Rotor type compressor pump body

A compressor pump and rotor type technology, which is applied in the field of compressors, can solve the problems of low processing accuracy of the roller sliding vane receiving groove, and difficulty in ensuring the processing position of the groove, so as to achieve good processing technology, ensure processing quality, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

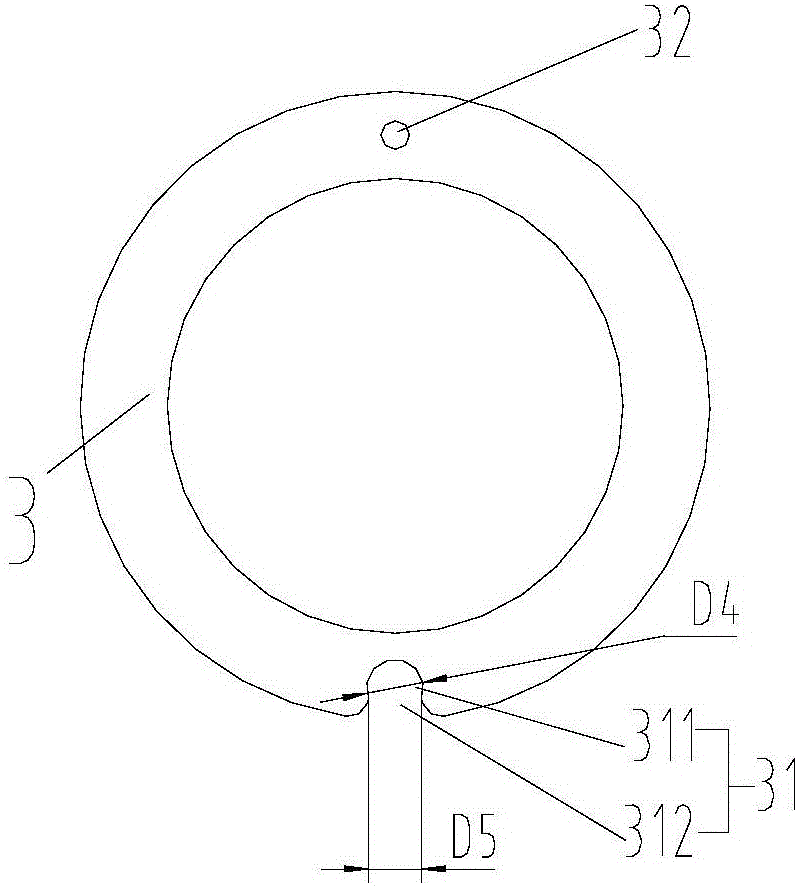

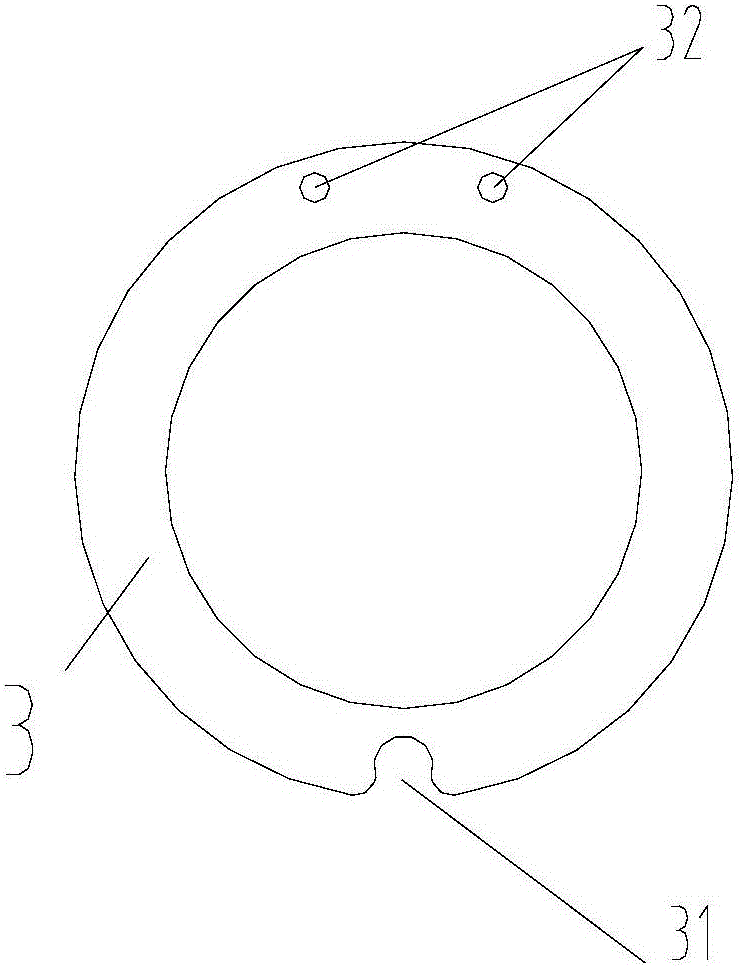

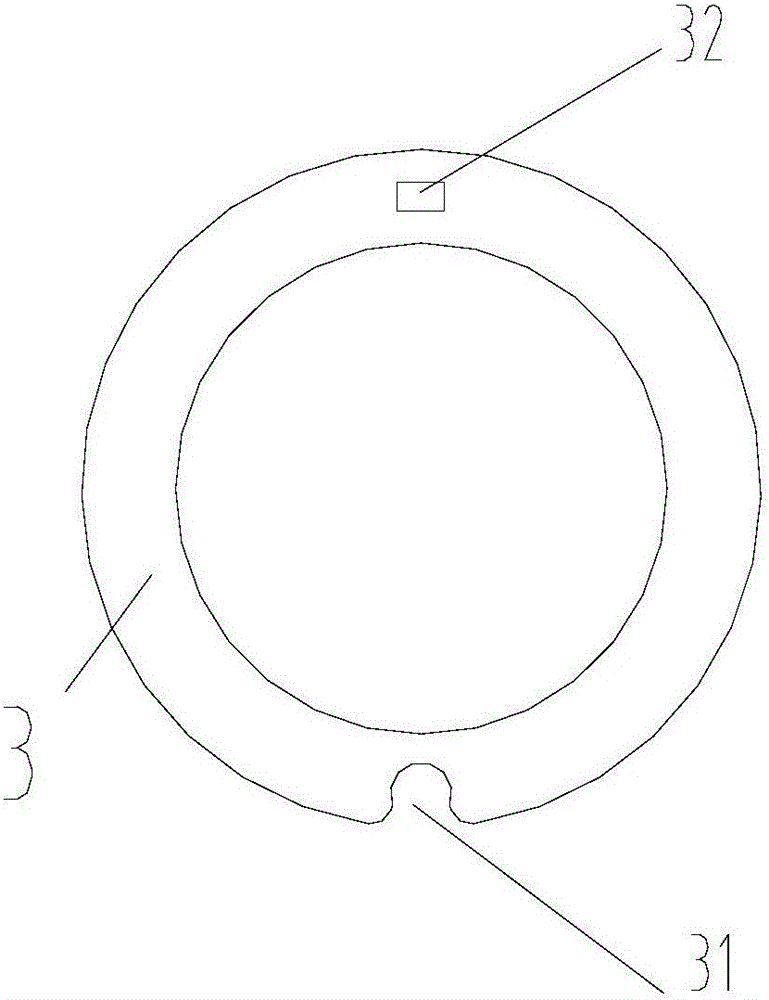

[0033] Such as Figure 1-4 , as shown in 8, the present invention provides a rotary compressor pump body, which includes a cylinder 1, a crankshaft 2, a roller 3 and a slide 4, the roller 3 is in the shape of a circular cylinder, wherein the roller 3 A slide receiving groove 31 that matches the shape of one end of the slide 4 and can accommodate the insertion of the end of the slide 4 is provided on the top (that is, a slide is provided at a position corresponding to and in contact with the slide 4 ). sheet accommodating groove 31), and on the other side of the slide sheet accommodating groove 31 relative to the center of the roller 3 on the roller 3, at least one processing hole 32 and / or at least one Process slot 33.

[0034] The pump body of the rotor type compressor of the present invention can accurately judge and locate the need to process and open the sliding vane accommodation by setting at least one processing technology hole and / or the structural form of the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com