Base cloth for filtering material and production method of base cloth

A filter material and production method technology, applied in the direction of filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problems of shortened service life of the base cloth, low strength of the base cloth, and reduced service life, so as to reduce the air resistance, reduce the The effect of weight and life extension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

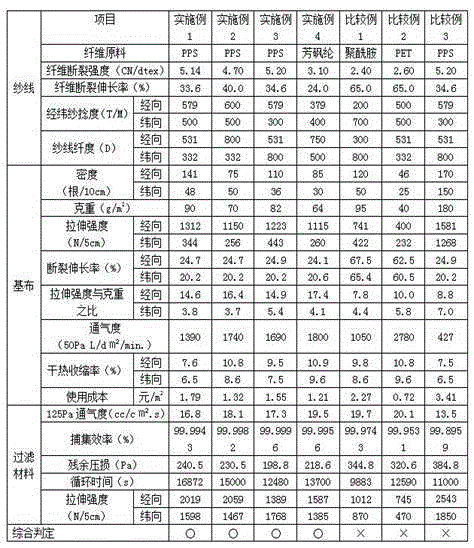

Embodiment 1

[0033] Spin PPS staple fibers with a breaking strength of 5.14CN / dtex, use a 4g warp-stop sheet, and use 2 pieces per reed to draw on the hedging machine to obtain a fineness of 531D and a twist of 579T / M The double-ply yarn is used as the warp yarn, and the single yarn with a denier of 332D and a twist of 500T / M is used as the weft yarn, and the above-mentioned PPS yarn is processed once at a temperature of 90°C, a humidity of 80%, and a time of 15 minutes. Heat setting processing, and then weaving the PPS yarn after heat setting processing with plain weave. When weaving, strictly control the warp density to 141 threads / 10cm, the weft density to 48 threads / 10cm, and finally obtain a grammage of 90g / m 2 , The warp direction tensile strength is 1312N / 5cm, the weft direction tensile strength is 344N / 5cm base fabric. See Table 1 for evaluating the physical properties of the base cloth of the present invention.

Embodiment 2

[0035] The PPS short fiber with breaking strength of 4.70CN / dtex is spun, the quality is 6g, and the number of piercings per reed is 3, and the threading machine is carried out to obtain a fineness of 800D and a twist of 600T / M The double-ply yarn is used as the warp yarn, the double-ply yarn with a denier of 332D and a twist of 500T / M is used as a weft yarn, and the above-mentioned PPS yarn is prepared at a temperature of 80°C, a humidity of 85%, and a time of 10min. 2 times of heat setting processing, and then the PPS yarn after the heat setting processing is woven with a plain weave. When weaving, the warp density is strictly controlled to be 75 threads / 10cm, and the weft density is 50 threads / 10cm. Weight is 70g / m 2 , The warp tensile strength is 1150N / 5cm, the weft tensile strength is 256N / 5cm base fabric. See Table 1 for evaluating the physical properties of the base cloth of the present invention.

Embodiment 3

[0037] The PPS short fiber with breaking strength of 5.20CN / dtex is spun, the quality is 7g, and the number of piercings per reed is 4, and the threading machine is carried out to obtain a fineness of 531D and a twist of 579T / M The double-ply yarn is used as the warp yarn, and the single yarn with a denier of 800D and a twist of 300T / M is used as the weft yarn, and the above-mentioned PPS yarn is carried out at a temperature of 95°C, a humidity of 80%, and a time of 15min. Carry out heat setting processing, and then weave the PPS yarn after heat setting processing with plain weave. When weaving, strictly control the warp density to 110 threads / 10cm, and the weft density to 36 threads / 10cm, and finally obtain the grammage 82g / m 2 , The warp direction tensile strength is 1223N / 5cm, the weft direction tensile strength is 443N / 5cm base fabric. See Table 1 for evaluating the physical properties of the base cloth of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com