Valve body structure of fuel system

A fuel system and valve body technology, which is applied in the valve shell structure, the valve's device for absorbing fluid energy, valve details, etc., can solve the problems of diaphragm resonance prone to abnormal noise, different performance, and small valve body flow. Achieve the effect of easy batch realization, convenient processing, and avoidance of resonance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

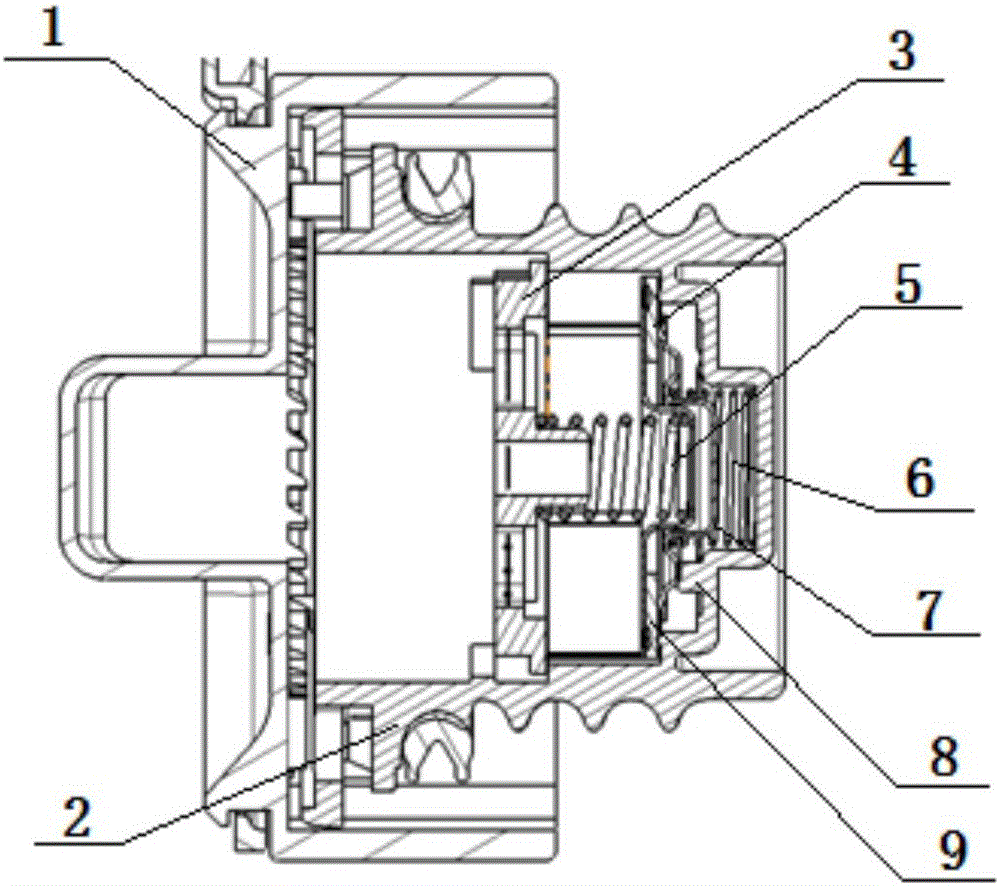

[0015] The present invention is a structure that can effectively relieve the abnormal sound of the valve body of the fuel system under specific negative pressure conditions. The valve body includes a valve body knob 1, a valve body base 2, a filter cover 3, a positive pressure gasket 4, a Compression spring 5, negative pressure spring 6, negative pressure gasket 7, support seat 8 and diaphragm 9.

[0016] The valve body base 2 is a hollow structure, one end of the valve body base 2 is covered with a valve body knob 1 , the other end of the valve body base 2 is provided with a support seat 8 inside, and the other end is provided with an external thread. The integral injection molding of the valve body base 2 and the support seat 8 makes the structure more stable and reliable, and also reduces the production cost.

[0017] The valve body base 2 is provided with a filter cover plate 3, one end of the positive pressure spring 5 is fixed on the convex column in the center of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com