A finishing system for PE liner tank mouth

A can opening and liner technology, applied in the field of PE can opening trimming system, can solve the problems of large manual operation error, slow speed and high error rate, and achieve the effect of avoiding vibration displacement, fast speed and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below with reference to the accompanying drawings and embodiments.

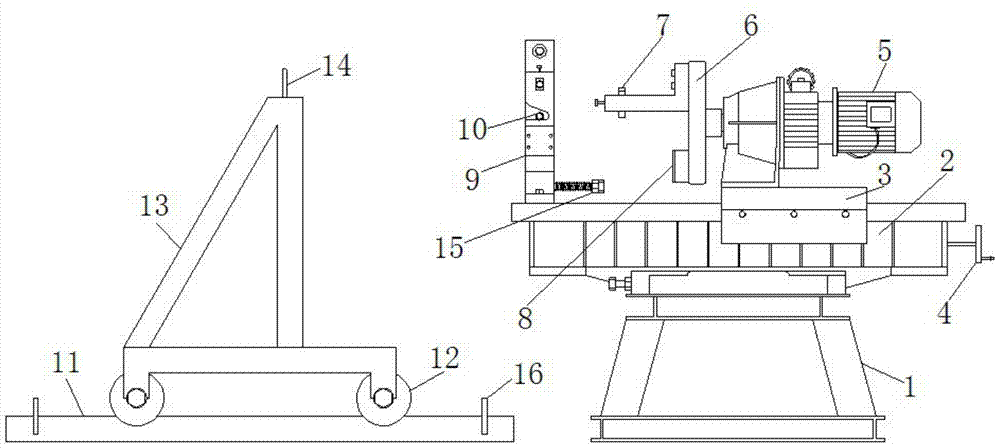

[0011] like figure 1 As shown, a PE inner tank finish system according to the present invention includes a PE tank finish unit and a PE tank adjustment unit; the PE tank finish unit includes a machine base 1, and the upper part of the machine base 1 There is a moving slot 2, a moving platform 3 is arranged on the moving slot 2, and an adjusting handwheel 4 is arranged at one end of the moving slot 2, and the moving platform 3 is on the moving slot 2 through the adjusting handwheel 4. Horizontal movement, a motor 5 is arranged on the upper part of the moving platform 3, a tool mounting plate 6 is arranged at the power output end of the motor 5, and a flange center circular blade 7 and a PE surface are respectively arranged on the tool mounting plate 6 The blade 8 is provided with a PE inner tank opening fixing frame 9 on one end of the moving groove 2, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com