Equipment for recovering heat energy and waste water

A technology for wastewater and water pumps, used in lighting and heating equipment, filter circuits, water heaters, etc., to solve problems such as heat energy and water waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

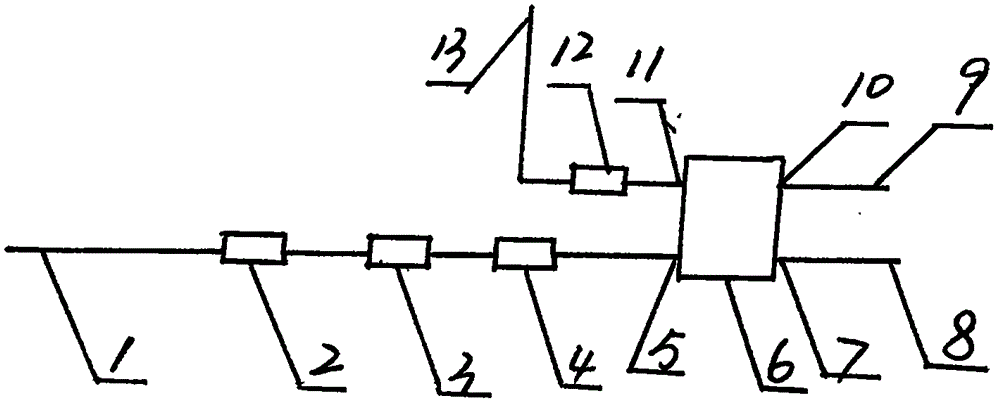

[0012] The present invention will be further described below in conjunction with accompanying drawing.

[0013] The equipment for recovering heat energy and recovering waste water according to the present invention includes a filter 2, a water pump 3, a fine filter 4, a heat exchanger 6, a water flow switch 12 and connecting pipes, and is characterized in that: the water inlet of the filter 2 and the waste water The hot water interface 1 is connected by a pipe fitting, the water outlet of the filter 2 and the water inlet of the water pump 3 are connected by a pipe fitting, the water outlet of the water pump 3 is connected with the water inlet of the fine filter 4 by a pipe fitting, and the water outlet of the fine filter 4 is connected by a pipe fitting. It is connected with the interface 1Q5 of the heat exchanger 6 through pipe fittings, the interface 2Q7 of the heat exchanger 6 is connected with the water inlet 8 of the waste water recovery tank through pipe fittings, the int...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap