Backlight detecting mold

A backlight detection and mold technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of inconvenient use, small light-transmitting area, and high cost, saving mold space, avoiding frequent replacement, and effectively covering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

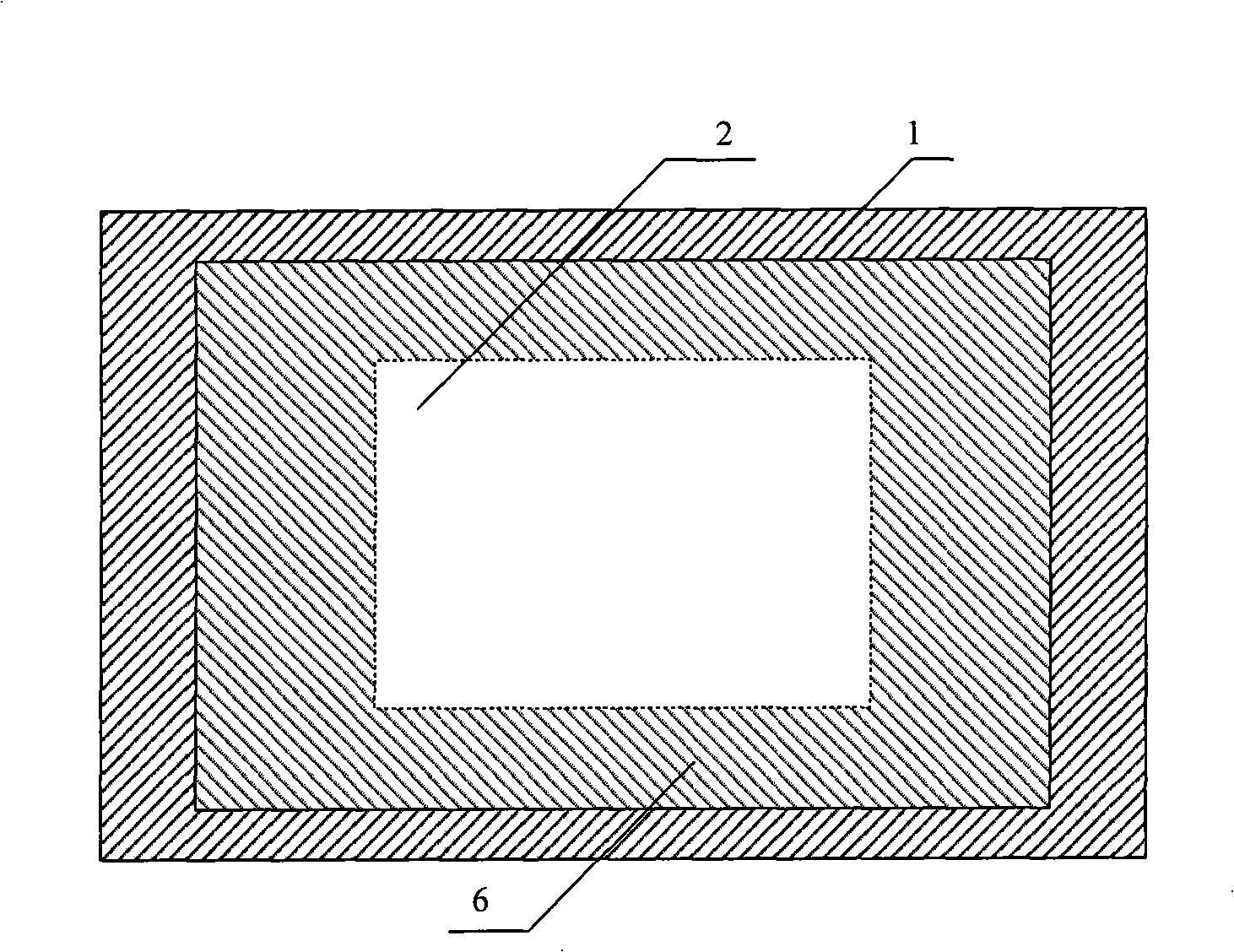

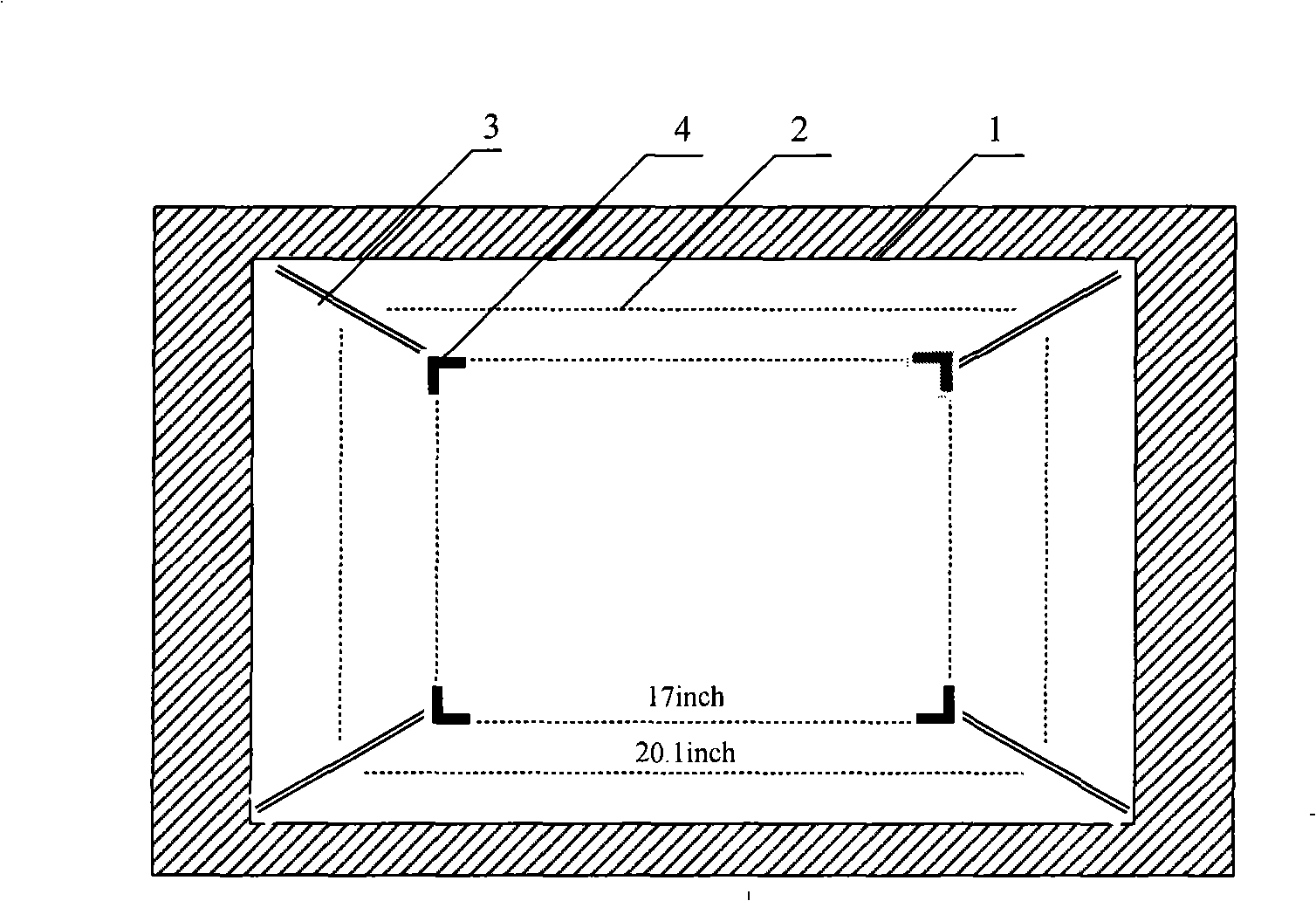

[0020] Such as image 3 , 4 , 5, the backlight detection mold includes a frame 1, a detection base plate 2, a hole 3, a clamp block 4, and a blocking sheet 5. The detection base plate 2 is embedded in the frame 1, and a section of hole 3 is opened on the detection base plate 2 along a diagonal line from four apexes to the center of the detection base plate 2, and a clamping block 4 is slid on the hole 3, and the clamping block 4 is on the hole 3 Slide, and fix on the hole 3 by clamping the upper and lower parts of the clamp block 4; there is also a gasket on the clamp block 4, which is used to resist the screen under test, so that the screen under test is placed on the detection base plate 2 relatively stably superior. The detection bottom plate is made of transparent material acrylic; the detection bottom plate 2 is provided with a size mark showing the measured area.

[0021] When testing, for example, first detect the 17inch TFT-LCD, such as Figure 4 As shown, first sl...

