A fast covering plate for curing furnace mouth of coloring machine

A technology of curing furnace and covering plate, which is applied in the direction of fiber mechanical structure, instrument, optics, etc. It can solve the problems affecting the degree of curing of optical cables, the impact of production process, and the impact of production efficiency, so as to improve the coloring quality, good sealing effect and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below through specific examples. The following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

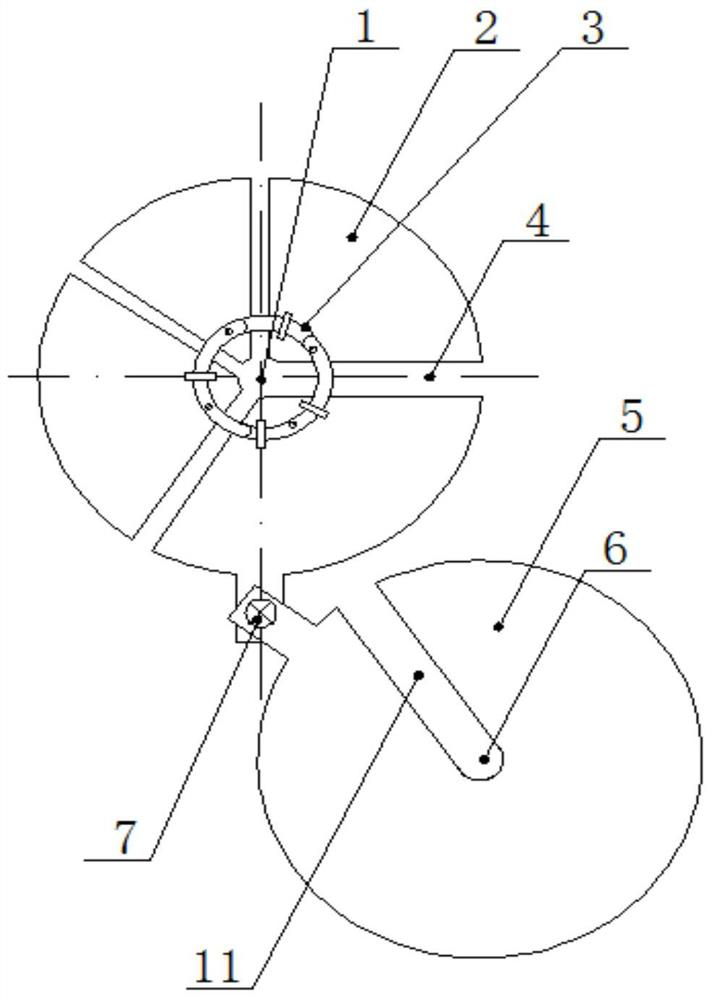

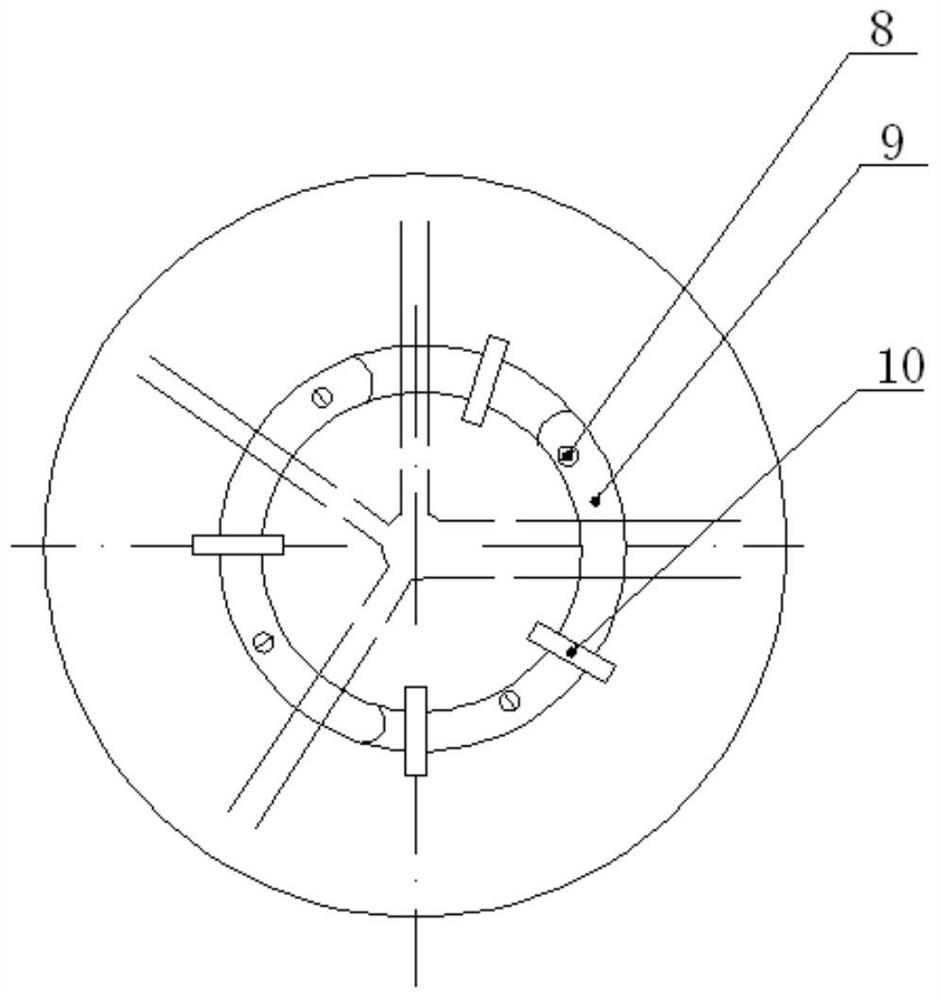

[0023] like figure 1 As shown, a kind of quick cover plate for the curing furnace mouth of the coloring machine is composed of a lower bottom plate 2, an upper cover plate 5 and a ring buckle structure 3, and the lower bottom plate and the upper cover plate are two circular plates with the same diameter, One end of the two circular plates is correspondingly formed with a connecting part, and the corresponding connecting parts of the lower bottom plate and the upper cover plate are hingedly mounted by screws 7 . The ring buckle structure is concentrically installed on the center of the upper surface of the lower bottom plate. In the ring buckle structure, a circular hole groove 1 is concentrically opened in the center of the lower bottom plate, and the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com