Preparation method of liqueur

A technique for dew wine and base wine, applied in the field of dew wine preparation, can solve the problems of long storage period, high time cost, slow association process between wine and fruit juice, etc., and achieves soft wine taste, shortened storage time, and obvious fruit fragrance. taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

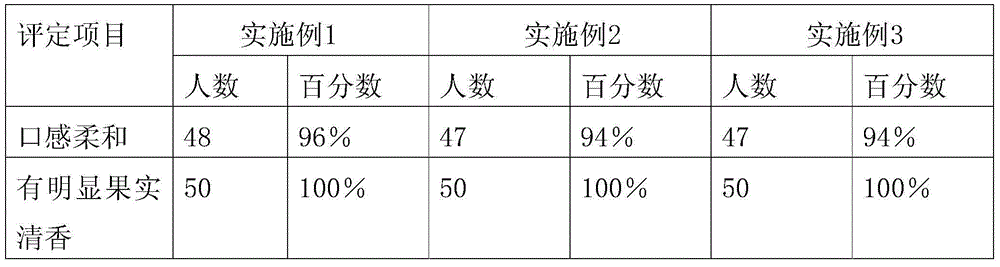

Examples

Embodiment 1

[0017] This embodiment provides a kind of preparation method of dew wine, specifically carries out according to the following steps:

[0018] S101. Blending: Pour 10kg of apple juice into a blending tank, add base wine for blending, accurate measurement is required during blending, and the amount of base alcohol should be added according to the moisture content of the auxiliary materials during blending. The alcohol content of blending is about 1.5% vol; Use an air pump to stir for 5 hours during deployment;

[0019] S102. Clarification treatment and coarse filtration: add bentonite to the blended wine and let it stand naturally for 7 days, then filter with a diatomite filter, the amount of bentonite added is 0.6 g / L.

[0020] S103. Storage: after coarse filtration, physical and chemical data analysis is required every two days, and stored in a blending tank for 10 days at a storage temperature of 25°C;

[0021] S104. Heating: use a heater to heat until 5 minutes after boilin...

Embodiment 2

[0024] This embodiment provides a kind of preparation method of dew wine, specifically carries out according to the following steps:

[0025] S201. Blending: Pour 10kg of apple juice into a blending tank, add base wine for blending, accurate measurement is required during blending, and the amount of base alcohol should be added according to the moisture content of the auxiliary materials during blending. The blended alcohol content is about 20% vol; Use an air pump to stir for 5 hours during deployment;

[0026] S202. Clarification and coarse filtration: add bentonite to the blended wine and let it stand naturally for 7 days, then filter it with a diatomite filter, the amount of bentonite added is 1.2 g / L;

[0027] S203. Storage: After coarse filtration, it is required to analyze the physical and chemical data once every two days, and store it in a blending tank for 7 days at a storage temperature of 30°C;

[0028] S204. Heating: use a heater to heat to 8 minutes after boilin...

Embodiment 3

[0031] This embodiment provides a kind of preparation method of dew wine, specifically carries out according to the following steps:

[0032] S301. Blending: Pour 10kg of apple juice into a blending tank, add base wine for blending, the measurement must be accurate during blending, and the amount of base alcohol should be added according to the moisture content of the auxiliary materials during blending. The blended alcohol content is about 38% vol; Use an air pump to stir for 5 hours during deployment;

[0033] S302. Clarification treatment and coarse filtration: add bentonite to the blended wine and let it stand naturally for 7 days, then filter it with a diatomite filter, the amount of bentonite added is 1 g / L;

[0034] S303. Storage: After coarse filtration, physical and chemical data analysis is required every two days, and stored in a blending tank for 15 days at a storage temperature of 30°C;

[0035] S304. Heating: use a heater to heat until 6 minutes after boiling, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com