Embodiment 2

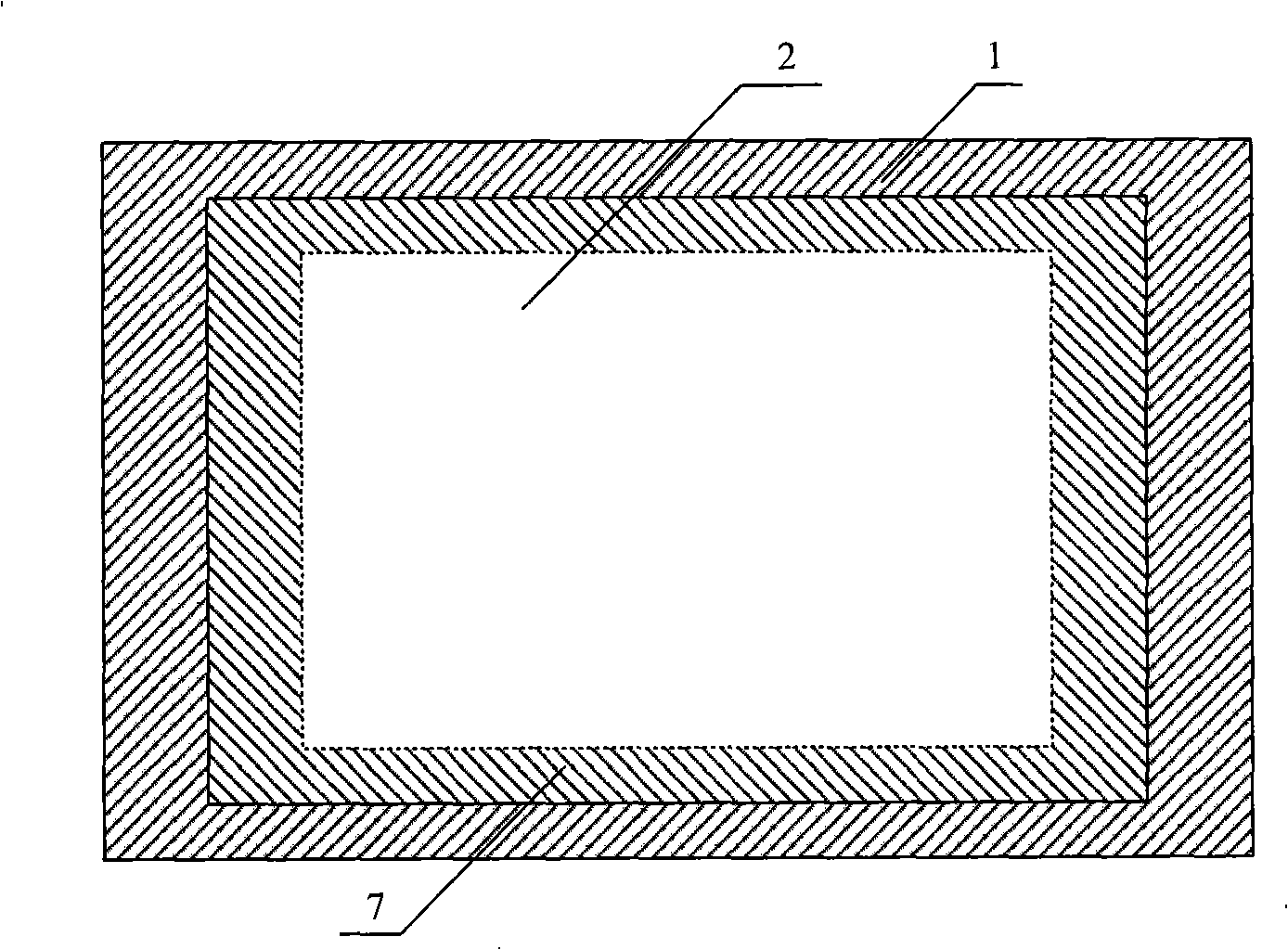

[0023] Based on Embodiment 1, the shielding sheet 5' is rolled into the frame 1, the shielding sheet 5' is connected to the clamping block 4, and can move together with the clamping block 4, and the shielding sheet 5' extends outward when the clamping block 4 moves outward , when the clamp block 4 moves inward, the blocking piece 5' retracts inwardly, covering the part of the detection base plate 2 that is not covered by the screen under test in a manner of advancing and retreating at the same time; logo.

[0024] When testing, for example, first check the 20.1inch TFT-LCD, such as Figure 6 As shown, slide the clamp block 4 on the place marked with a size of 20.1 inches, and place the TFT-LCD under test on the detection base plate 2. At this time, the gasket on the clamp block 4 has been pressed against the TFT-LCD under test, so that Its fixation will not shift left or right or up and down; and because the shielding piece 5' is connected with the clamp block 4, the exposed ...

Embodiment 3

[0026] Based on Embodiment 1 or 2, 2 or more holes can be opened in different positions of the detection base plate as required, and clamp blocks can be slid on the holes to meet the requirements of fixing the screen under test. For example, two holes can be opened on the detection base plate, and clamping blocks can be slid on the holes. If the method of forming a certain angle with the horizontal plane is adopted during the image quality inspection, at least one hole may be provided at the lower edge of the inspection base plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com