Method for realizing beam tight focusing through vortex beams

A vortex beam, tight focusing technology, applied in optics, optical components, instruments, etc., can solve the problem of focusing spot numerical aperture and light wavelength limitation that cannot obtain focusing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0026] Specific Embodiment 1: A method of using a vortex beam to achieve tight beam focusing in this embodiment is specifically prepared according to the following steps:

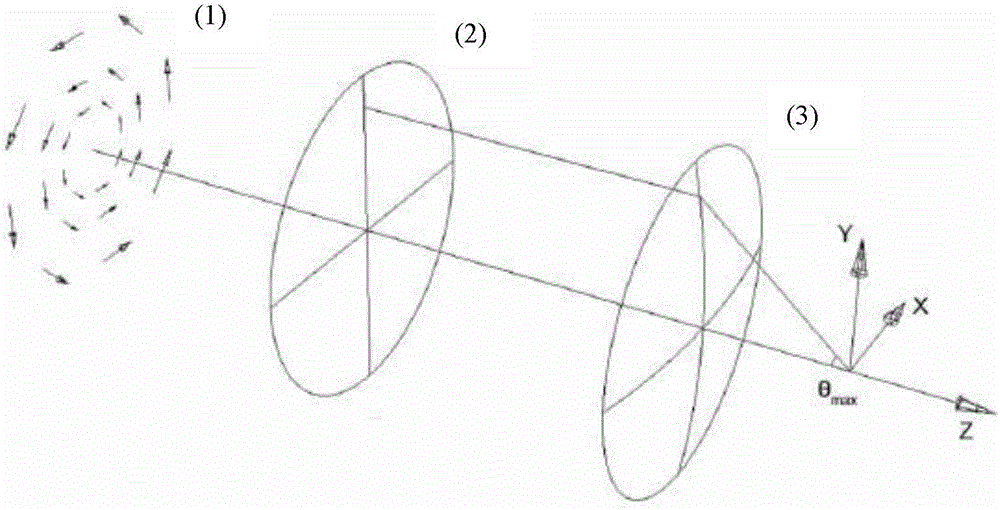

[0027] The device for realizing tight focusing of beams by using vortex beams specifically includes an azimuthal polarizer, a 0-2π spiral phase plate (VPP-1c) and a high numerical aperture focusing lens such as figure 1 (GCL-010213);

[0028] Step 1, making the azimuthal polarized light incident on the helical phase plate;

[0029] Step 2, using the spiral phase plate to linearly modulate the phase of the azimuthally polarized light according to the angular orientation in the range of 0 to 2π, thereby completing spatial phase encoding to form a vortex beam;

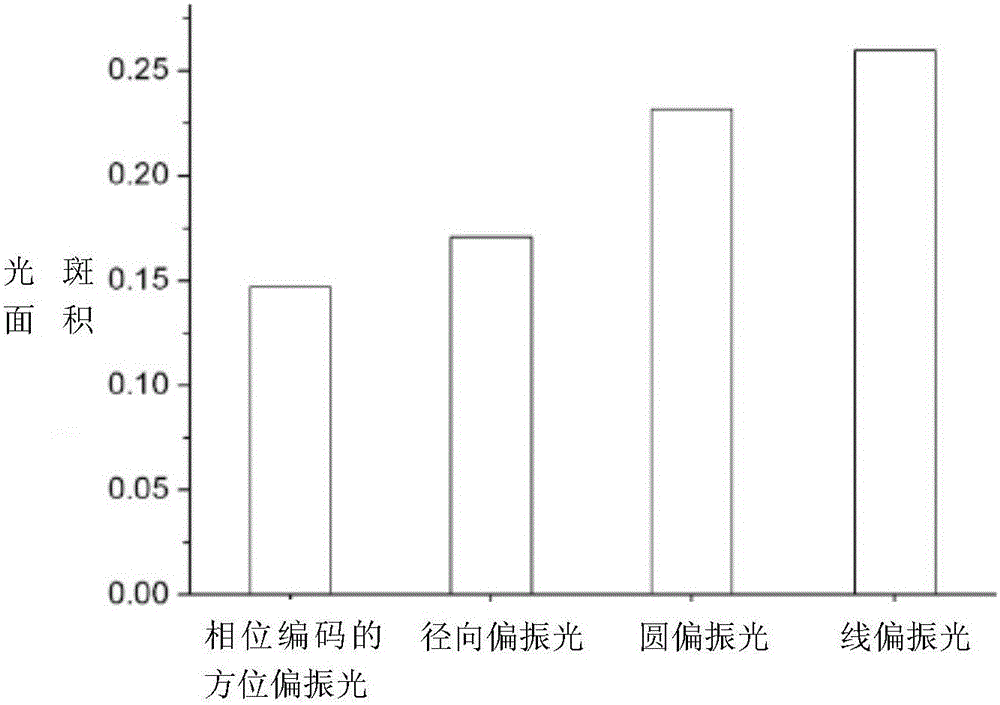

[0030] Step 3. Let the vortex beam with known phase encoding pass through the aperture focusing lens to form a focused spot that is better than the Rayleigh diffraction limit;

[0031] The general idea is that polarized light and phase-encoded light...

specific Embodiment approach 2

[0053] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that in step 2, the phase of azimuthally polarized light is controlled by a spiral phase plate in the angular direction Linear modulation is performed in the interval. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

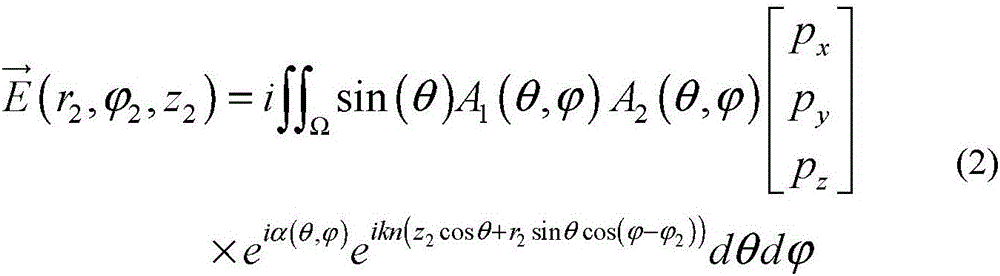

[0054] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the specific process of phase encoding in step 2 to form a vortex beam is as follows:

[0055] The electric vector of incident azimuthally polarized light is After passing through the spiral phase plate, the electric vector for:

[0056]

[0057] In the formula: is the azimuth coordinate function; e is the exponential function;

[0058] From the above formula, it can be seen that the phase distribution on the cross-section of the beam changes with the radial angle, which has vortex characteristics; making azimuthally polarized light into a vortex beam. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com