Spigot-and-socket pipeline interface deformation measurement apparatus and measurement method based on distributed fiber strain sensor

A distributed optical fiber and strain sensor technology, applied in measurement devices, optical devices, instruments, etc., can solve the problems of weak optical fiber tension, reduced optical fiber availability and accuracy, optical fiber breakage, etc. Convenience, simple structure and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions implemented by the present invention will be described in detail and completely below in conjunction with the accompanying drawings.

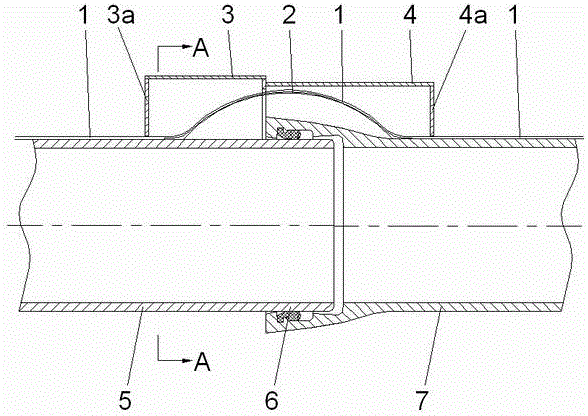

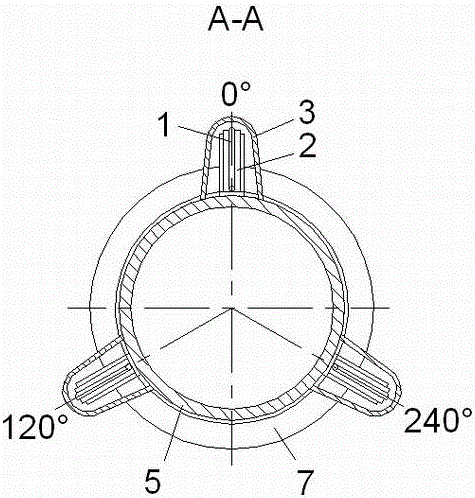

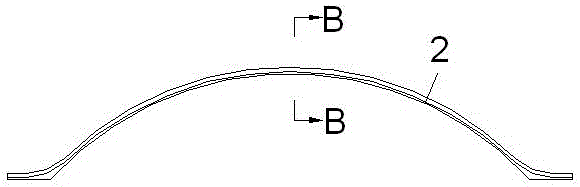

[0046] figure 1 , 2 A structural diagram of a socket-type pipe joint deformation measuring device is shown. In the figure, the socket-type pipe interface deformation measurement device based on the distributed optical fiber strain sensor includes a socket-type pipe insertion head 5, a T-shaped sealing rubber ring 6, a socket-type pipe socket plug 7, three distributed optical fibers 1 and three A bow-shaped measuring device 2, a T-shaped sealing rubber ring 6 is placed in the sealing groove in the socket-type pipe socket plug 7, and then inserted into the socket-type pipe insert head 5. Three bow-shaped measuring devices 2 are evenly distributed around the socket-type pipe joint, one end of the bow-shaped measuring device 2 is fixed on the outer wall of the socket-type pipe insertion head 5 with glue, and the oth...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap