In-situ high and low frequency fatigue double-inclined sample rod of transmission electron microscope

A technology of electron microscope and sample rod, which is applied in the direction of circuits, discharge tubes, electrical components, etc., can solve the problems that the maximum tilt angle cannot exceed ±30, the sensor stage is too large, etc., and achieve simple structure, small size, and accuracy high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

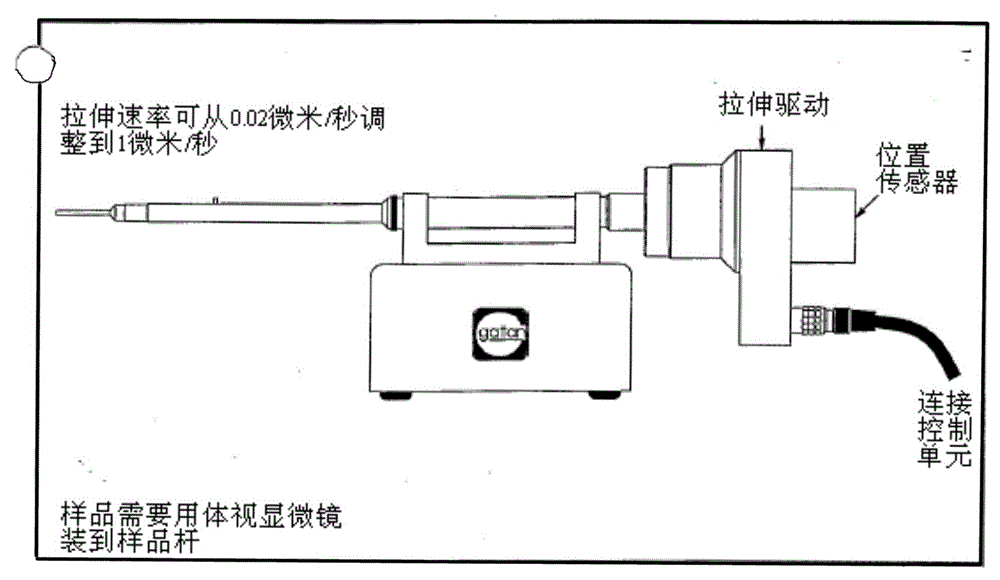

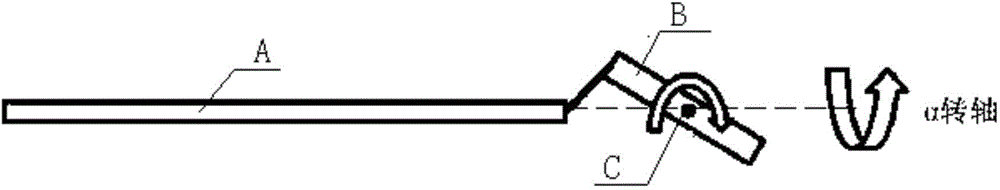

[0033] Such as Figure 5 As shown, the in-situ high-low frequency fatigue double-tilt sample rod of the transmission electron microscope mainly includes a handle 5, a sample rod shaft 4, a sample rod head 1 and a sample loading platform 2 for loading samples. The sample loading platform 2 and The b-axis 9 is fixed, The shaft is rotatably mounted on the 4 head ends of the sample rod. The signal interface of the sample rod 4 is arranged on the handle 5 .

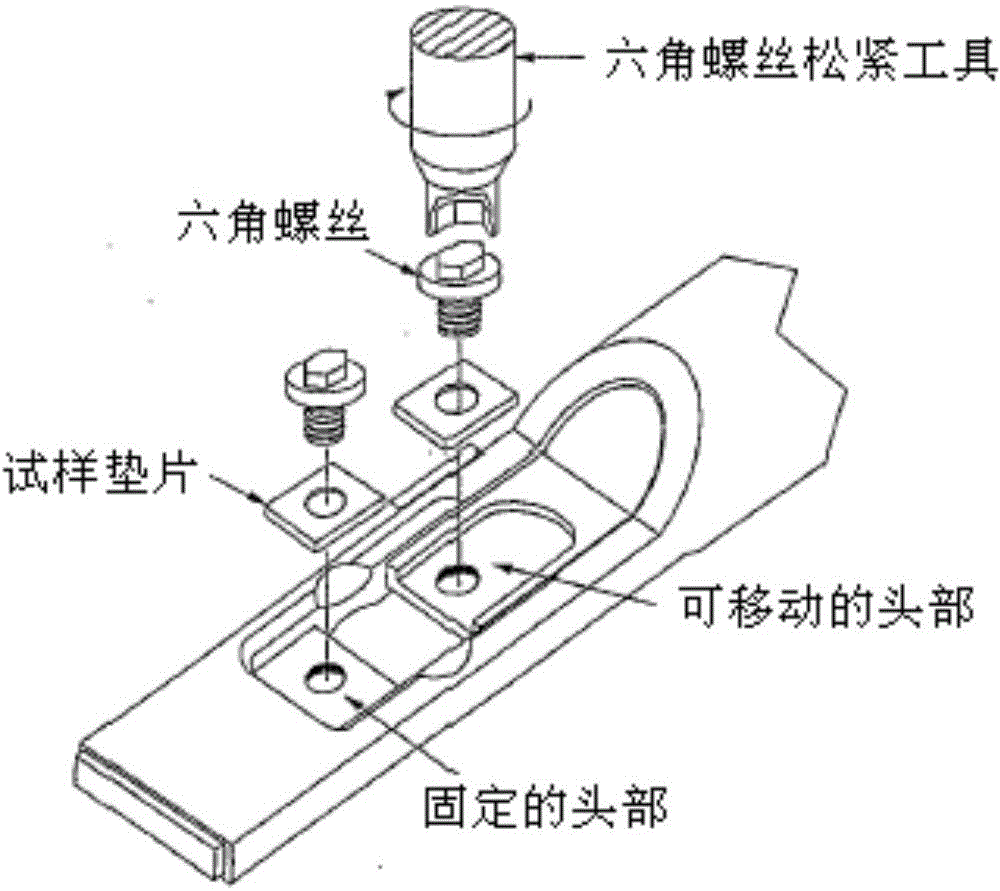

[0034] Such as Figure 6 As shown, the sample loading platform 2 is mainly composed of two loading parts A1, A2 and a connecting part 15. The loading parts A1 and A2 are symmetrically fixed at both ends of the connecting part 15. There is a gap between the two loading parts A1 and A2 that allows them to interact with each other. close to or away from the deformation gap C; each loading part includes its own Shaft 9, fatigue loading member 14 and sample holder 13, The shaft 9 and the fatigue loading member 14 are respec...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap