Optical encoder

A technology of optical encoders and optical patterns, applied in the field of optical encoders, can solve the problems of increasing production costs and difficulties, limiting the maximum positioning resolution of optical encoders, etc., and achieve the effect of high positioning resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

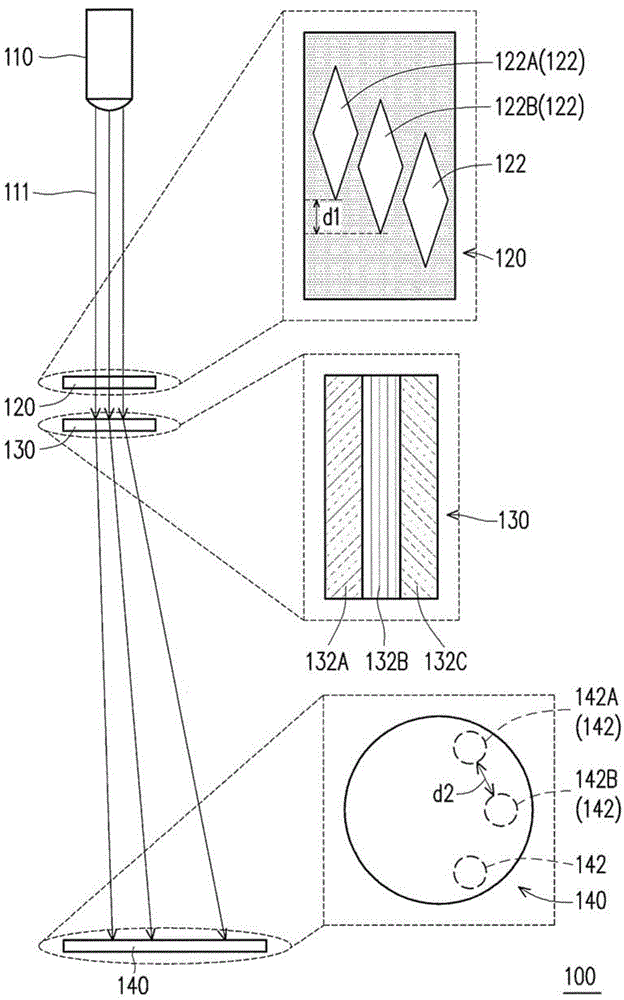

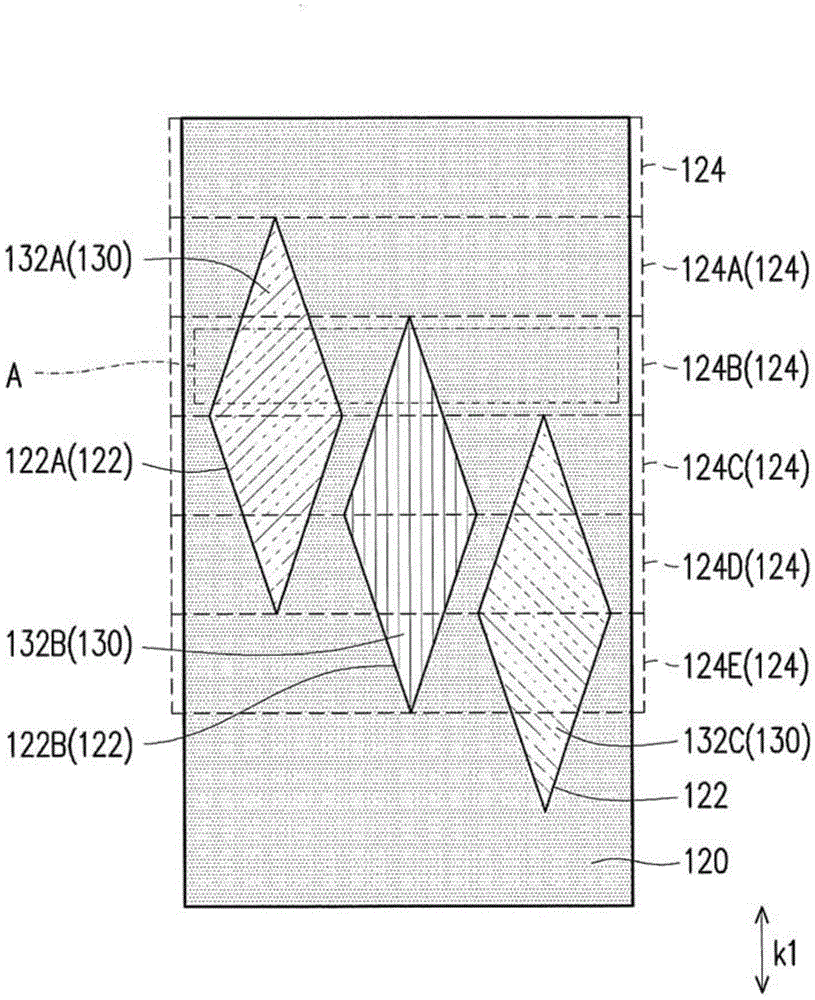

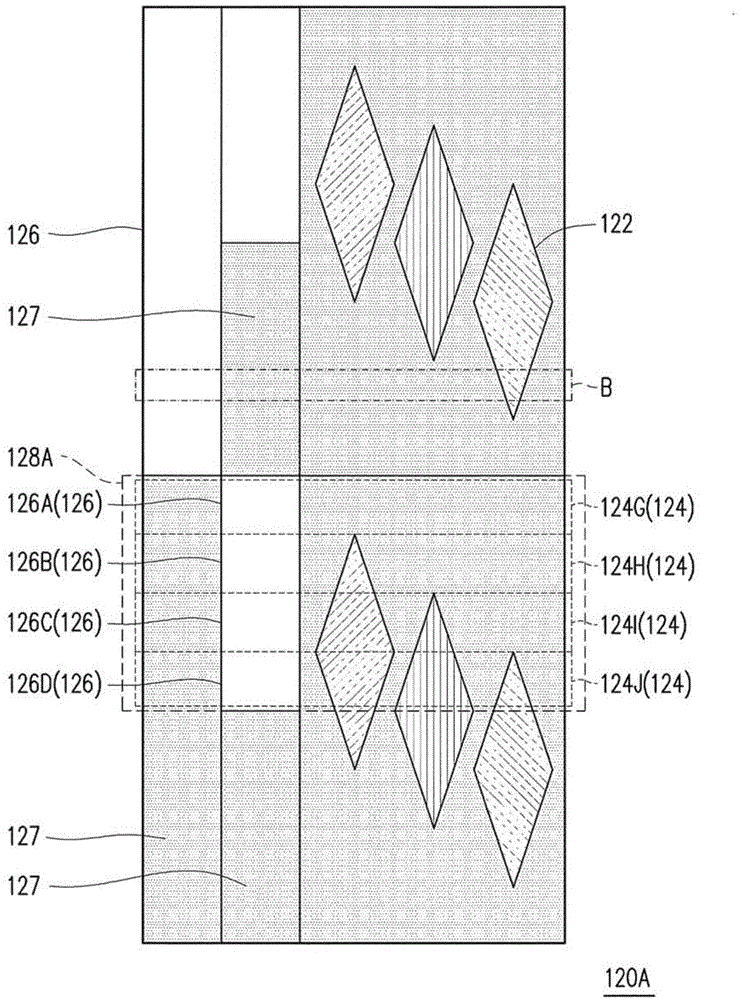

[0062] figure 1 It is a schematic diagram of an optical encoder and a top view of a positioning element, a light splitting structure, and a sensing area according to the first embodiment of the present invention. figure 2is a top view of a positioning element and a light splitting structure according to the first embodiment of the present invention. Please refer to figure 1 and figure 2 , in the first embodiment of the present invention, the optical encoder 100 includes a light emitting module 110 , a positioning element 120 and a light splitting structure 130 . The light emitting module 110 emits a light beam 111 , and the light beam 111 irradiates the irradiation area A of the positioning element 120 . The positioning element 120 includes a plurality of light-transmitting regions 122 arranged in a shifted position, and these light-transmitting regions 122 move into the irradiation area A sequentially. Since the light-transmitting regions 122 are arranged in dislocation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com