Segmented cage and roller bearing

A technology of roller bearings and cages, applied in the direction of roller bearings, shafts and bearings, rolling contact bearings, etc., to achieve the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

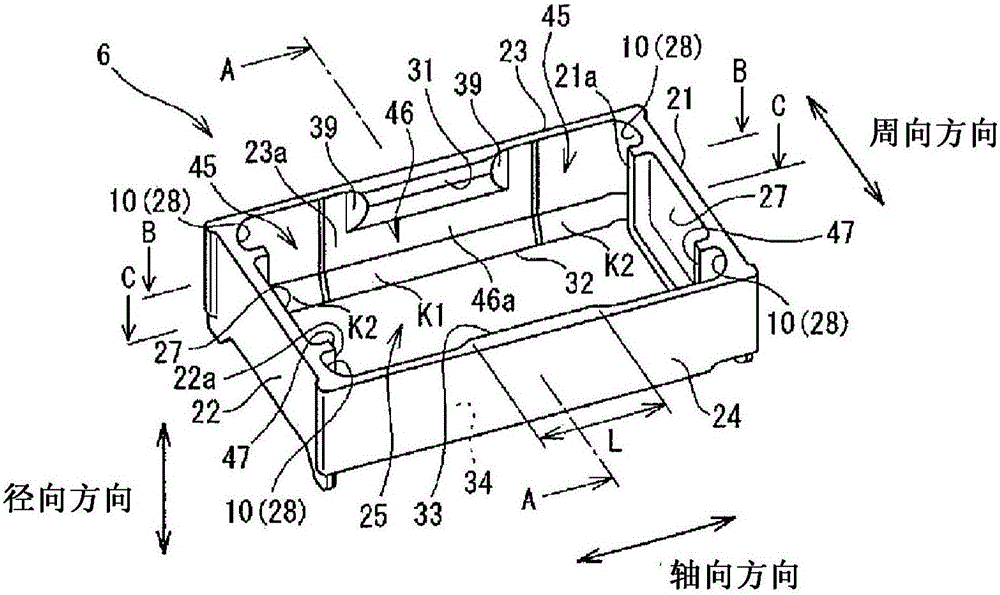

[0078] Embodiments of the present invention will be described below with reference to the drawings.

