Bubble atomizing goaf gas-liquid two-phase flow fire prevention and extinguishing system

A gas-liquid two-phase flow, anti-fire technology, applied in the direction of fire prevention, dust prevention, mining equipment, etc., can solve the problems of large gas consumption, atomization principle and atomization device introduction, nozzles are easy to block, etc., to achieve the spray angle And range improvement, improved fire prevention effect, simple and reliable system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

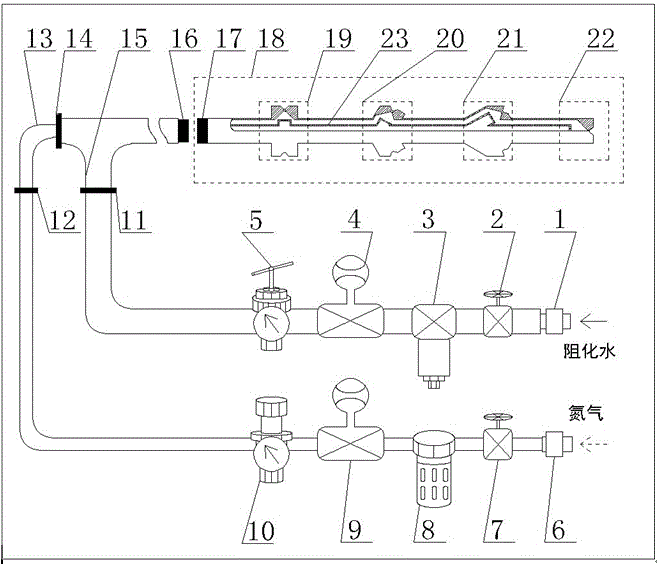

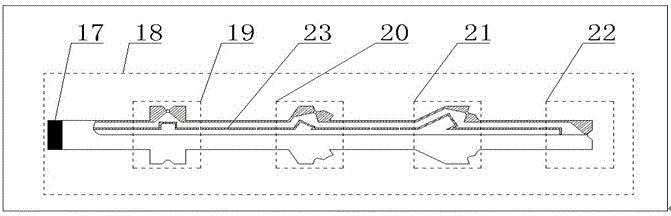

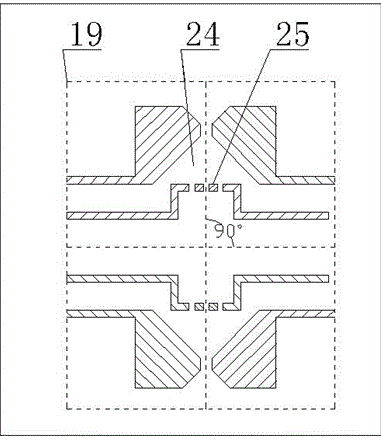

[0032] As shown in the accompanying drawings: a gas-liquid two-phase flow fire prevention system for bubble atomization gobs of the present invention consists of three parts: a gas-liquid parameter control and adjustment device, a gas-liquid delivery pipeline, and a gas-liquid two-phase flow three-dimensional nozzle device composition.

[0033] The working process of the gas-liquid two-phase flow fire extinguishing system of the bubble atomization goaf:

[0034] (1) Arrangement of piping and gas-liquid two-phase flow three-dimensional nozzle device. Both the nitrogen pipeline and the resistance water pipeline are arranged in the wind inlet groove of the working face; the gas-liquid two-phase flow three-dimensional nozzle device and the pre-processed embedded air pipe are connected through the nozzle outer wire joint 16 and the nozzle inner wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com