Multi-model Fractional Order Weighted Predictive Function Control Method for Electric Heating Furnace

A control method and weighted prediction technology, applied in the field of automation, can solve the problems of difficult to achieve modeling accuracy of nonlinear systems, hindering the development of controllers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The main idea of the present invention is to divide the entire working area into several sub-areas according to a certain method, and establish a corresponding fractional order model in each sub-area and control it in combination with a predictive function. Therefore, the original nonlinear model is converted into a linear fractional order model, the accuracy of the model avoids the complexity of nonlinearity, and effectively solves the problem of low model accuracy in industrial engineering that affects product quality. The specific steps are:

[0066] 1 Establish the multi-model structure of the electric heating furnace.

[0067] 1.1 According to the working temperature range of the electric heating furnace, the working area is divided into i equal parts, and i is the number to be divided into equal parts.

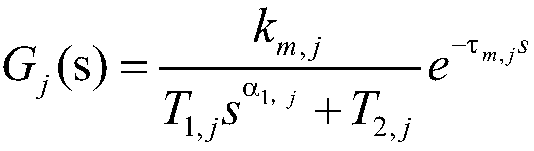

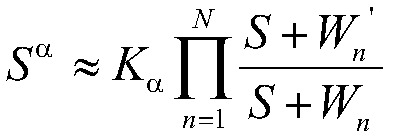

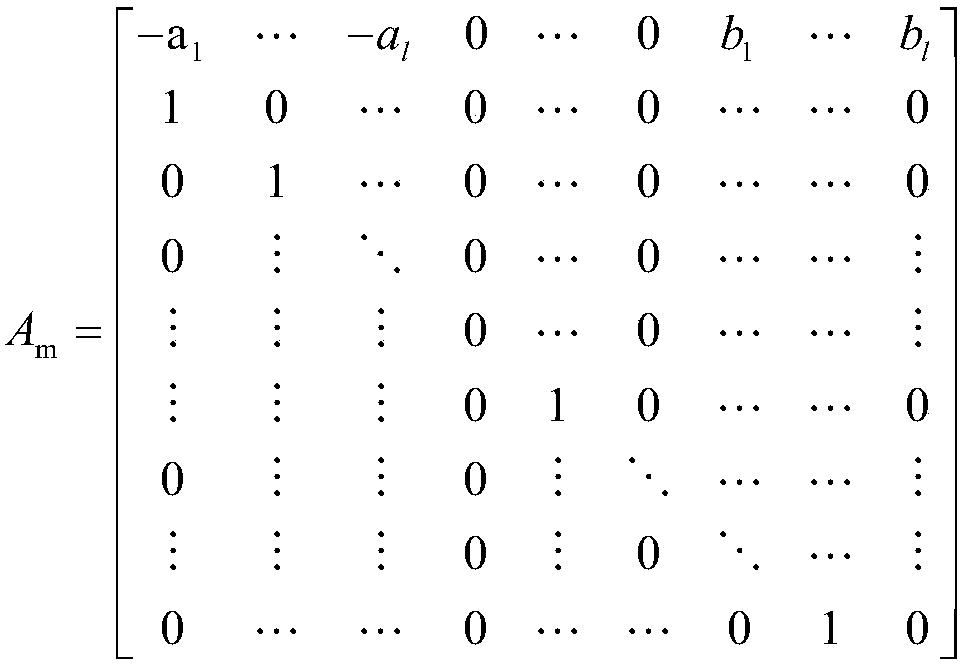

[0068] 1.2 Collect the real-time step response data of the electric heating furnace in each equally divided interval, and use the data to establish the fractio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com