A kind of regeneration method of organic oxide catalytic conversion to aromatics catalyst

A technology of organic oxides and catalytic conversion, which is applied in the direction of catalyst regeneration/reactivation, physical/chemical process catalysts, chemical instruments and methods, etc. It can solve the difficulties in the facade layout of reactors and regenerators, the increase of main air outlet pressure, To solve the problem of high dense bed height, to ensure the burning time and burning effect, reduce the outlet pressure and increase the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

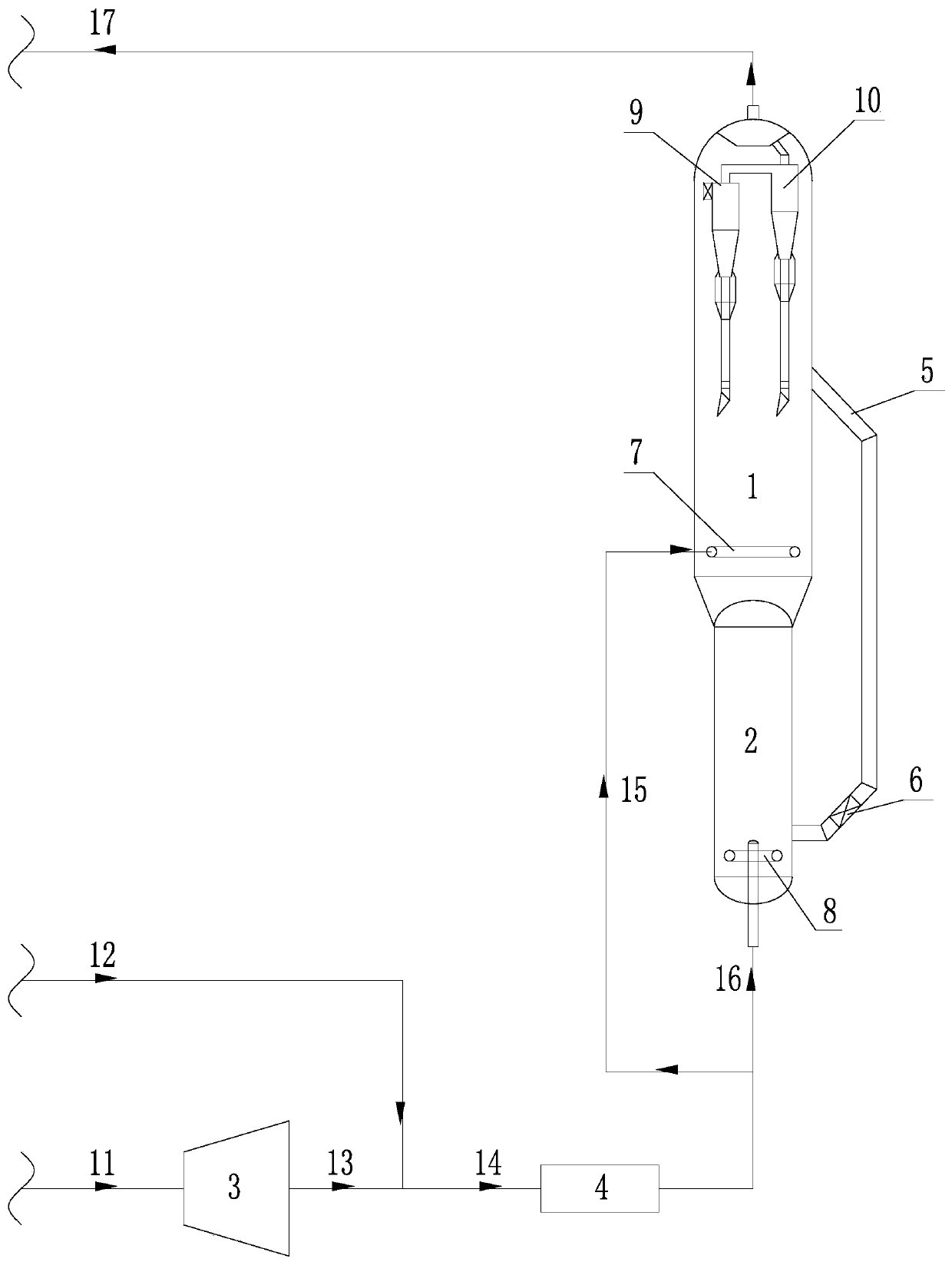

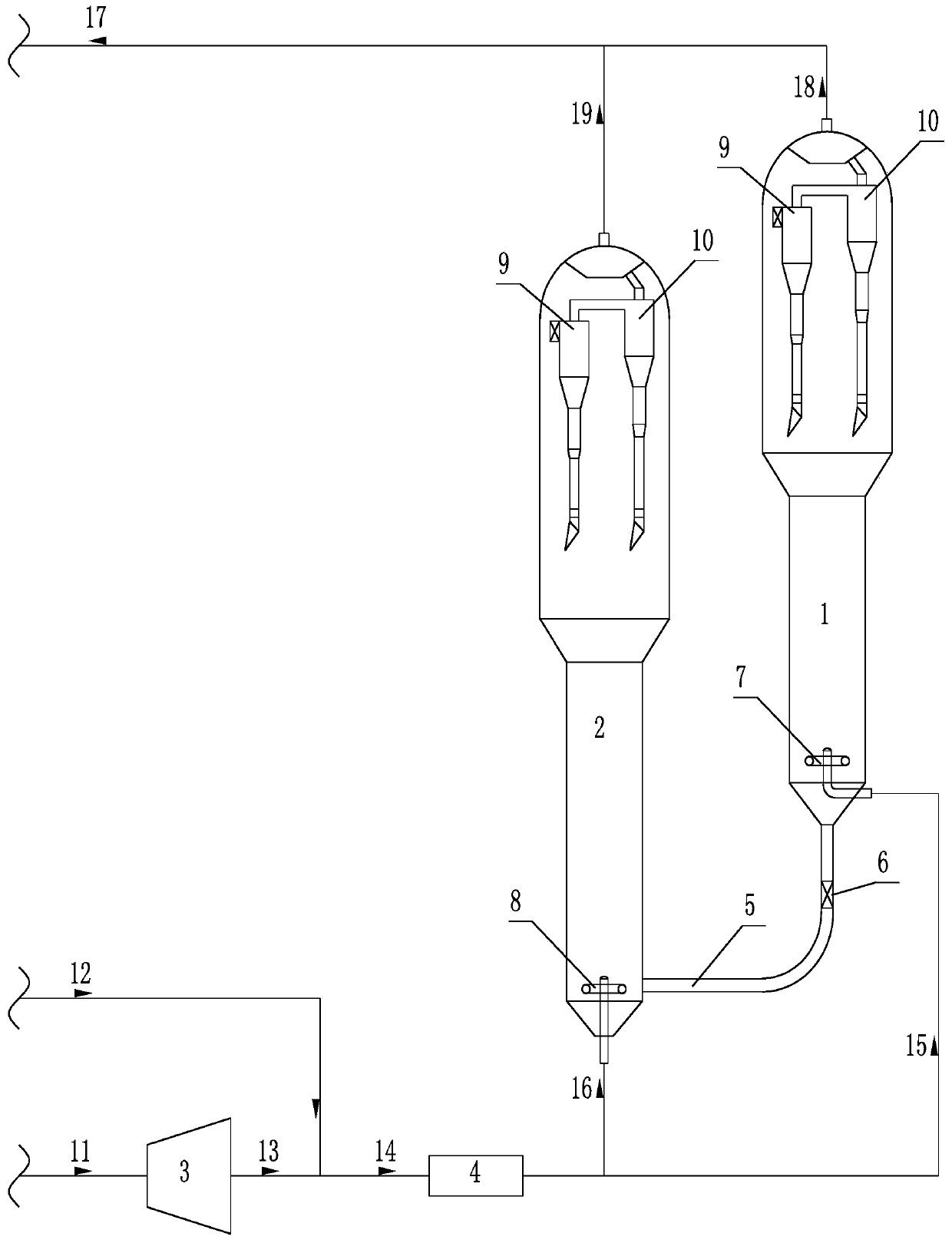

[0040] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0041] The present invention provides a method for regenerating catalysts for catalytic conversion of organic oxides to aromatics, the method comprising: sending the spent catalyst from the reaction system for catalytic conversion of organic oxides to aromatics into a first regenerator to contact with an oxygen-deficient main air and Carry out the first regeneration to obtain the semi-regenerated catalyst and the first regenerated flue gas; send the semi-regenerated catalyst into the second regenerator to contact with the second oxygen-depleted main air and perform the second regeneration to obtain the regenerated catalyst and the second regenerated flue gas ; T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com