Steam cutting device

A technology of cutting equipment and steam, which is applied in welding equipment, metal processing equipment, plasma welding equipment, etc., can solve the problems of pressure, fluid supply for steam cutting equipment, etc., and achieve the effect of eliminating operation errors and simple cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

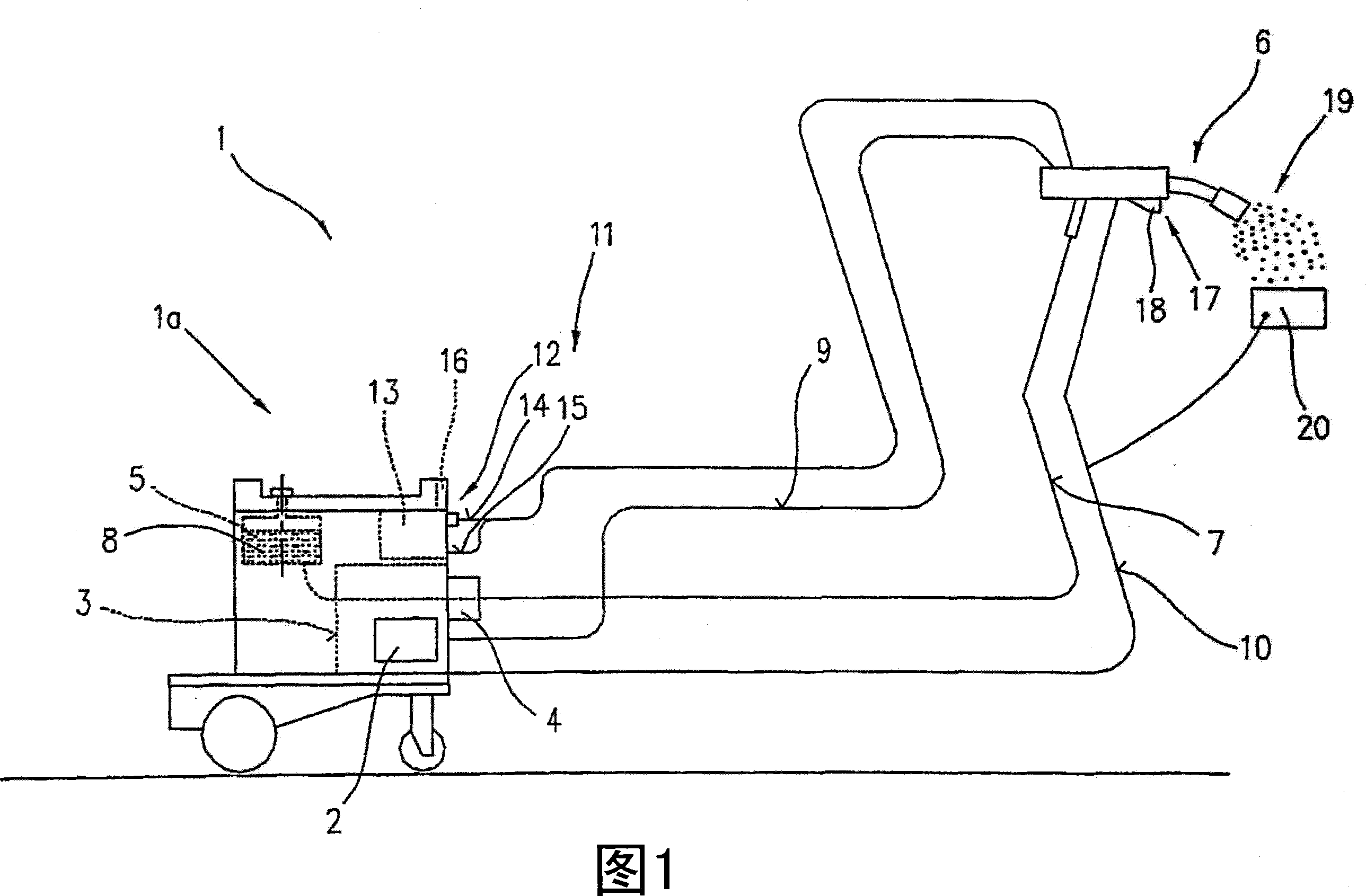

[0025] Figure 1 shows a steam cutting device 1 comprising a basic device 1a for a steam cutting process. The basic device 1 a includes a current source 2 , a control device 3 and a blocking element 4 associated with the control device 3 . The blocking element 4 is connected to the container 5 and the burner 6 via a supply line 7 in such a way that the burner 6 can be supplied with the fluid 8 provided in the container 5 . The energy supply (in particular current and voltage) of the burner 6 takes place via the lines 9 , 10 from the current source 2 .

[0026] For cooling the burner 6 , the burner 6 is connected via a cooling circuit 11 to a fluid container 13 , optionally via an interposed flow monitor 12 . During operation of the burner 6 or the base unit 1 a , a cooling circuit 11 is activated by the control device 3 , so that the burner 6 is cooled by the cooling circuit 11 . To form a cooling circuit 11 , the burner 6 is connected to a fluid container 13 via cooling line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com