An automatic feeding straw grinder

A technology of straw pulverizer and pulverizer, which is applied in the direction of agricultural machinery and tools, cutting equipment, application, etc., can solve the problems of inability to meet the safety protection of straw pulverization, the inability to meet the actual needs of production, and the low production efficiency of potential safety hazards. The effect of service life and production efficiency, increased wind power, and high frequency of speed and pressure changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

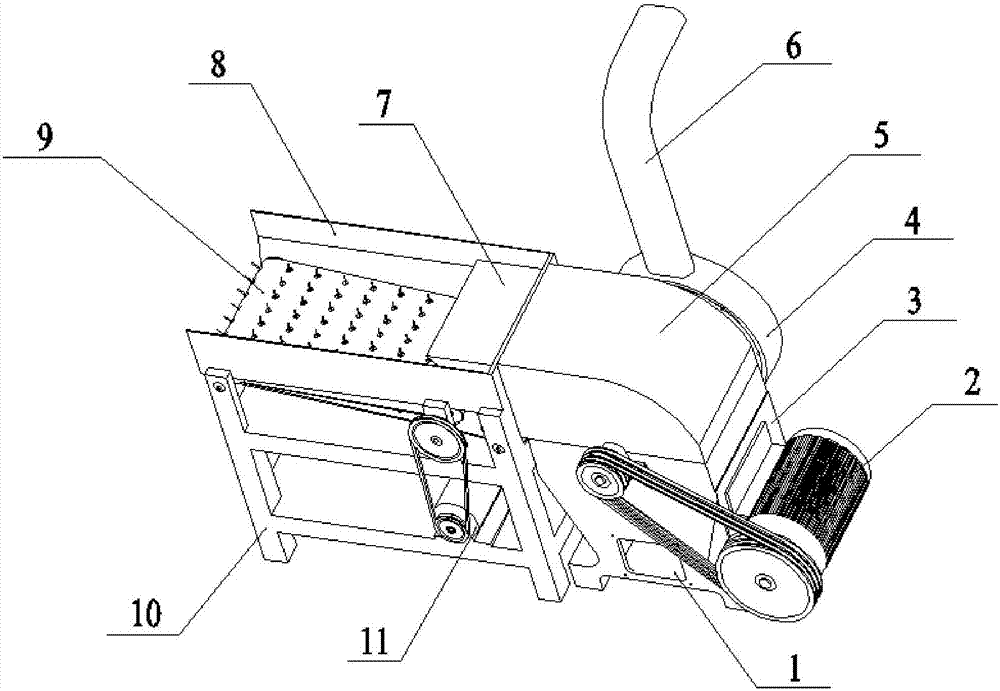

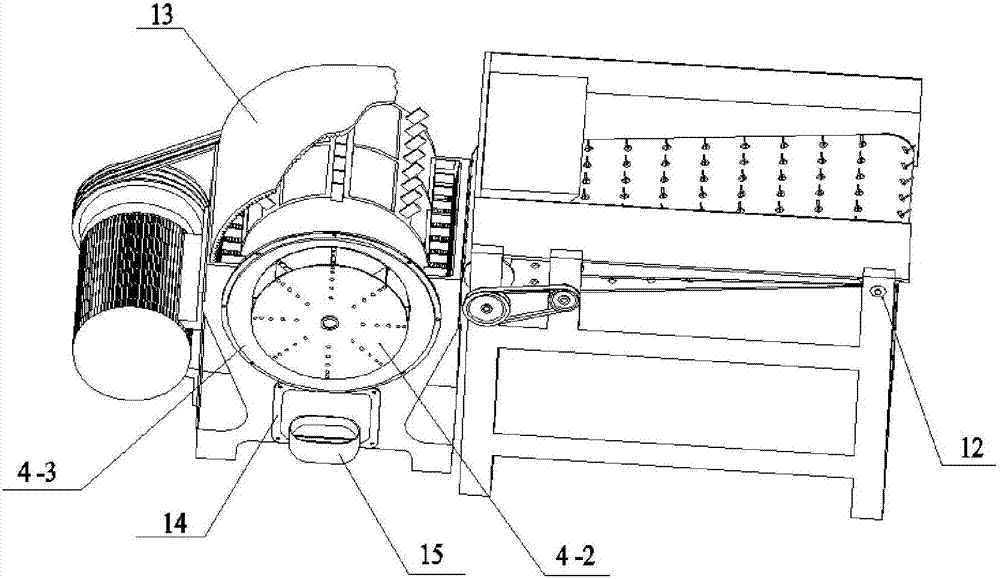

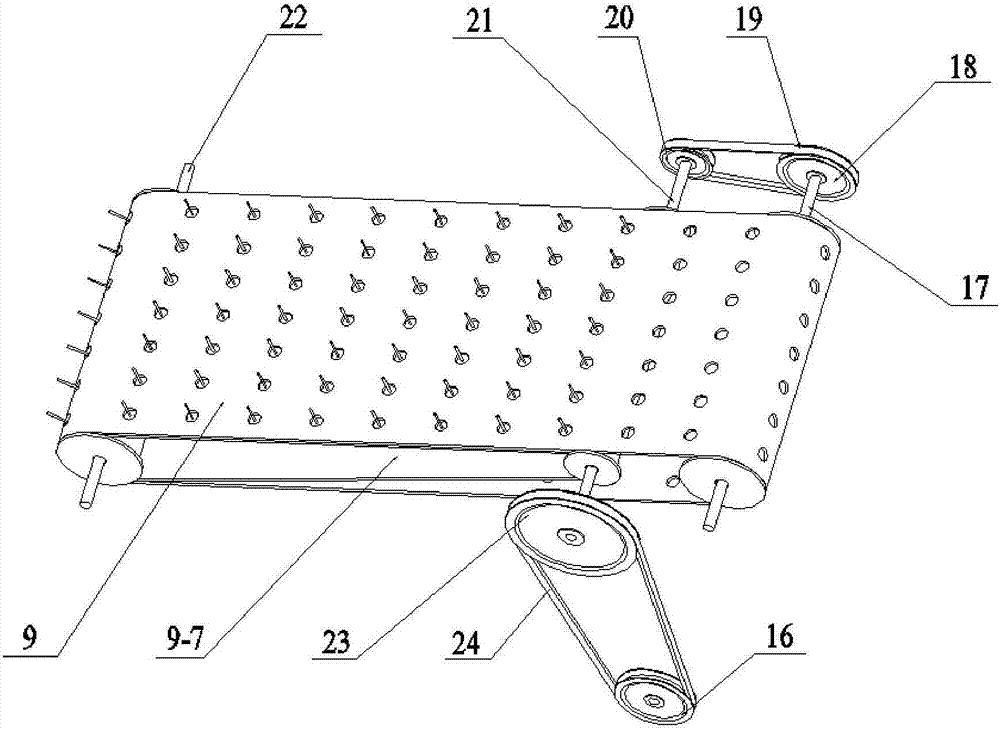

[0023] Such as Figures 1 to 9 As shown, the automatic feeding type straw pulverizer is characterized in that it includes a feeding device and a crushing and discharging device. The feeding device includes a transmission frame 10, and a transmission motor is arranged on the transmission frame 10. 11 and bearing housing 12, the transmission motor 11 is driven and connected with the transmission assembly 9 on the transmission frame 10, the top of the transmission frame 10 is also provided with a feed chute 8 and a material inlet 7, and the crushing and discharging device includes corresponding settings In the crushing frame 3 on one side of the transmission frame 10, the front end of the crushing frame 3 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com