Peanut combine planter with ridging mechanism

A seeder, peanut technology, applied in agricultural machinery and implements, devices for capturing or killing insects, shovels, etc. The effect of flooding, improving peanut yield, and facilitating timely spread

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

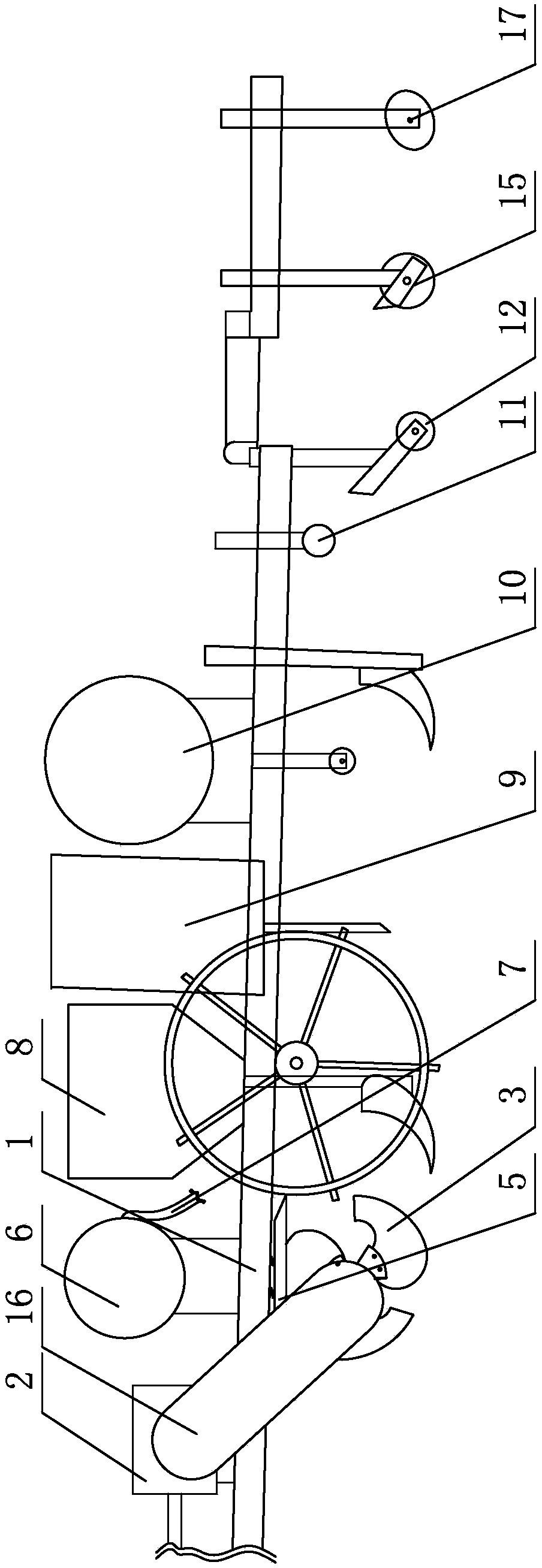

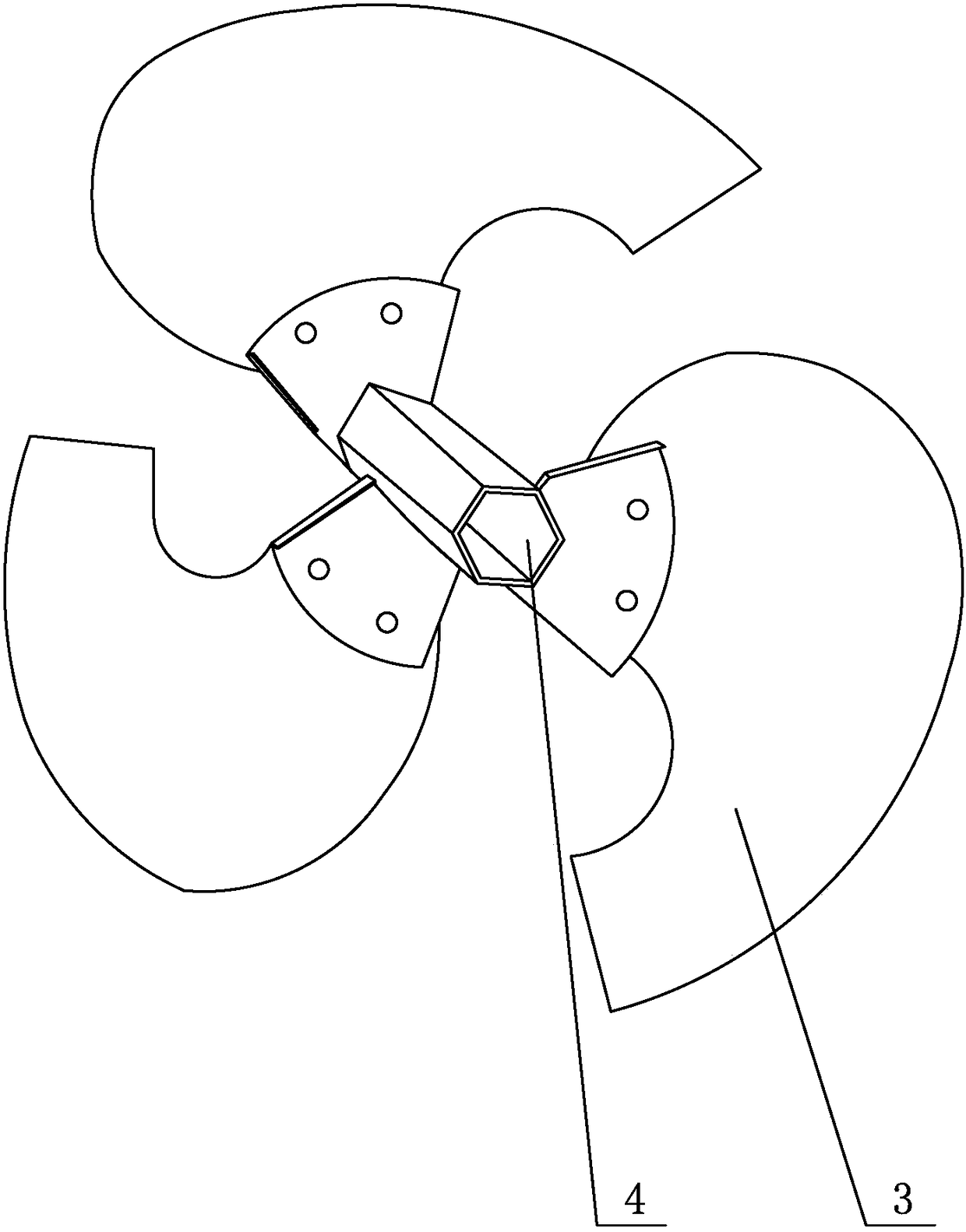

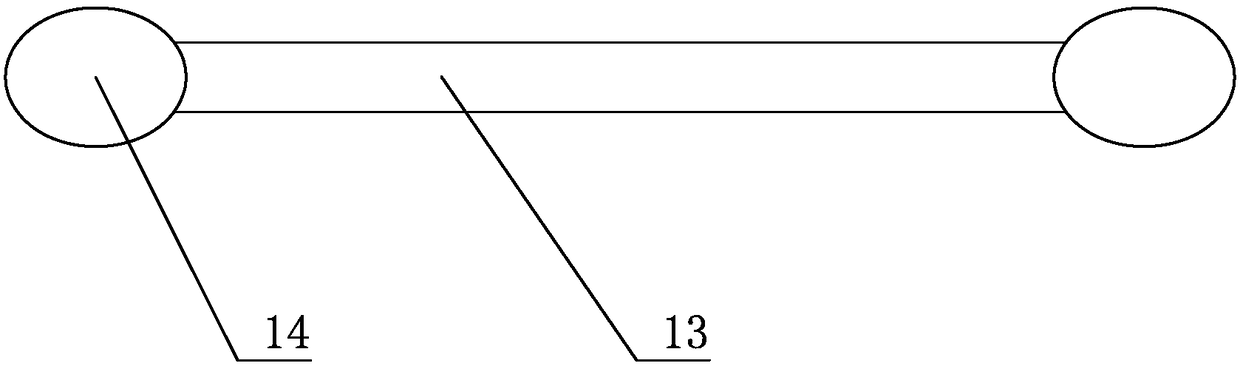

[0024] Such as Figure 1-2 As shown, the peanut combined planter with ridge mechanism described in this embodiment includes a drag device and a frame 1, the drag device is connected to the frame 1, and the drag device is provided with a lifting cylinder corresponding to the frame 1, and the drag device The device is equipped with a power output shaft, the power output shaft is connected to the gearbox 2 through a universal joint, and one end of the transmission shaft of the gearbox 2 is provided with a transmission gear set, the transmission gear set drives the ridge transmission shaft, and the transmission direction of the ridge transmission shaft and the drag device The forward direction is opposite, the ridge drive shaft is fixed on the frame 1 through the bushing, and the ridge knives 3 are fixed at both ends of the ridge drive shaft. figure 1 Middle transmission gear set is blocked by dustproof box 16, and the ridging drive shaft is blocked by ridging knife 3, all not sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com