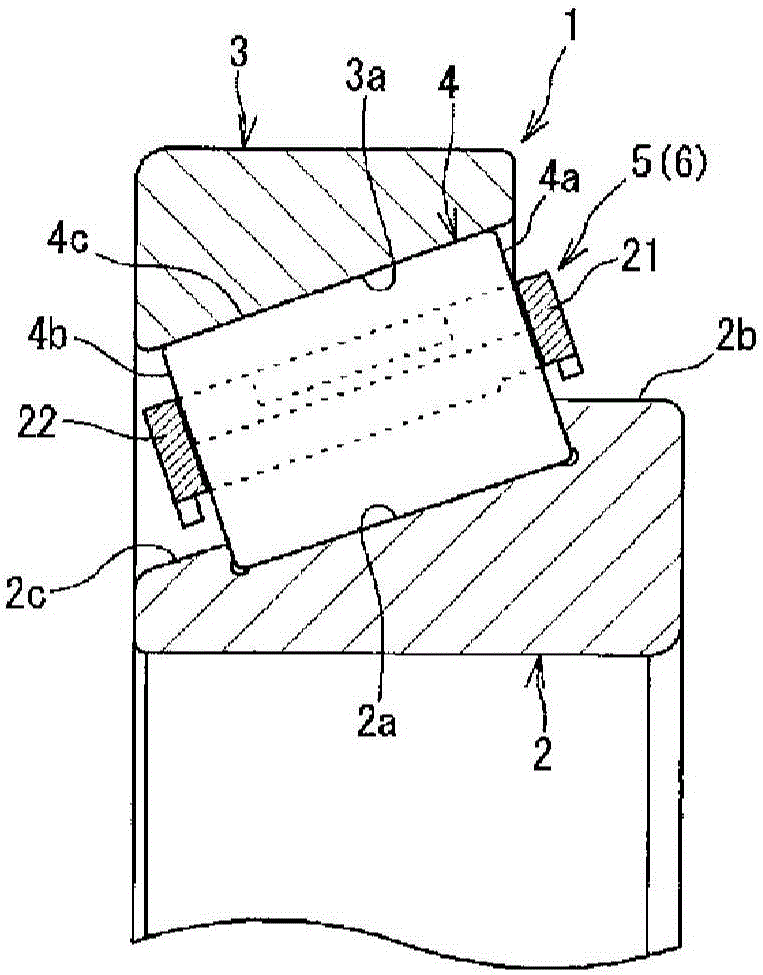

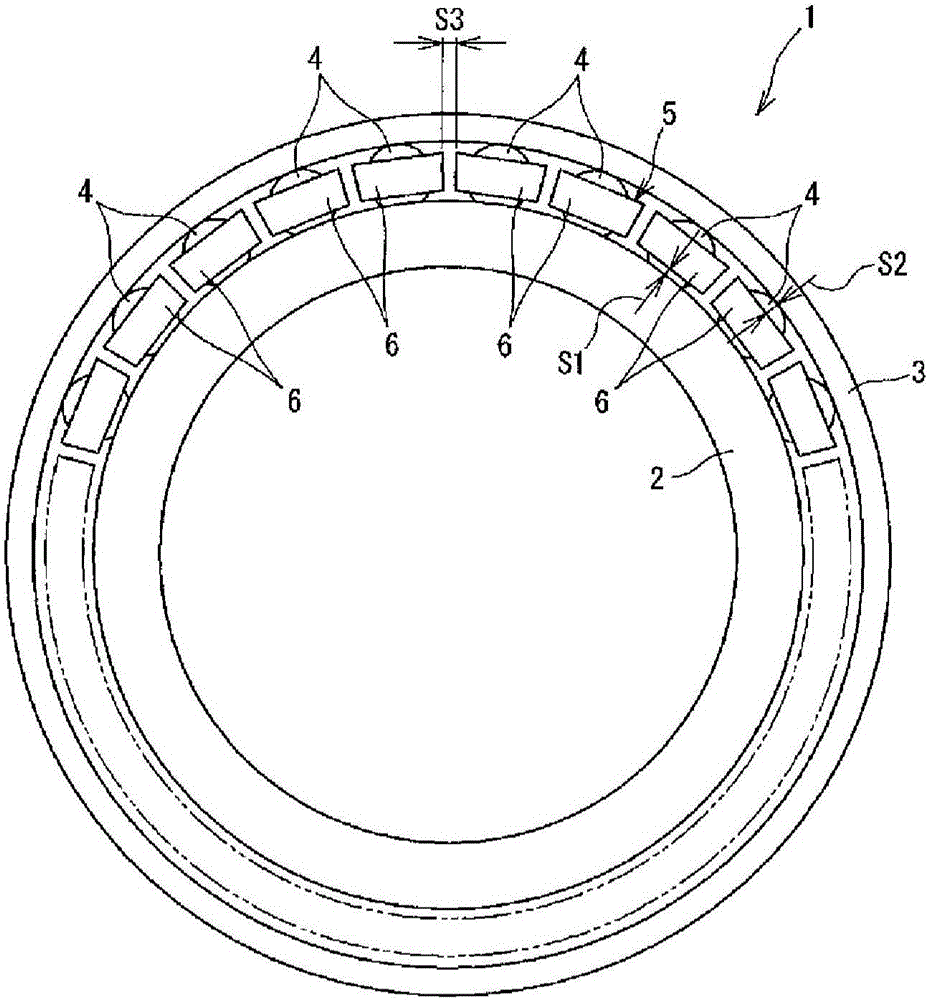

[0079] figure 1 is a main part sectional view showing a roller bearing provided with a cage according to the present invention. figure 2 is a side view showing the roller bearing. The roller bearing 1 according to this embodiment is a tapered roller bearing comprising an inner ring 2, an outer ring 3, a plurality of tapered rollers rollably arranged in an annular space between the inner ring 2 and the outer ring 3 4 and the cage 5 holding the tapered roller 4. The cage 5 according to this embodiment is a divided cage having a plurality of cage segments 6 . The inner ring 2, the outer ring 3 and the tapered rollers 4 are made of steel such as bearing steel.

[0080] exist figure 1 Among them, in the inner periphery of the outer ring 3, an outer ring raceway surface 3a made of a tapered surface is formed so that the tapered rollers 4 can roll on the outer ring raceway surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com