Preparation method of powder metal composite sound insulation coiled material

A powder metal, composite roll technology, applied in the direction of sound insulation, building components, etc., can solve the problems of easy rust, poor construction, sound insulation and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

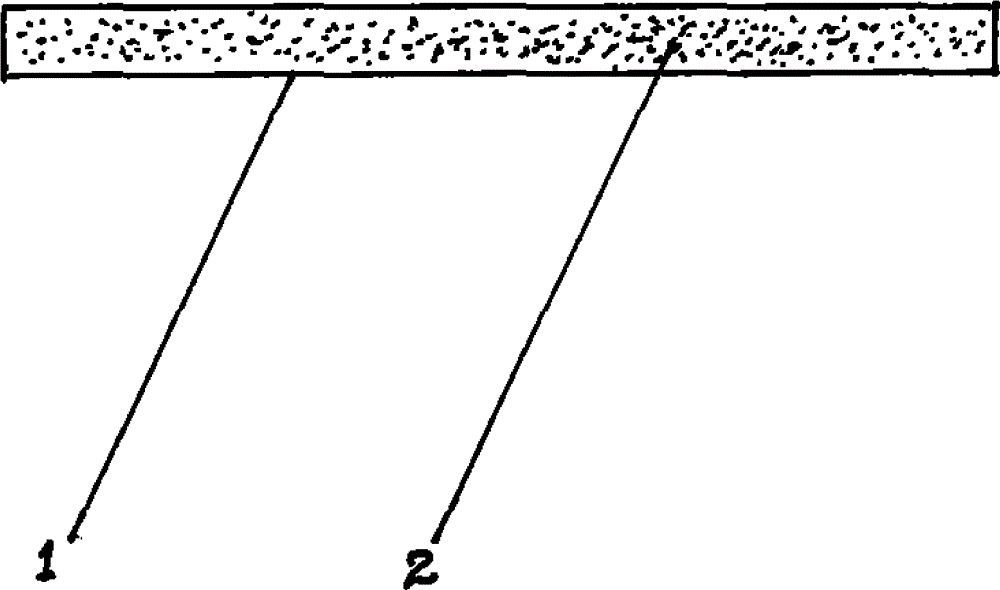

Image

Examples

Embodiment Construction

[0013] Embodiment In the field of building sound insulation, soft elastic materials made of high specific gravity metal powders such as iron and steel are made into coils of different thicknesses, which can play a good role in sound insulation, and its softness and elasticity can be cut with a knife. It is very convenient to use.

[0014] To sum up, the application of powder metal composite sound insulation materials will have a very broad prospect.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com