Injection nozzle introduction device for smelting furnace

A technology of injection nozzles and introduction devices, applied in furnaces, furnace components, gas fuel burners, etc., can solve problems such as accidents, low accuracy and productivity, and achieve the effect of preventing the risk of accidents and easy introduction operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings.

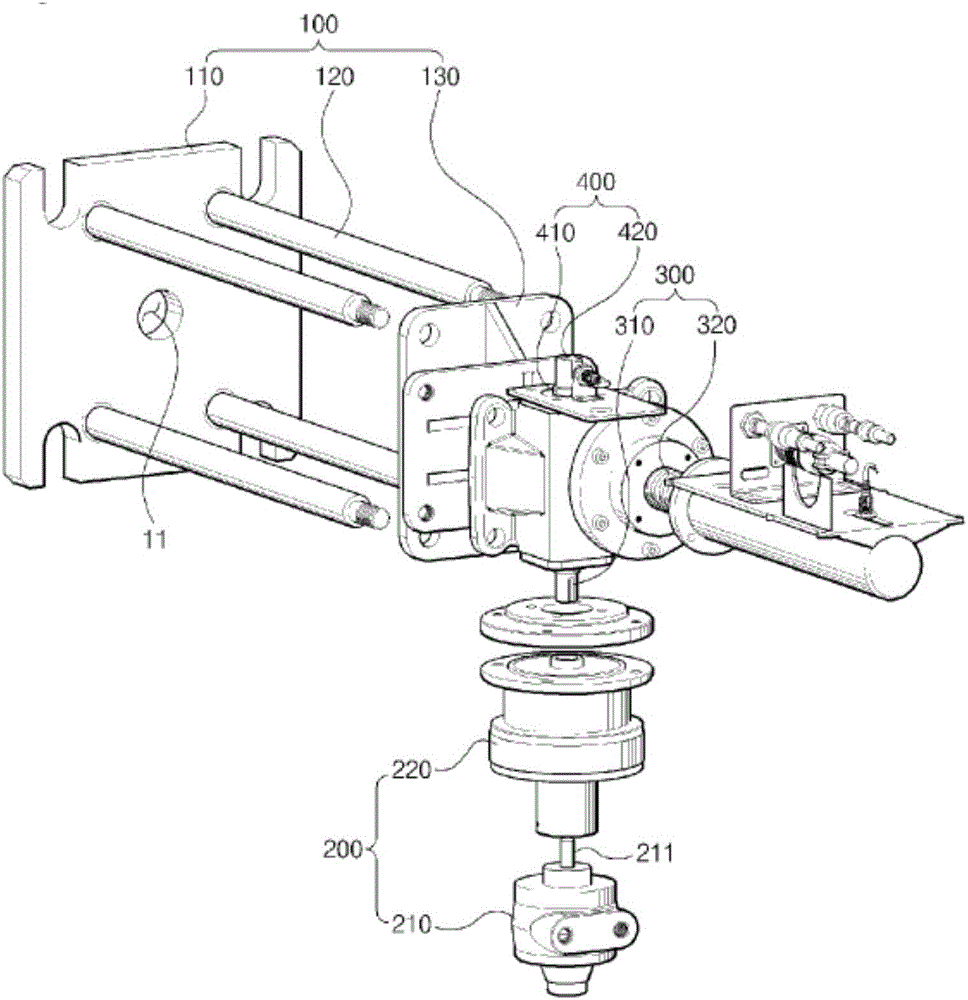

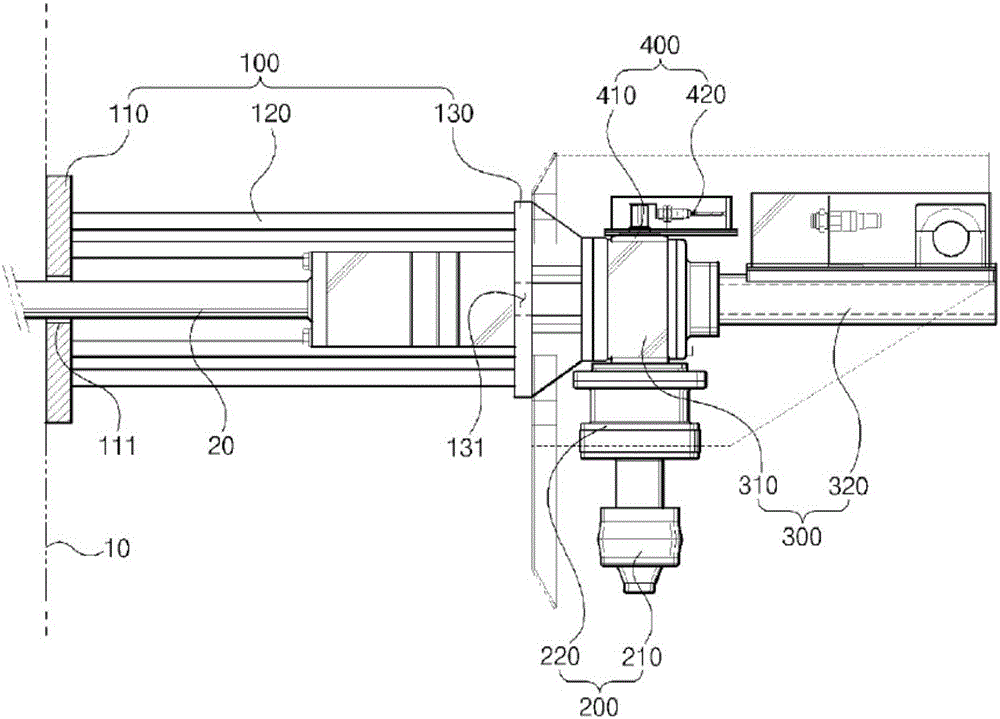

[0018] figure 1 It is an exploded perspective view of an injection nozzle introducing device for a smelting furnace according to an embodiment of the present invention, figure 2 yes figure 1 side view. refer to figure 1 and figure 2 , The injection nozzle introducing device for a smelting furnace comprises a main body (100), a driving part (200), a pushing and moving part (300), and a driving control part (400).

[0019] The main body (100) arranges the injection nozzle (20) and the shaft portion of the pushing and moving part (300) that moves linearly in accordance with the operation of the driving part (200) to be described later so that they are arranged on the same axis as each other. In the supported state, it is possible to guide by sliding and moving. That is, the main body (100) supports the shaft portion of the injection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com