Quick-replaceable filter

A filter and fast technology, applied in the field of separation, can solve the problems of difficult operation, easy leakage of the filter, complicated installation of the filter, etc., and achieve the effect of convenient replacement, easy replacement and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further elaborated below in combination with the accompanying drawings and specific embodiments.

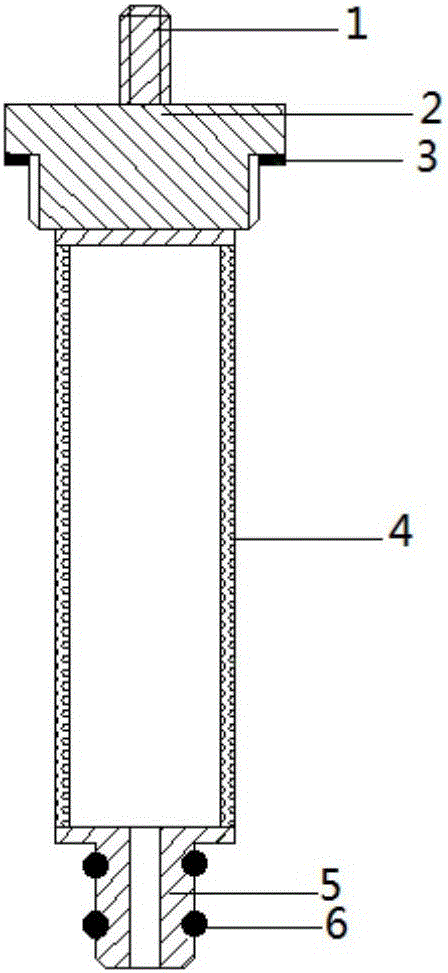

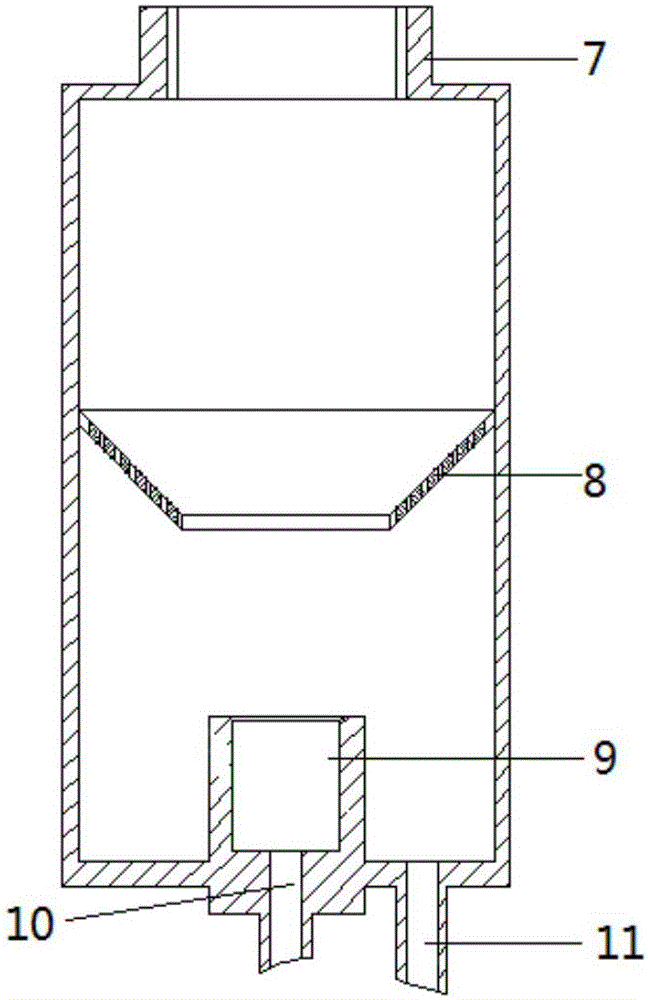

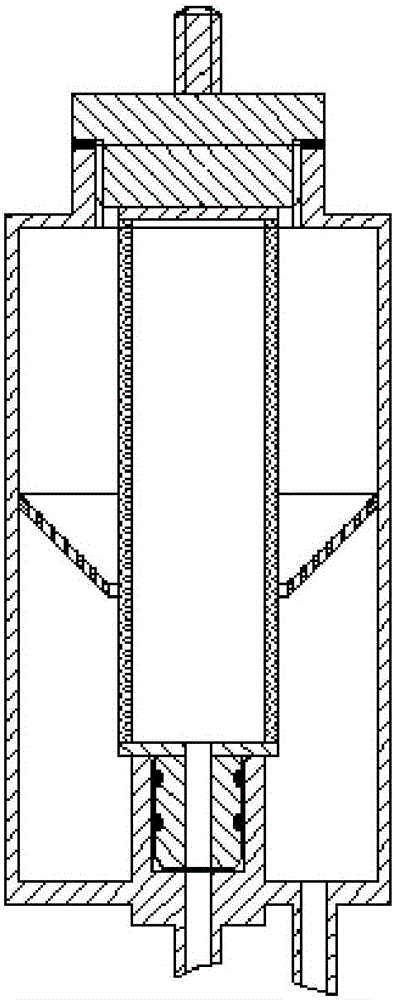

[0025] A filter that can be easily and quickly replaced consists of two parts: a filter element and an outer sleeve. The filter element is installed inside the outer sleeve and connected by threads, such as image 3 shown. Among them, the filter element such as figure 1 As shown, it is mainly composed of an upper end 2, a filter screen 4 and a lower end 5. The upper end of the filter screen 4 is connected to the upper end 2 by welding, and the lower end of the filter screen 4 is connected to the lower end 5 by welding; the structure of the outer sleeve is as follows: figure 2 As shown, the lower end is provided with a liquid inlet 10 and a liquid outlet 11, and the upper end of the liquid inlet 10 is provided with a liquid inlet expansion section 9, which facilitates the installation and sealing of the filter element. In addition, the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com