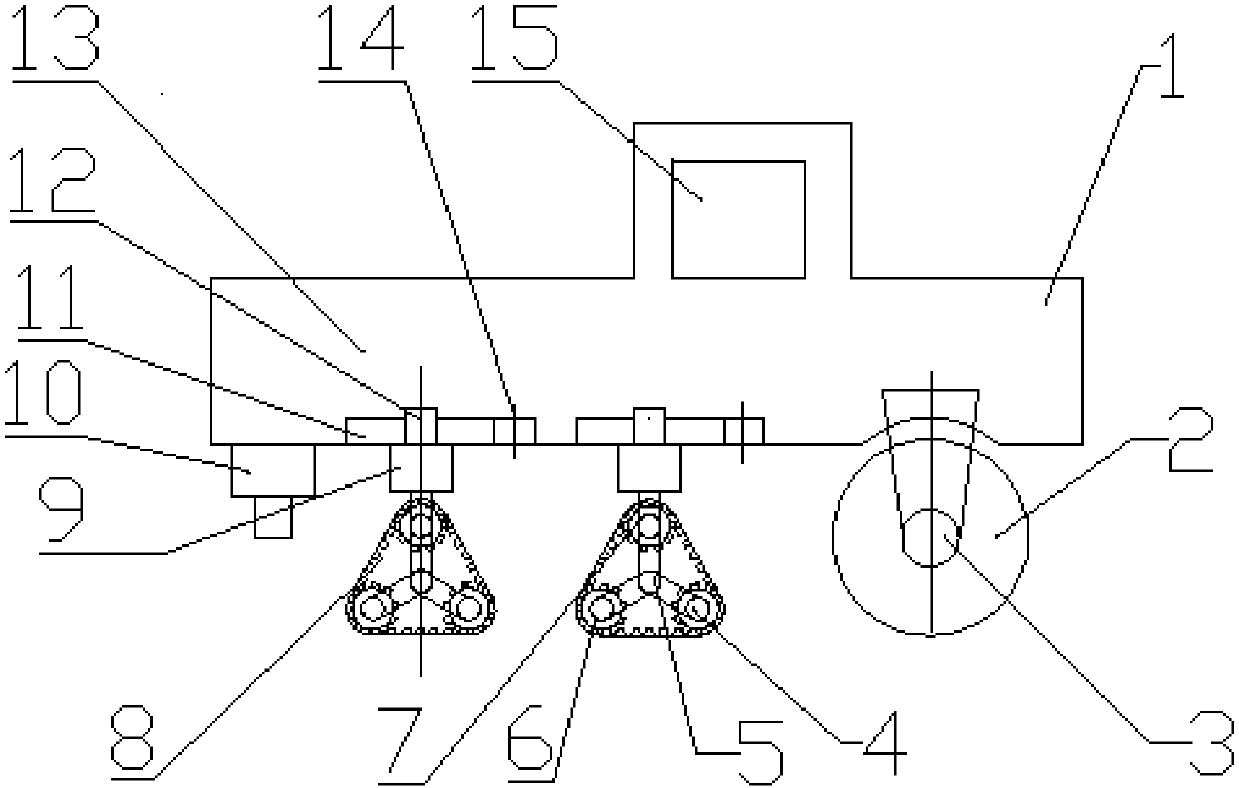

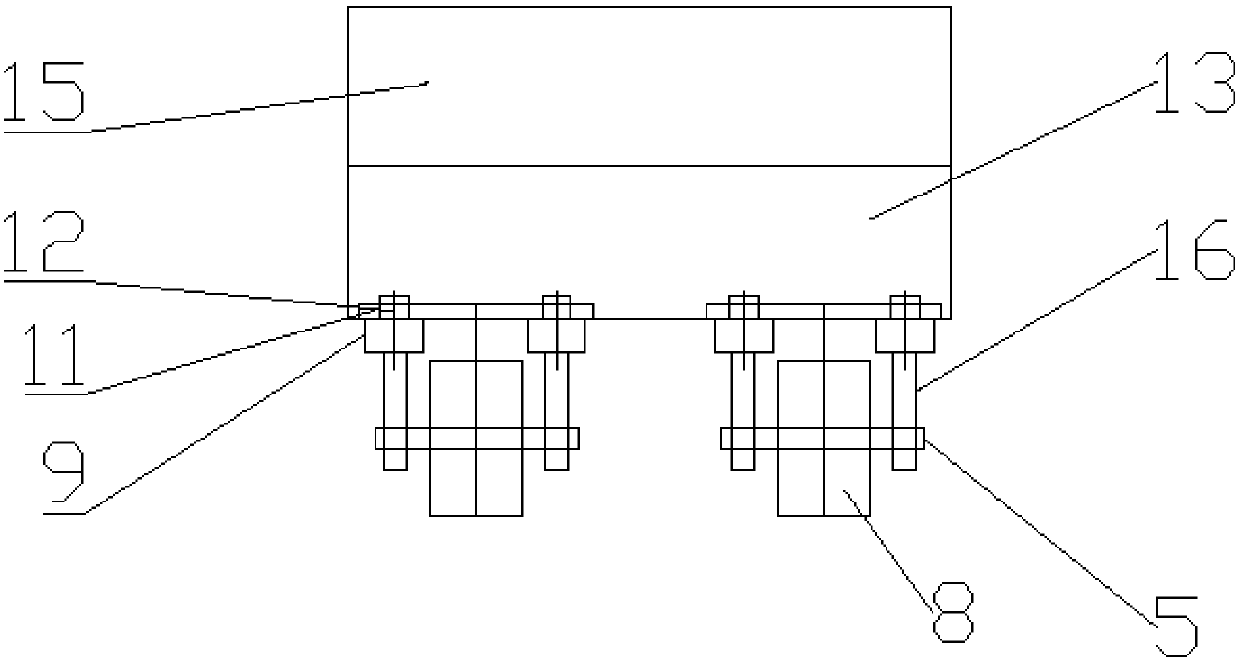

[0024] Below in conjunction with accompanying drawing, the present invention is described in further detail:

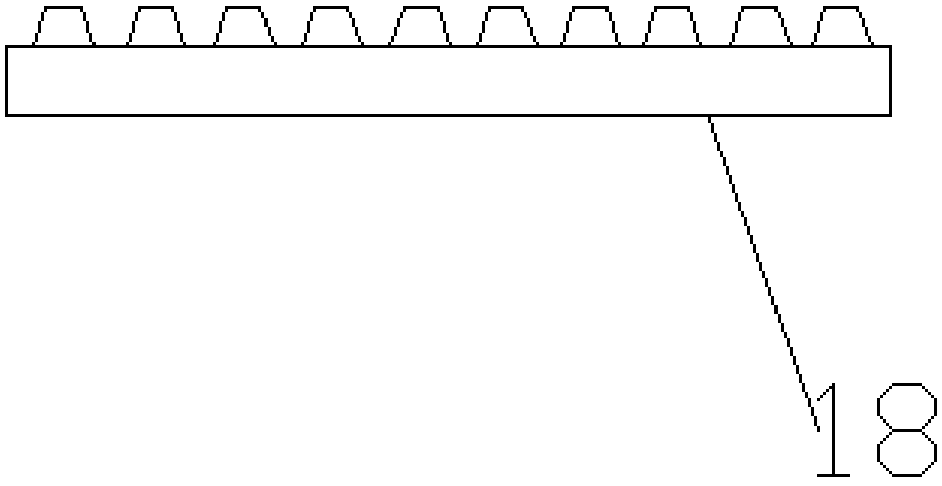

[0025] see Figure 1 to Figure 6 , a filling compaction device, comprising a road roller body 1, a vibrating wheel 2, and a crawler belt device 8, wherein the crawler belt device includes a crawler belt 18 meshed with a driving gear 6 equipped with a hydraulic motor 17, and the driving gear 6 rotates to drive the crawler belt through engagement 18 rotates, and then drives the first driven gear 4 and the second driven gear 7. The road roller body 1 includes a road roller body 13 and a driver's cab 15. There is a hydraulic support 10 at the bottom of the road roller case 13. When the road roller body 1 needs to turn in a wide range, the hydraulic support 10 falls and lands for support, and the crawler belt device 8 is suspended and turns. Landing slowly at the end, the hydraulic support 10 rises off the ground. The height of the crawler device 8 is controlled by the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com