Method for testing homogeneous control effect in threshing and redrying process

A technology of threshing, redrying, and homogenization, which is applied in measurement devices, color/spectral property measurement, material analysis by optical means, etc., can solve the problems of lack of practicability and lack of evaluation effect, and achieve strong stability. , strong systemic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention is further set forth below in conjunction with embodiment. It should be understood that the examples are only used to illustrate the present invention, not to limit the scope of the present invention.

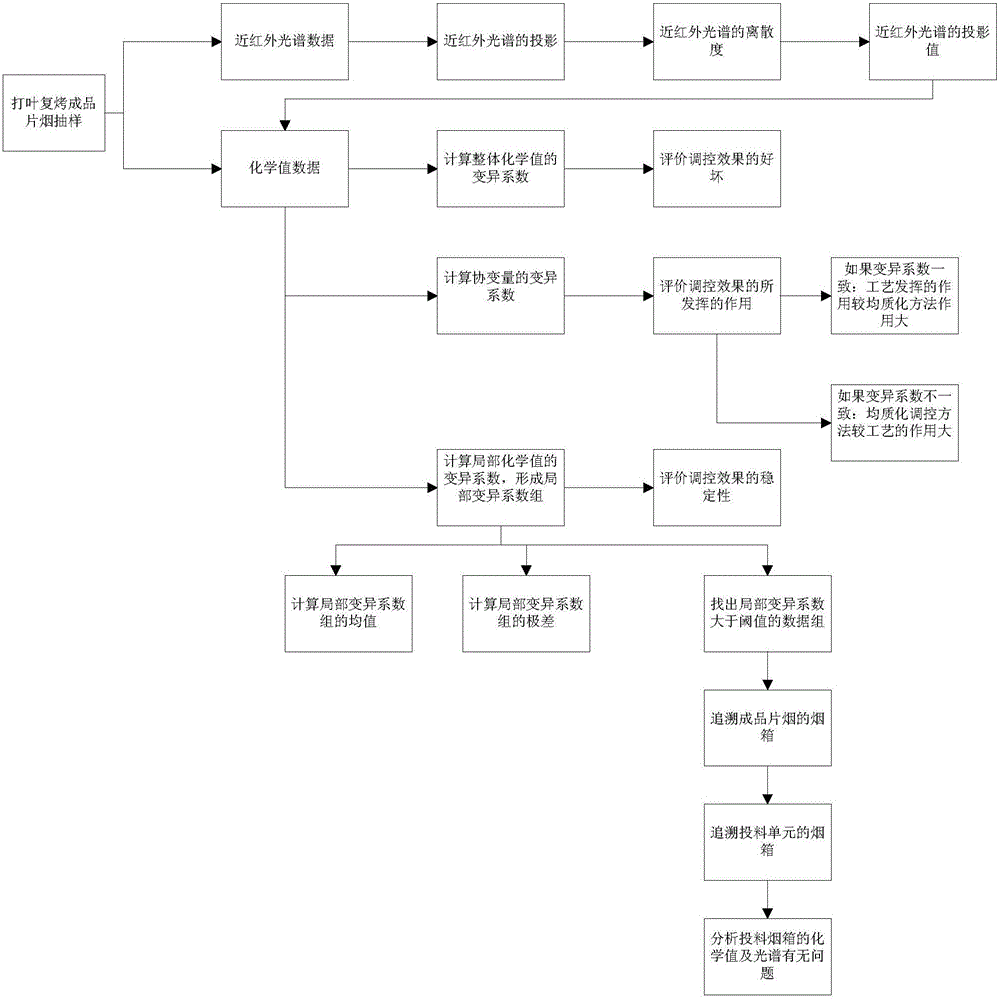

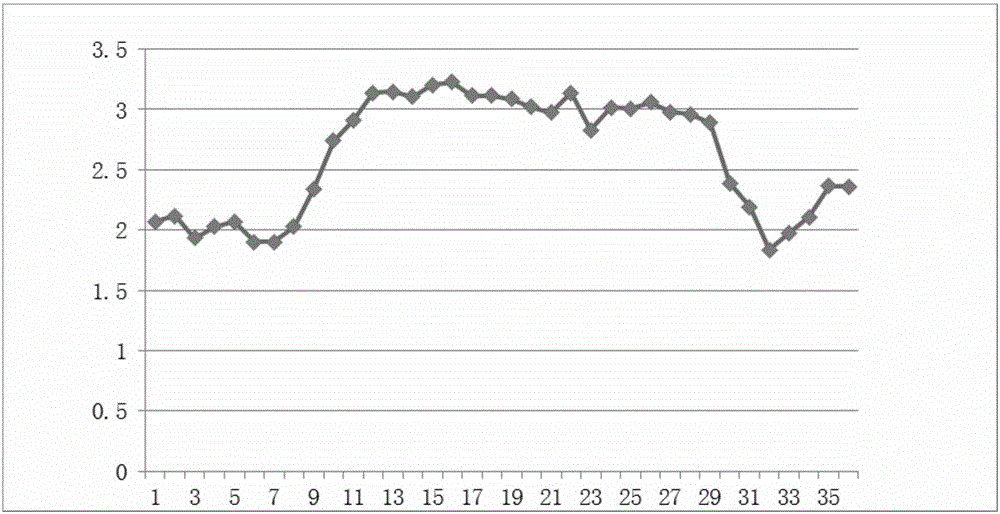

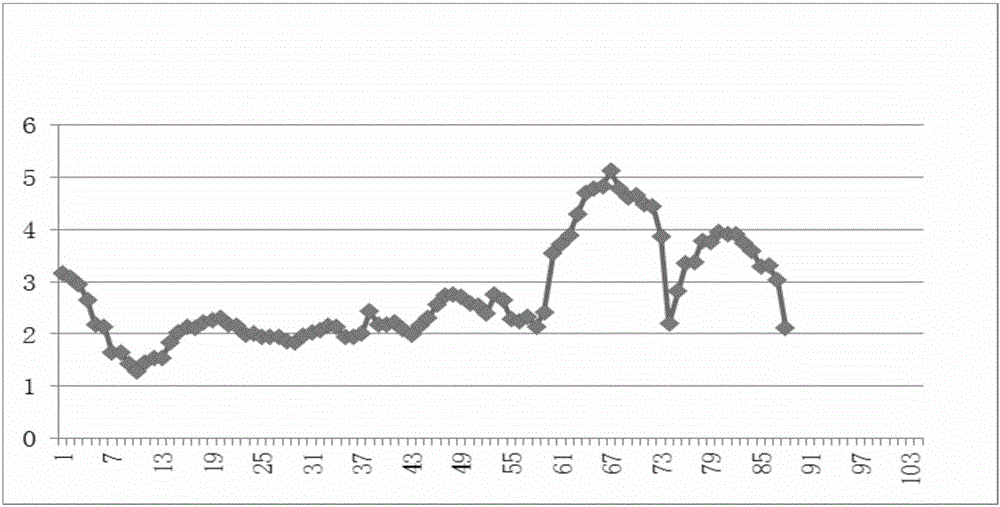

[0037] see figure 1 , the invention discloses a method for testing the homogenization process of finished tobacco sheets obtained by threshing and redrying, which is used to detect and evaluate the effect of the homogenization method adopted in the threshing and redrying process on certain The homogenization effect of a chemical composition. It first samples the finished tobacco sheets that have been regulated by the threshing and redrying process and the homogenization method according to the order of boxing on the production line, and marks them as the first sample, the second sample,... , the i-th sample, ..., the n-th sample. The n samples are tested by near-infrared spectroscopy to obtain the chemical values of the corresponding chemical c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com