Timepiece comprising a repeater mechanism and a control mechanism with an integrated release lock

A technology of control mechanism and locking device, which is applied in the field of clocks and watches, can solve problems such as difficult actuation, and achieve the effect of eliminating operating errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

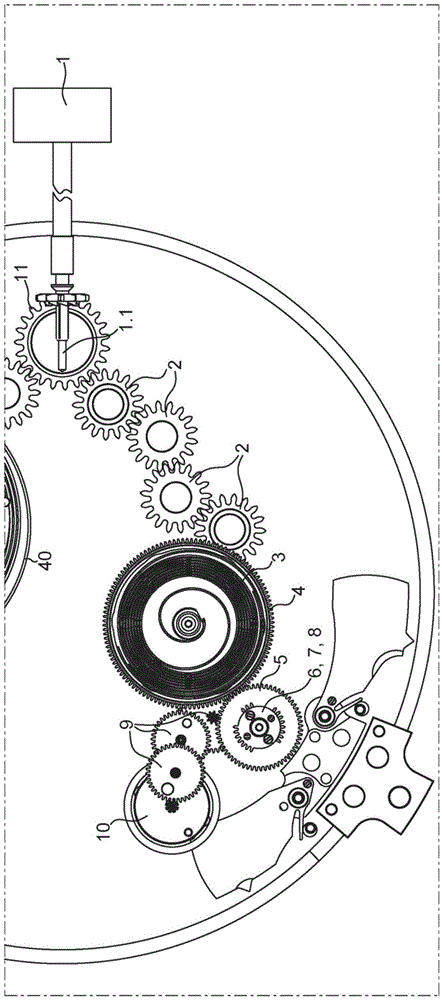

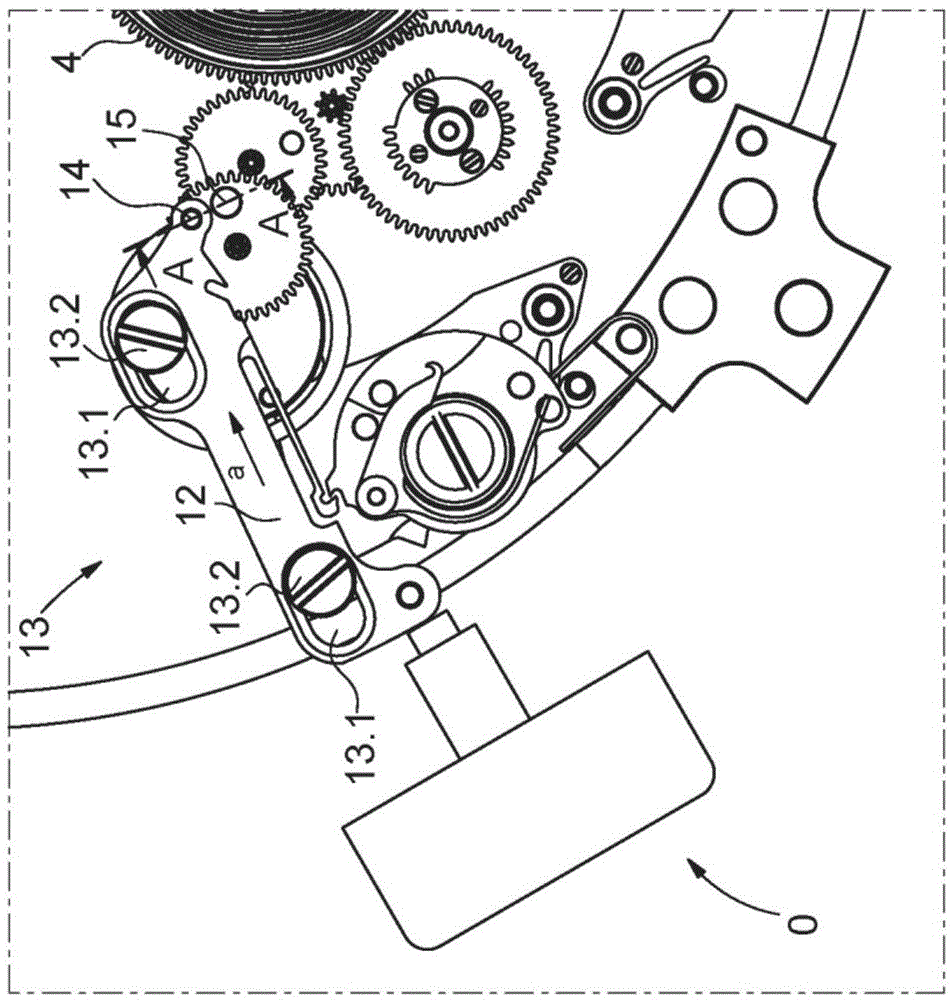

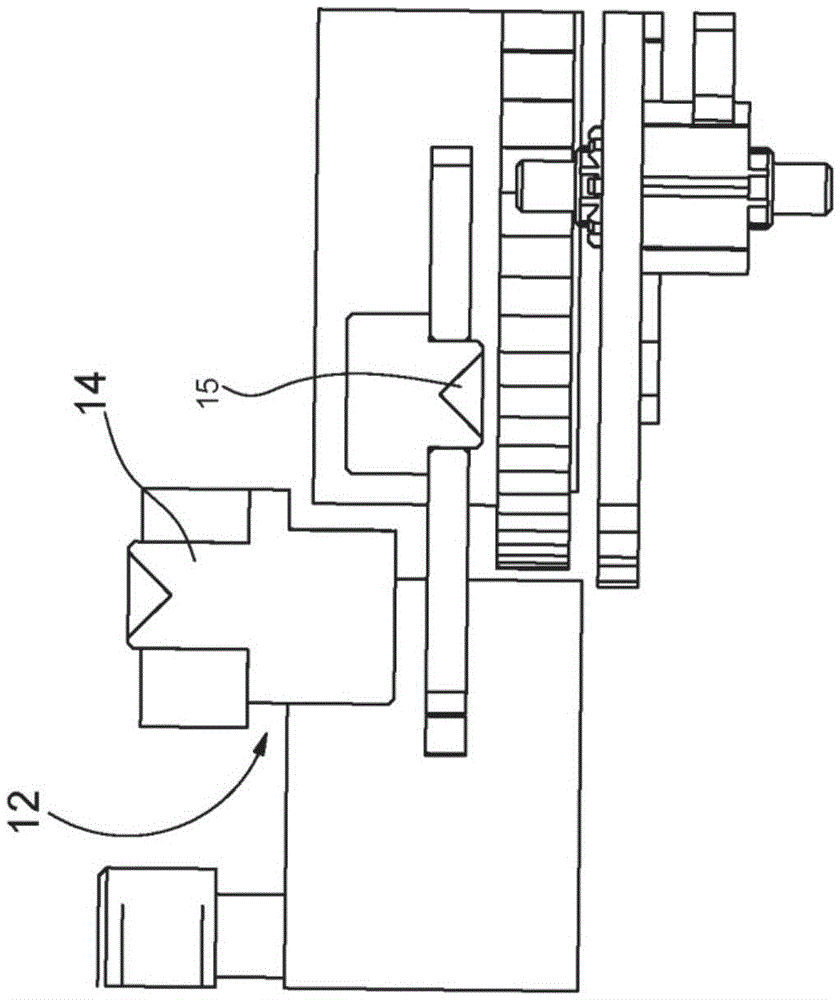

[0030] The figures below each show the structure of the control mechanism with separate winding and release means and the sequence of operations following the release of the striking mechanism which bring the control mechanism into states during the movement of the striking mechanism.

[0031] figure 1 A preferred embodiment of the winding device for tensioning the striking mechanism is shown on the right. By rotating the winding stem 1.1 of the conventional crown 1, the winding drive chain 2 is set in rotational movement. As a result, first mainspring 3 of striking mechanism barrel 4 is tensioned. As is known from clocks with self-winding, the first mainspring 3 is equipped with a sliding tensioner. By the same rotational movement, the second mainspring (not shown) of the timepiece's running barrel 40 is also tensioned; this second mainspring is also equipped with a sliding tensioning device. The two mainsprings are thus tensioned by the rotation of the winding stem until ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com